ater consumption is a major consideration in large commercial buildings and, with world resources of drinking water at a premium, the need to look further to explore possible solutions for water conservation are much needed.

In recent years, the use of water by building occupants has been the focus, with improved design standards leading to more efficient water fittings and improved system design.

Water-recovery systems have also received attention lately, leading to more buildings incorporating rainwater and greywater recovery systems. However, the water consumed by building cooling systems has largely been ignored, relying on designers’ perceptions of good practice to arrive at suitable and, hopefully, efficient solutions.

The water make-up use for cooling towers (CT) often has been overlooked with large volumes of potable water being wasted.

The main focus of this article is to show how a more sustainable solution can reduce potable water consumption and achieve additional credits for efficient water use within the project environmental assessments.

Most water-based efficiency measures can be analysed relatively simply and in isolation. This is not the case for CT water consumption, where a number of interrelated factors need to be considered to establish optimum solutions.

These include the combined effect of other water-recovery systems, the capital costs of cooling equipment and associated water-treatment systems, and the economic life of each system including consequential operating costs. By analysing these competing considerations holistically, an optimal solution can be achieved.

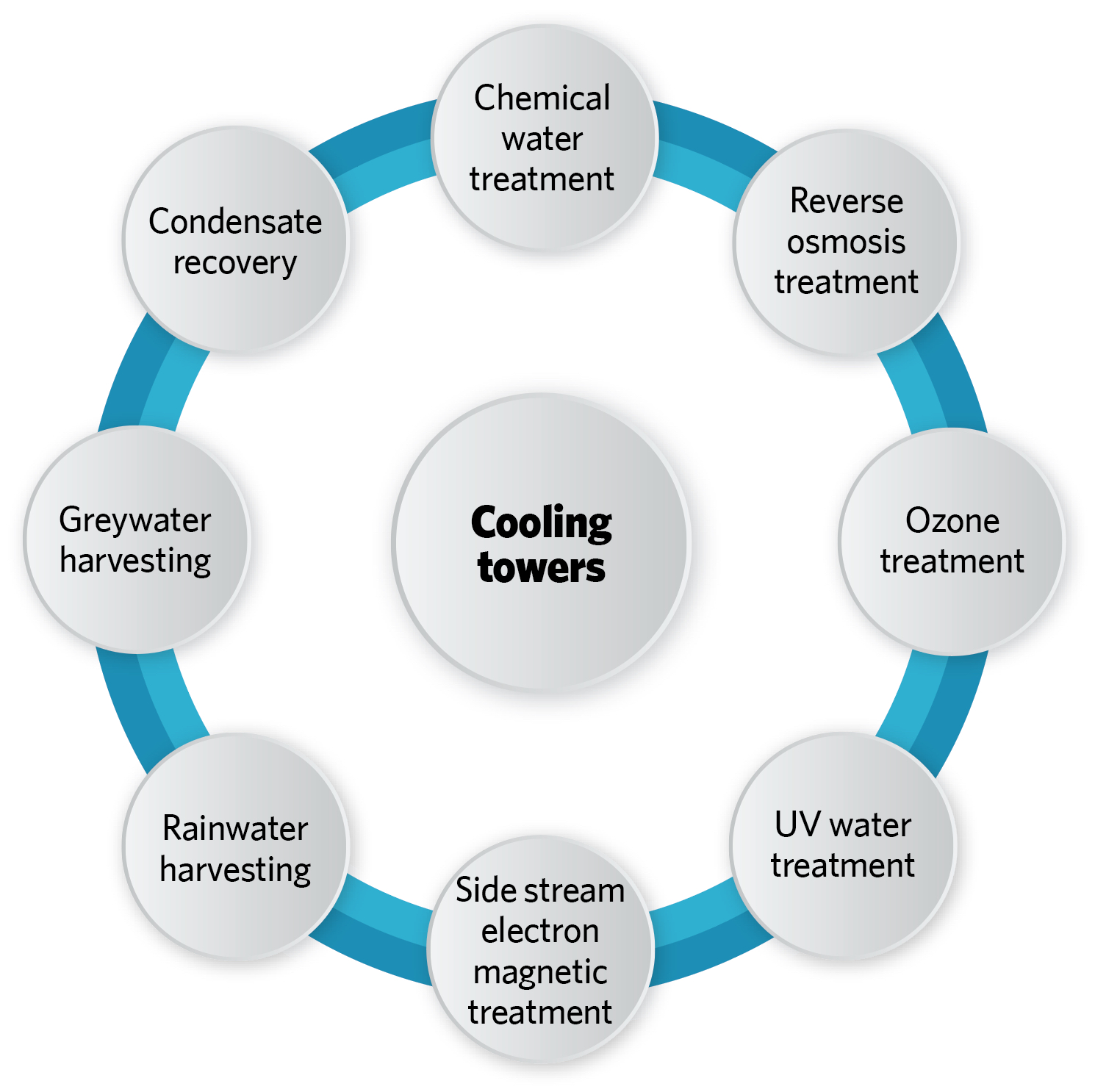

The water treatment options considered here include a number of water-treatment processes, which are widely used in the industry and have been considered for efficient treatment of the CT make-up water. They are:

- Chemically treated CT with reverse osmosis (RO) treatment

- Chemically treated CT with packaged side stream and membrane filtration treatment

- Chemically treated CT with side stream separator and electromagnetic (EM) pre-treatment

- Ozone treated CT

- Ozone treated CT with RO pre-treatment.

A notional building with a fixed heat rejection load was used to allow analysis and comparison of the water savings with these solutions.

The notional building is very representative of many new large commercial developments currently being constructed, where CTs provide the only viable means of rejecting excess heat.

Typically, these buildings, because of the business activities required by tenants, have highly specified systems with large internal cooling loads that result in the building being in a cooling mode for the majority of the year.

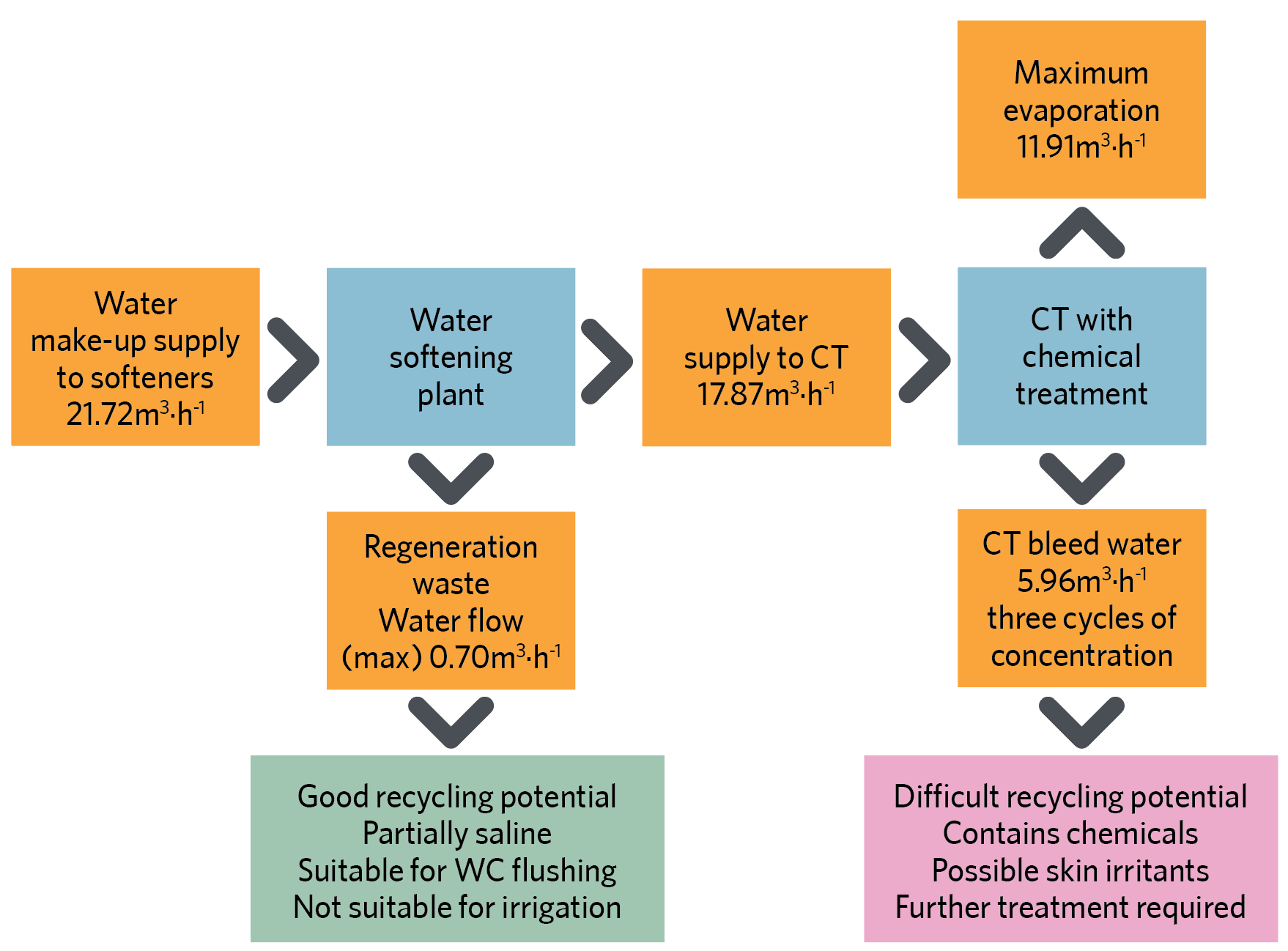

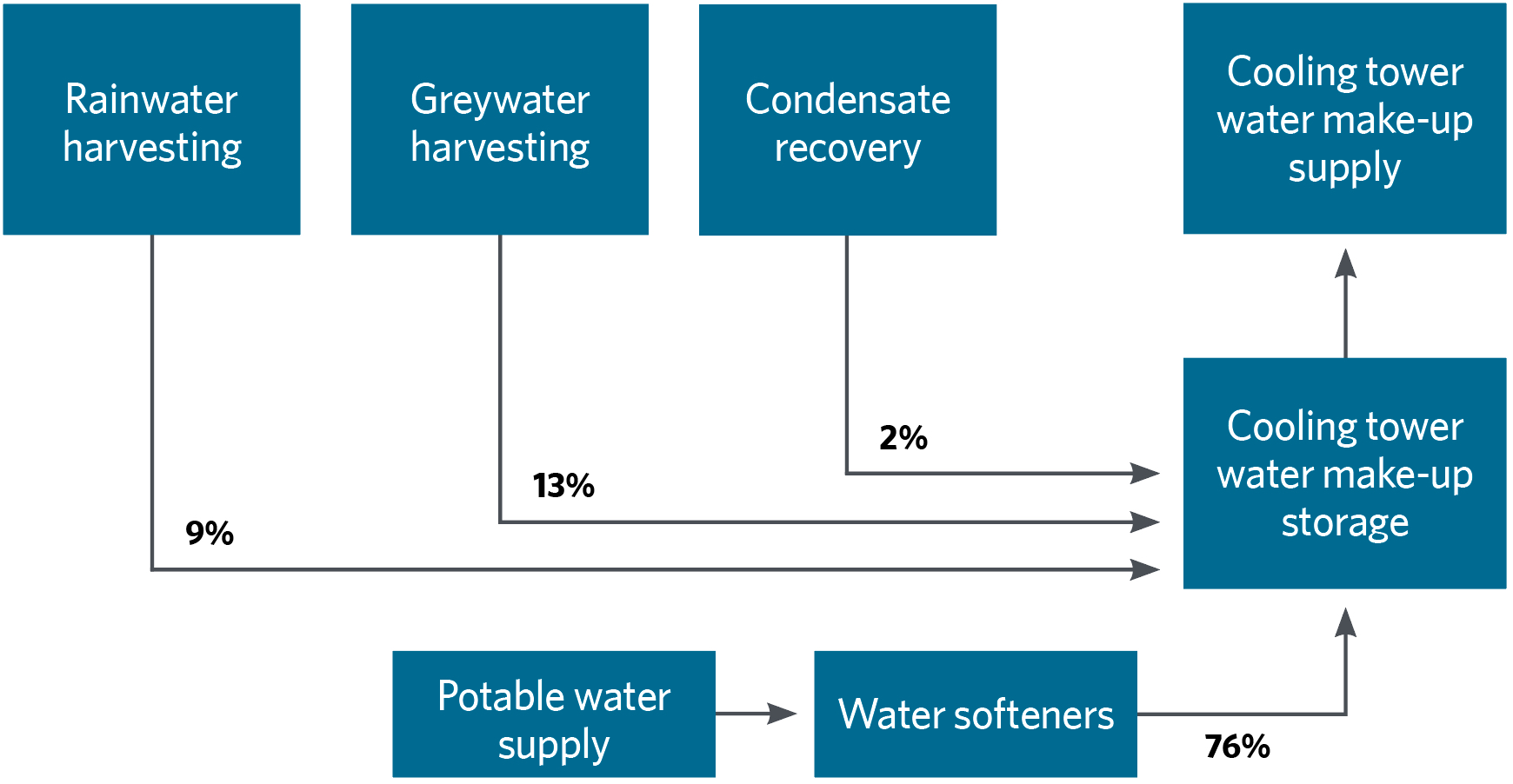

Figure 1: Notional building CT water balance diagram

Dynamic thermal modelling of the notional building cooling capacity allows for the assessment of the cooling capacity for every hour, 365 days of the year. From this raw data, annual profiles of the cooling load can be summarised to allow the water consumption to be assessed in more detail for each option.

The notional building cooling towers consume 22m3.h-1 during a peak summer day with 261 work days that can be extrapolated as approximately 45,936m3.y-1 without seasonal variations (Figure 1).

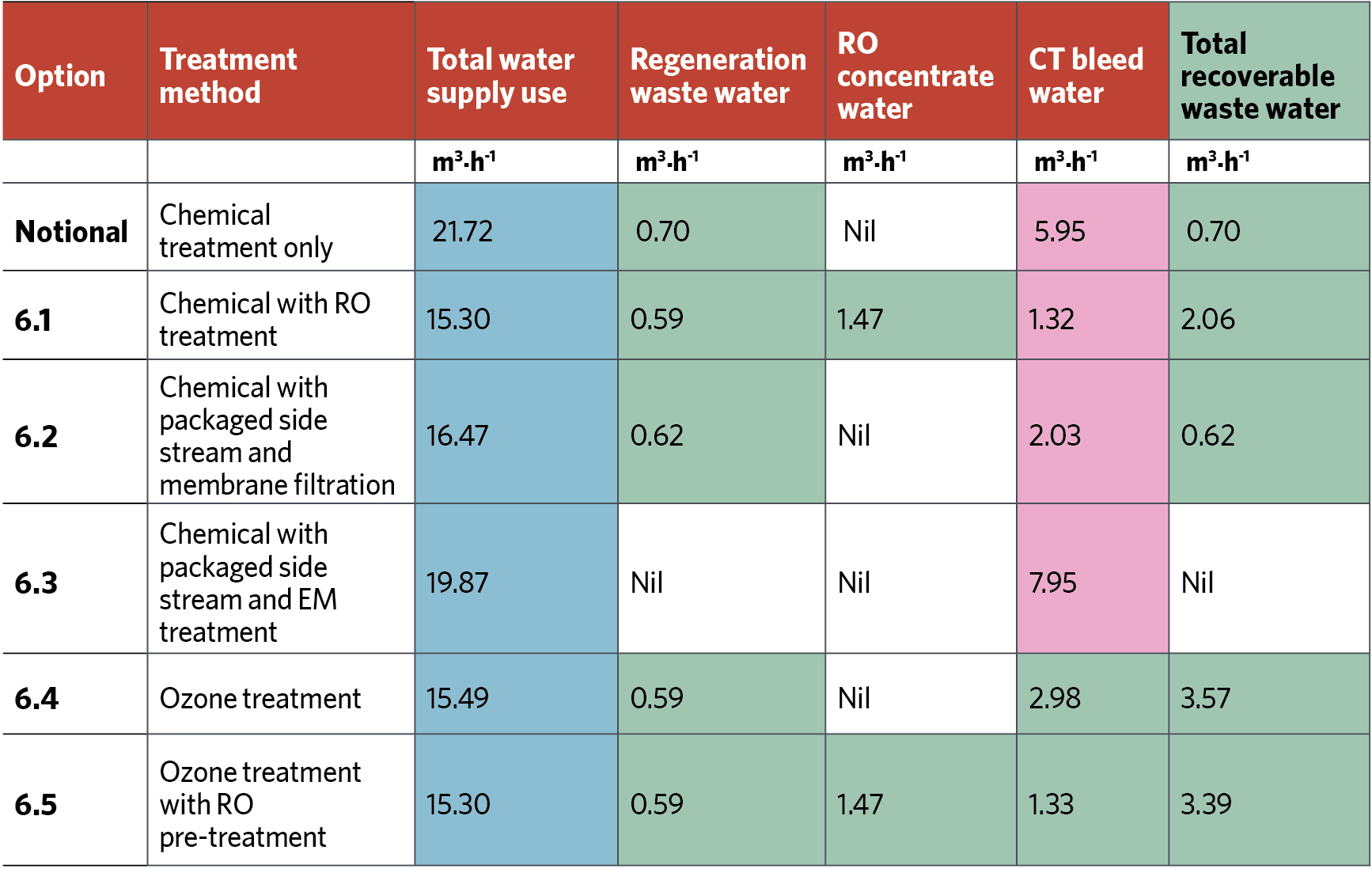

Table 1 shows the overall water consumption for the notional building and each option based on the maximum peak load excluding any water-recovery systems.

It should be noted the CT bleed water figures highlighted in pink cells are not suitable for recovery due to the levels of chemicals present in the water.

In terms of recoverable waste water options, using ozone appears to be the most efficient, with option 6.4 being slightly more efficient resulting in the highest recoverable water figure of 3.57m3.h-1. This is a recoverable water saving of 2.87m3.h-1.

Table 1: Water use and recovery summary (excluding water use recovery systems)

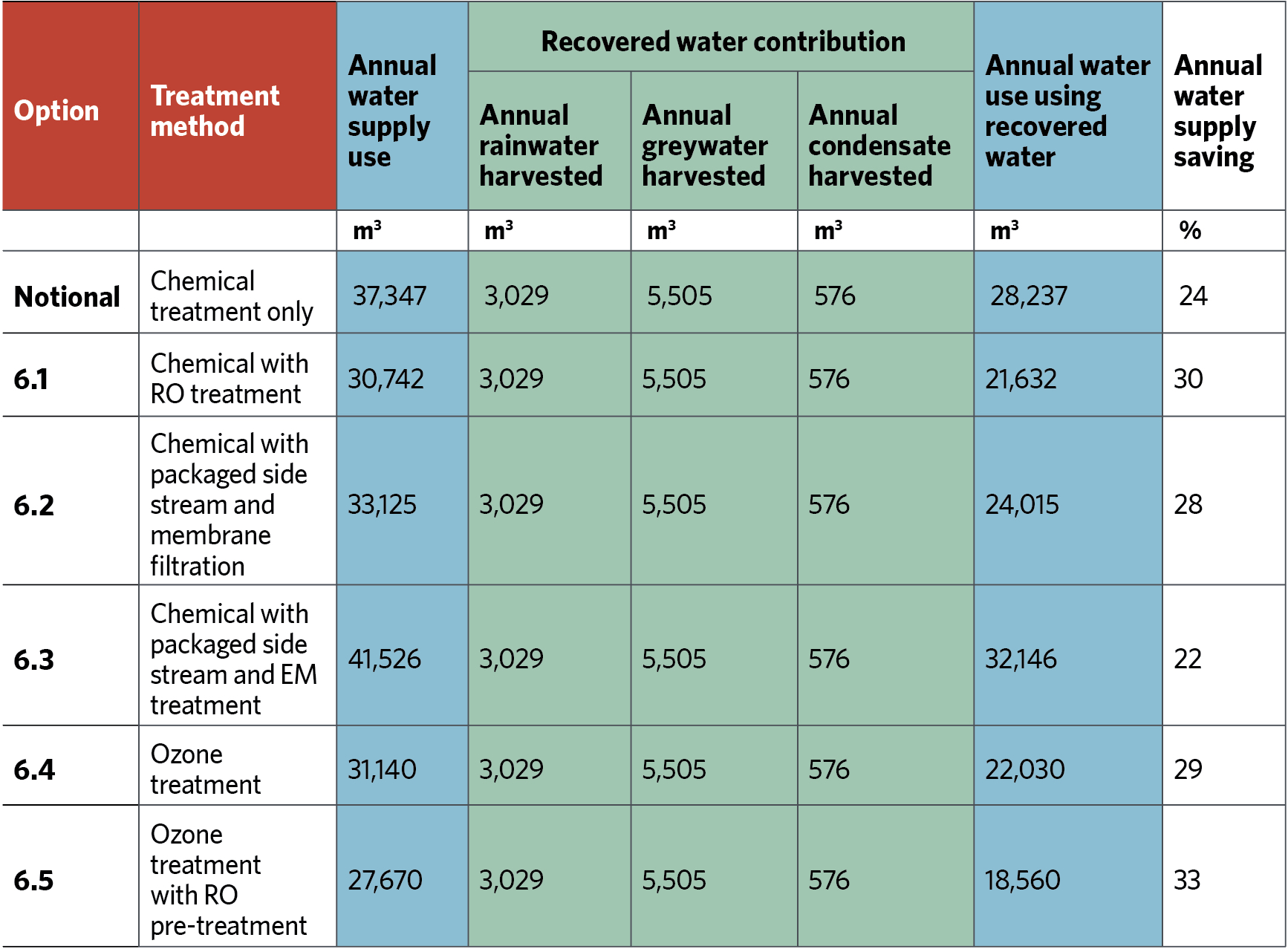

With further consideration of the use of water-recovery systems from other sources, such as rainwater, greywater and condensate, this saving can increase to 33%.

Table 2 shows the percentage savings against the overall annual water consumption for each option, with option 6.5 ozone with RO providing the highest saving of 33%.

The results have shown a potable water saving of 24% can be achieved on the notional building by using conventional chemical treatment for the cooling towers with the introduction of non-potable water for this process. Using rainwater harvesting, greywater recycling and condensate recovery can cut the cost of potable water supply and waste treatment by approximately £10-14,000 per year (see Figure 2).

However, other factors, such as water treatment and equipment costs, should be considered to get a balanced view of the water treatment options.

The results also show the importance of maximising the potential for water-recovery systems within the building, as this increases the options that can be used to maximise the water savings to gain additional environmental assessment points or credits.

Breeam and Leed are the two most widely recognised environmental assessment methodologies used globally in the construction today. Historically, Breeam has been used in the UK, but increasingly international clients are asking for the US Leed assessments to be used too.

Table 2: Total water use and recovery summary (using water recovery systems)

It is not currently included specifically within any Breeam certification requirements to reduce or limit the volume of water used during this process. However, there are credits available for the reduction of water consumption (Wat 04 Water Efficient Equipment) for all major processes, but the onus is on the designer to identify these.

In addition to the water consumption credits, there are innovation credits available that may be gained if water consumption can be reduced due to the inclusion of alternative treatment methods that, together with the use of water-recovery systems, show exemplary performance levels.

In contrast, the USGBC Leed certification requirements have included a specific water efficiency credit for CT water usage. The intention of the credit is to conserve water used while controlling microbes, corrosion and scale within the condenser water system.

One point is available if the following five parameters are not exceeded in the maximum concentrations up to a maximum of 10 cycles. This requires water analysis to be carried out, including measuring maximum concentrations.

Alternatively, two points are available under the following two options:

1) If a minimum of 10 cycles of concentration can be achieved by the CT by increasing the level of treatment

2) Meeting the maximum number of cycles with 20% recycled non-potable water.

A 20% water saving is significant when you look at the volume of water used for the evaporative cooling process.

To give consideration in terms of a single solution is difficult, due to the cost implications with the proposed treatment options, and the material selections required to suit, having impact on both capital and operating costs.

Figure 2: Typical combined water use recovery system

To summarise, there are a number of considerations to be taken into account when seeking the optimum solution, which will vary according to project requirements. Each water treatment option would be suitable for use as CT water make-up but, if combined with other water-recovery systems within the building, the overall consumption of potable water for mechanical uses can be reduced by approximately 22-33%.

Significant water savings are possible with the water treatment options considered, with annual water costs being reduced by up to £14,000.

It is worth noting the notional building analysis used UK weather data, and savings would be even greater in other regions such as the Middle East.

Additionally, all the options are above the minimum 20% recycled water figure required to achieve the additional Leed credit for water efficiency associated with CT water use.

Such solutions will become more common as the sustainability accreditation for new developments drive the need for these water-saving methods. A combined approach, which includes this water usage within the overall project water balance, will make a significant contribution to reducing overall water consumption in new buildings

- Andrew Russell MCIBSE MSoPHE is a project director at Hilson Moran in Qatar and has an active role in the SoPHE Middle East regional group