Outdoor air quality sensor

Adam Taylor – CEO ARM Environments

We don’t seem to be able to talk about any challenges these days without adding the word crisis afterwards. Climate Change Crisis, cost of living crisis, energy crisis and air quality crisis. The latter two are intrinsically linked, and in many cases have opposing priorities.

The latest version of Approved document L of the building regulation, conservation of fuel and power came out in 2014, but has been updated as of 3 February 2023. The latest version of Approved Document F (ADF) was updated in 2022.

Both approved documents took effect on 15 June 2022 for use in England. They do not apply to work subject to a building notice, full plans application or initial notice submitted before that date, provided the work for each building is started before 15 June 2023.

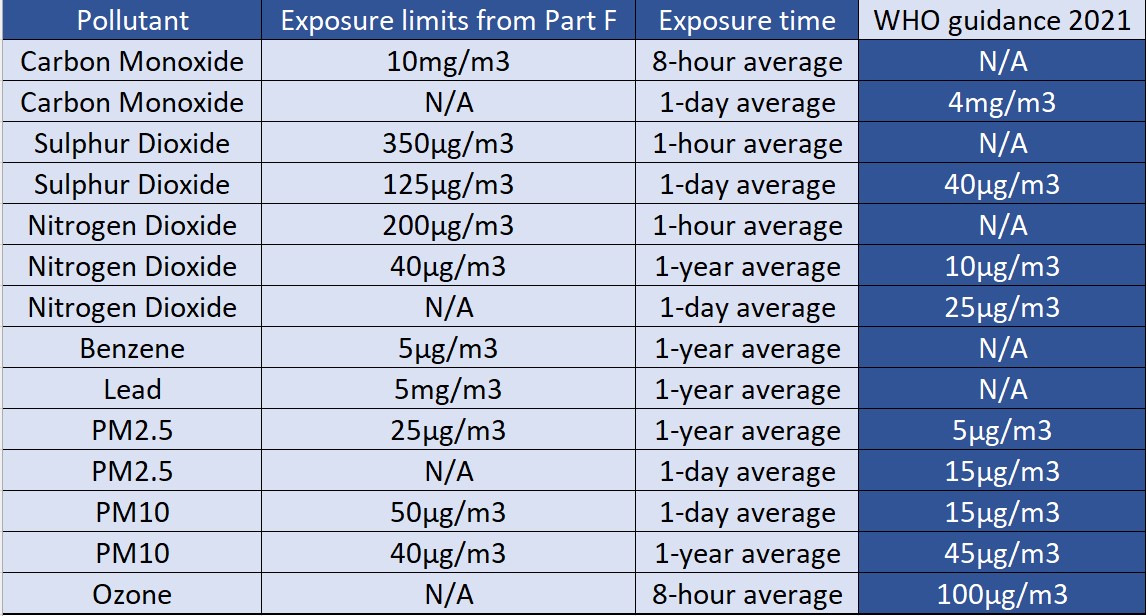

Despite being launched after the updated World Health Organisation (WHO) pollution limits were released, the update of part F, does not include particularly stringent levels for outdoor pollution drawn into buildings. This is a missed opportunity to improve people’s health and comes as a surprise given increased awareness about the health impacts caused by air pollution and considering the long periods of time that these documents remain in force. The latest in a long line of air quality-linked scientific reports indicates that air pollution is linked to worsening symptoms of osteoporosis.

Approved document F: Section 2: Minimising the ingress of external pollutants.

This section states that “ventilation systems should be designed to minimise the intake of external air pollutants” if “the pollutant values in the location of the building exceed any of the limits in Table 2.1” or if the building is located near to any sources of significant local pollution.

Section 2.6 of ADF states that where sources of pollution vary with the time of day, such as urban road traffic, it may be acceptable, for time-limited periods, to take one of the following actions.

- Reduce the flow of external air into ventilation intakes.

- Close ventilation intakes when the concentrations of external pollutants are highest.

This allowance is a great opportunity for reducing energy, reducing filter change intervals AND improving indoor air quality. It is an acknowledgement that sometimes outdoor air is not always “fresh air”, and that the decision whether to be ventilate should be based on data rather than assumptions.

There are two data source options for controlling ventilation rates according to outdoor pollution levels. The first is to mount an outdoor air quality sensor near the AHU intakes, the second is to connect the BMS to an outdoor air quality API with live modelled data.

If outdoor pollution levels are consistently higher than those included in ADF Table 2.1, or if the building being constructed is targeting healthy building standards like WELL or AirRated, appropriate air cleaning solutions will need to be applied to the AHUs bringing air in from outdoors.

Where any of the following components are included in HVAC installations, the maximum specific fan power (SFP) for an air distribution may be increased.

- High-efficiency particulate air (HEPA) filter: add 1.0W/(l·s).

- Humidifier/dehumidifier: add 0.1W/(l·s).

- Active chilled beams: add 0.3W/(l·s).

- Transpired solar collector: add 0.3W/(l·s).

For the majority of buildings, these are all fairly niche pieces of equipment, so their extra energy consumption allowance is not having a big impact on the built environment as a whole. No allowance is given in Part L for the particulate or molecular filtration required to satisfy ADF section 2. This is going to give building designers a real headache when trying to comply with both pieces of legislation.

It does not seem that the government is going to take significant action to address air pollution in the short term. Ella’s Law passed successfully through the House of Lords, but is has stalled in the house of commons. Recent government data showed that the country exceeded its own legal limits for PM2.5 in 2021, so this is going to be a challenge for a few years while the current approved documents are in force. Despite the challenges faced because of Part L’s lack of leniency with specific fan power, there are innovative solutions that can be deployed to reduce the amount of pollutants entering buildings without increasing energy consumption.

In the industry, there is a rigidly held assumption that filter grades cannot be increased without increasing pressure drop and therefore energy consumption. It is true that the type of low-cost basic bag filter typically provided by AHU manufacturers in new units will typically have a high pressure drop relative to its filtration efficiency. As an example, a low cost 8 pocket ePM1 60% filter with an “E” energy rating has an initial pressure drop of 120Pa, and will consume 2189kWh per annum. A higher filtration grade 10 pocket A+ energy ePM1 85% filter has an initial pressure drop of 65Pa and an annual energy consumption 882kWh. Specifiers do not have to accept the filters suggested by the AHU manufacturer, specification of high performance particulate filters needs to become more commonplace.

When it comes to molecular filtration, to limit the ingress of nitrogen dioxide and sulphur dioxide in order to comply with Part F, activated carbon filters will be required. Conventional carbon filters can add a significant pressure drop (~90Pa clean) to an HVAC system. Molecular and particle combined filters are available, saving on total pressure drop, but the long-term performance of these is limited. Typical final stage filters will take many months to reach their efficient dust loading, at which point they should be changed. Conversely, the small weight of carbon contained in combined filters, will quickly saturate and will no longer remove gaseous contaminants. For this reason, we recommend utilising pre-filters with combined ePM10 particle filters and gaseous removal, as the dust loading and saturation of these filters will occur at a similar time. As pre-filters are more regularly changed than final filters, the relatively low weight of carbon in the pre filters becomes less of an issue. The pressure drop of a combined molecular and ePM10 particulate filter is similar to that of a standard particulate-only pre filter, so the overall pressure drop of the system is not increased.

In some ventilation systems like small MVHR units, it is not possible to provide the full range of filtration options that are available in full or half sized filters typically used in AHUs. In this instance, electronic air cleaners become the best option.

Photocatalytic oxidation (PCO) systems utilize a UV light shining on a titanium dioxide catalyst. These can be fitted in the air discharge of an AHU or MVHR to break-down benzene and other volatile organic compounds in the supply air.

Bipolar ionization (BPI) systems can be fitted into the supply air discharge. These systems give opposing electrical charges to any particles that have passed through the filters. These ultrafine particles then form clusters of larger particles that either drop out of the breathing zone or are captured in the low grade filters fitted to fan coils or air conditioning systems. Both PCO and BPI systems create negligible additional pressure drop, and use very little electrical power. It is important that specified electronic air cleaning devices carry the UL 2998 ozone free certification.