Comberton Village College is a large secondary school six miles to the west of Cambridge

Comberton Village College provides a glimpse into a low carbon future for schools. It shows how retrofitting renewable energy technology to an existing school can help educational institutions across the country decarbonise their heating systems.

In its first year of operation, the £3.1m scheme is expected to signifcantly reduce the college’s heating bill and cut carbon emissions by 70%, saving 248 tonnes of CO2. By 2050, with the further decarbonisation of the electrical Grid, that figure is predicted to increase to more than 90%.

Comberton Village College is a large secondary school located close to the city of Cambridge. It is formed from a diverse collection of buildings of various ages, most of which have been constructed as self-contained units, complete with their own plantrooms. The campus has no gas supply, so the majority of buildings were heated by fuel oil, with a few heated using liquefied petroleum gas (LPG).

Bouygues Energies & Services (E&S) is a contractor under the Greater London Authority and Partnership’s energy performance contracting initiative Re:fit. As part of this, in 2018 it was approached by Cambridgeshire County Council and the Cam Academy Trust to develop proposals to decarbonise Comberton Village College.

Bouygues E&S’ senior project manager Ornella Sangermano, and Colin Marchant, site manager – clerk of works

Bouygues E&S energy design manager Tom McGrath describes the process: ‘We start each project by developing an energy baseline that provides us with an overview of the current energy consumption and carbon emissions of the site.

‘We then review potential decarbonisation options and quantify the impact of these for carbon and cost. The most effective options are then presented in a business case that demonstrates that the intervention will save X tonnes of carbon and energy annually, and will offer a financial payback of Y years.’

The metrics form the basis of an energy performance contract (EPC), in which Bouygues E&S guarantees that it will be achieved, says McGrath. ‘We undertake responsibility for full design, planning and procurement, and include this in our investment-grade proposal, and this provides a significant amount of security to the client,’ he adds.

Bouygues E&S had to assess whether the reduced system temperature would render the existing radiators and fan convector units undersized

Bouygues E&S was given a blank slate by Cambridgeshire County Council and the Trust, and its proposals included an option to upgrade the college’s existing lighting installation to an LED-based solution, which would go some way to reducing its electricity consumption. It also included: the installation of photovoltaic (PV) panels on the roofs of some of the buildings, to help meet a proportion of the college’s electrical demand from renewable sources; the addition of insulation to some of the heating circuits; and improvements to the building management system (BMS), to enable it to operate more efficiently.

The proposal also addressed the legacy of the college’s ad hoc expansion over the years, which meant virtually every building on the campus had its own plantroom, many of which housed oil-fired boilers that were at the end of life and in need of replacing.

As part of its initial assessment, Bouygues looked at like-for-like replacement of the various oil-fired and LPG-fired boilers with individual air source heat pumps (ASHPs). However, McGrath says it soon became apparent that this was unworkable for most buildings because of a lack of suitable external space and noise constraints for the heat

pump condensers.

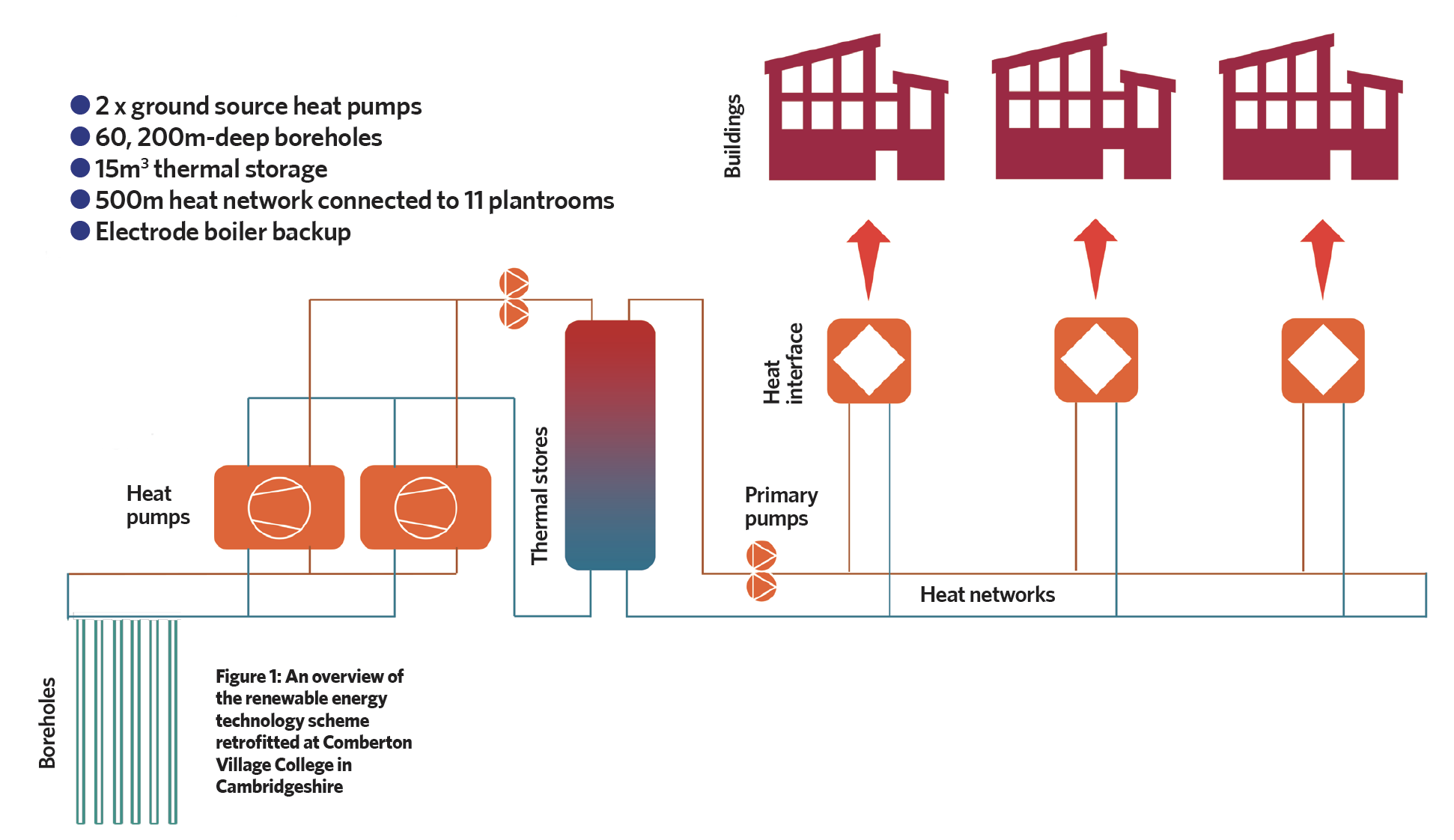

Heat is pumped from the thermal store to 11 plantrooms

Instead, Bouygues E&S came up with a more radical proposal of combining all the satellite plant into a single, centralised system. This also had the benefit of removing the college’s reliance on oil heating. ‘The big-ticket item was that we saw an opportunity to decarbonise the college’s heating significantly by installing a large-scale heat network using centralised plant,’ says McGrath.

The decarbonisation programme started in 2019. Initially, what McGrath calls ‘the more straightforward elements’ were undertaken – replacing the lighting and the installation of 140kWp of PVs. ‘As soon as the college saw the impact of these interventions on its carbon footprint, its ambitions grew and we were tasked with further developing the heat network proposal,’ says McGrath.

The starting point for developing the detailed design for the heat network was to make an assessment of the college’s peak heat demand. ‘All we had to go on was the number of boilers, some of which had known operating efficiencies, and incomplete sets of fuel oil and LPG delivery notes,’ says McGrath.

To try to quantify the peak heat demand, external consultants were employed to undertake a heat loss assessment for each of the college’s buildings. By combining this information and the fuel consumption data, a notional peak demand of 705kW was estimated. However, when it came to sizing the system, because of the uncertainty about the accuracy of the peak heating, and to increase the system resilience, the system was sized based on two 500kW Carrier ground source heat pumps (GSHPs), providing a total peak output of 1,000kW.

The two 500kW ground source heat pumps

These deliver heat at 65oC to a 15m3 buffer tank that smooths out the fluctuation in demand and allows the heat pumps to operate at their optimum setpoint. Hot water is then pumped from the thermal store around the campus to 11 individual plantrooms through insulated pipes, which are either buried or attached to buildings.

As an additional contingency, an electrode boiler has been installed, which has the capacity to meet the peak demand and can provide top-up heat as and when required, such as if a heat pump is out of service.

The heat pumps draw heat from ground loops contained in 60 boreholes, each 200m deep, located beneath three of the college’s car parks: 30 boreholes in one, 18 in another, and 12 in another. The boreholes are spaced at one per 9m2.

‘One of the biggest challenges was installing boreholes on a live site where parking is at a premium,’ says McGrath. ‘To mitigate this, we spread them over the various car parks and phased the installation to minimise disruption to parking. This was a real success for the project and wouldn’t have been possible without the close relationships developed between the client, design team and project managers.’

Bouygues E&S did consider air source instead of ground source, but the same issues of a lack of space and concern about noise from the condenser fans made this impractical. It also considered other heating options, including biomass and direct electric, which would decarbonise the college over time as the Grid decarbonises. ‘If you want heating costs comparable with those of gas, then you need to use heat pumps,’ says McGrath.

To maximise the operating efficiency of the GSHPs, the heat network is designed to operate at a system temperature of 65oC flow, 55oC return, which is lower than the existing heating. At these temperatures the heat pumps are expected to operate with a coefficient of performance (COP) of approximately 2.7.

New pipework installed for the heat network

Bouygues E&S had to assess whether the reduced system temperature would render the college’s existing radiators and fan convector units undersized for the space. McGrath says heat loss assessment data showed that it was primarily the fan convector units that would have to be replaced because, at the lower circuit temperature, their output dropped to the point where it was insufficient to meet the heat demand. ‘Generally speaking, 70% of the emitters are able to cope with the reduced temperature, so only about 30% of emitters needed to be upgraded,’ he says.

Improvements to the thermal performance of the building fabric was outside the scope of the project. Instead, fabric improvements will be carried out ‘as and when each building is refurbished’, says McGrath, which will reduce the amount of energy needed by each building over time.

‘What we have said to the school is: “You’ve currently got a boiler supplying, say, 100kW of heat to a building, so – under the decarbonisation scheme – we’re going to install a plate heat exchanger that will deliver an equivalent heat output,’ he explains.

‘As the buildings are refurbished, this will provide the opportunity to improve the thermal performance of the fabric, which, in turn, should allow the supply temperature to drop and further improve the efficiency of the heat pumps’.

An incidental benefit of replacing the large, ageing fossil fuel-fired boilers with much smaller heat exchangers is that the project has improved maintenance access significantly.

Heat from the GSHPs is delivered at 65°C to a 15m3 thermal store

Currently, the system is designed to operate year-round at 65°C, while there is no space heating demand in summer, there is a swimming pool, and the system supplies hot water to calorifiers throughout the site.

As a result the domestic hot water temperature needs to remain above 60°C to manage the domestic hot water quality

‘In theory, we could lower the temperature on the heat network significantly during summer, to give us additional heat pump efficiency improvements, but we’re restricted because of the hot water demand,’ McGrath says. ‘The intention in the future, as the calorifiers are replaced, is that we will be able to drop the system flow temperature to 45°C in summer, and use this to preheat the hot water, and then use electric immersion heaters in the hot water cylinders to top up the water temperatures.’

It will be a showcase for retrofitting renewable energy technologies and heat network installations to deliver long-term carbon emissions reductions

Altering the system flow temperature in summer is the only major change planned. Although the capacity of the heating system can, in principle, be expanded incrementally later to supply other heat demands, constraints on plantroom space and space for new boreholes mean there is no capacity to extend the scheme beyond the college boundaries – to serve local residents, for example.

However, Cambridgeshire County Council, again working with Bouygues E&S, has built a low carbon heat network at nearby Swaffham Prior (see CIBSE Journal February 2022), which it may look to reproduce elsewhere in the county.

The project involved installing 140kWp of PVs on the roofs

The heat decarbonisation project at Comberton Village College started in October 2021 and the heat network has been running since January – although the scheme has not yet reached practical completion.

‘One of the things we have had to make clear to the college is the importance of the operational strategy,’ says McGrath. ‘At the end of the year, when we do the energy reconciliation, if the scheme is using more energy than we anticipated we need to be able to understand whether this is related to design or an intervention from the college’s facilities management team.’

Funding the decarbonisation of heat

‘The only way a decarbonisation scheme like this could work financially is if there is funding available to support the capital cost of the work,’ says Tom McGrath, energy design manager at Bouygues E&S UK.

The Comberton Village College project has been funded by a £1.9m government grant from Phase 2 of the Public Sector Decarbonisation Scheme (delivered by Salix Finance) and a £1.2m investment from Cambridgeshire County Council.

The Cam Academy Trust, of which Comberton Village College is a member, has entered into a ‘managed services agreement’ with Cambridgeshire County Council to fund plant not covered by grant funding. This arrangement allows the council to recover its capital investment while still delivering a net operational saving to the trust.

For its part, Bouygues has to deliver an ‘investment-grade proposal’. This defines what the design and build contractor is going to deliver, and at what cost, and puts a figure on how much energy the scheme is expected to consume in use.

Energy consumption will be monitored annually. There is a yearly reconciliation based on measuring and verifying the actual performance of the system. If the performance is within an acceptable variance, everyone is happy. If the scheme uses more energy than it is supposed to use, Bouygues is responsible for funding the overspend – then this is either banked to cover any overspends, or used to pay back the project earlier.

‘We’re confident the project will deliver as expected, but with the guarantee, it de-risks the project for the client because, if it doesn’t deliver what we said it would, then Bouygues will pick up the shortfall,’ says McGrath.

The pioneering project is expected to become a showcase for retrofitting renewable energy technologies and heat network installations to deliver significant long-term carbon emissions reductions and future life-cycle costs.

While projects such as Comberton are novel now, they are set to become the new norm as colleges and local authorities continue to move away from fossil-fuelled combustion to heat their buildings