Eco Flex lights feature in a case study on the Grand Hyatt Kuwait hotel

The conversation around sustainability, embodied carbon and the circular economy has accelerated rapidly. Not long ago, it was commonplace for specifiers of lighting equipment to recommend luminaires with halogen or metal halide light sources, and fluorescent lamps were only banned from sale in the UK and Europe this year.

The lighting industry is in a different, healthier place now, and has been leading the conversation on the circular economy with the release of two timely CIBSE guides: TM66: Creating a circular economy in the lighting industry, published in 2021, and TM65.2 – Embodied carbon in building services: lighting, which came out last month.

The original TM65 – Embodied carbon in building services (aka ‘the parent’ document) and accompanying carbon calculator is already a widely accepted methodology for calculating C02e in build services equipment. It does so without having to submit products for full Life Cycle Assessments (LCAs), a process that is lengthy and expensive.

The TM65 methodology offers a route to evaluating and understanding the amount of embodied carbon within materials that make up products. It can even be used as a tool for development during the product design phase because of the process’s fast turn-around.

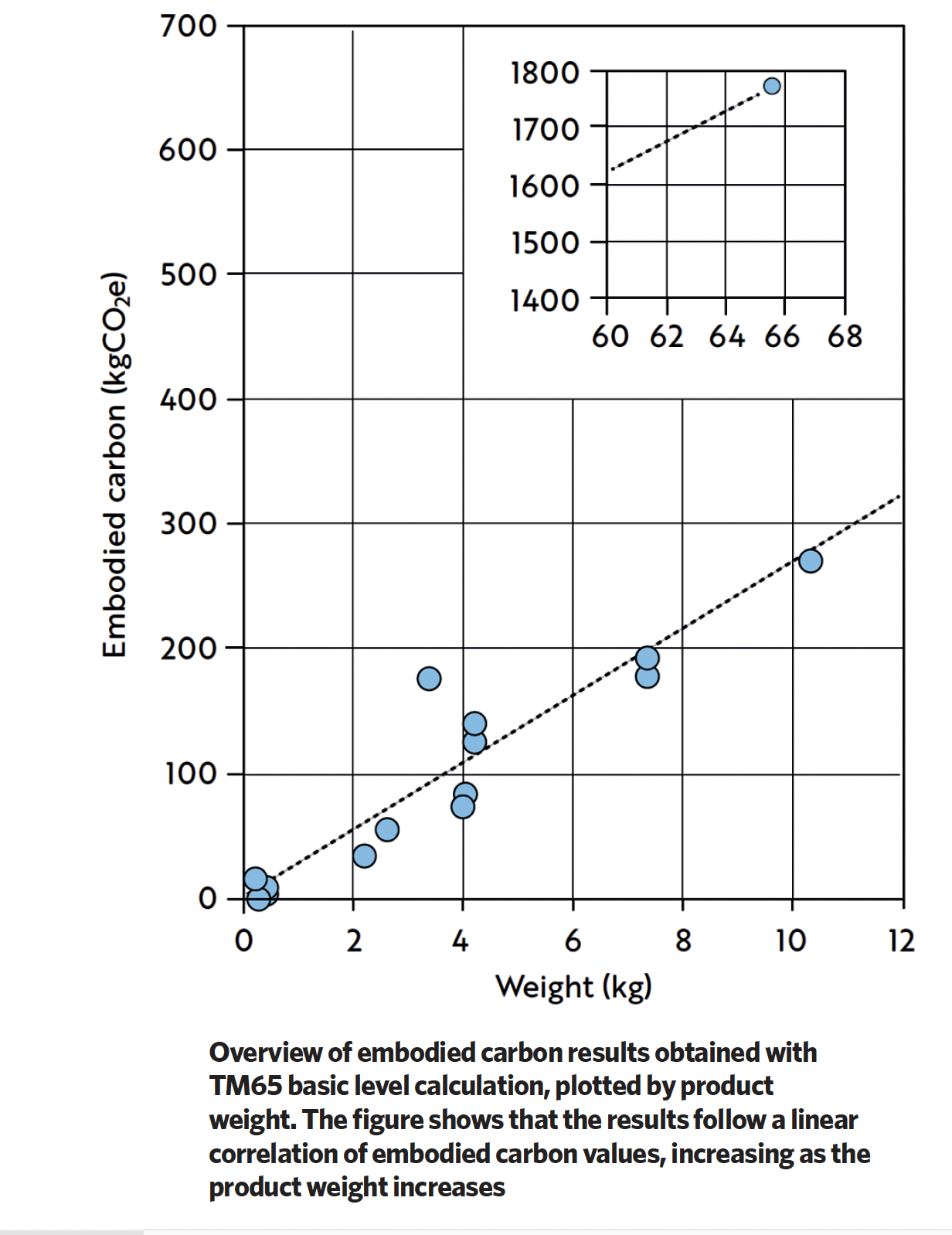

Lighting manufacturers have been very responsive to industry demands for this data and the 18 case studies within TM65.2 demonstrate this. The methodology enables material data, including manufacturing process data, to put a C02e value on lighting equipment. The more data that becomes available the more ‘environmentally aware’ the decisions that lighting designers and specifiers can make for projects.

Why a lighting version of TM65?

Manufacturers of lighting equipment were so keen to calculate the embodied carbon in their products that they were using the ‘parent document’ and the earlier version of the carbon calculator. Although this was a good place to start, it showed that the process was not created for this purpose.

As a result, lighting equipment was showing higher values of C02e than it actually had as some materials used in lighting equipment were not in the tool. This could lead to similar materials being used that weren’t similar at all in reality, but are used as a substitute for the calculation.

We are finding that the results of assessments using the TM65.2 approach are closer to that found using a LCA.

The inclusion of more material coefficients will allow for a higher level of accuracy in the embodied carbon values

There is no difference in the ‘core’ TM65 methodology in the new document – it simply makes the calculation process easier and clearer for the lighting industry. To achieve this, two things happened: less importance was given to some generic features that characterise the built environment (such as information on refrigerant charge and leakage), while features that are more relevant to the impact associated with lighting products were highlighted and made clearer for the users.

Changes to the carbon calculator

TM65.2 includes more comprehensive guidelines on using the calculation to better capture the complexity of lighting products, while keeping the simplicity of the TM65 approach. This was possible thanks to the involvement of several lighting manufacturers, who shared information on the material content of their products and allowed the authors to build a list of new embodied carbon coefficients to be added to the TM65 database.

However, because of data availability, it was not always possible to find exact matches for material coefficients. To solve this, guidelines on what to do with components and materials that are not included in the TM65 database were added, such as indications on how to choose alternative materials from the database.

One of the new database additions of TM65.2 relates to the embodied carbon coefficients for aluminium from 100% recycled and 100% virgin sources: these have been added to the aluminium coefficients already in the database, and there are indications on how to account for materials that have intermediate recycled aluminium content. Another important feature is the inclusion of clear indications of what is needed in the calculation to represent a luminaire, and guidelines on how to account for external/integral light sources and control gear, and other auxiliary components.

Meaningful comparisons

The inclusion of more specific rules regarding the calculation of embodied carbon in luminaires allows for a higher level of consistency among products made by different manufacturers. This gives more meaningful comparisons and a higher degree of harmonisation in the industry.

One of the aims is to make sure the methodology can be applied in a consistent way, with less room for subjective choices by those doing the calculation. Additionally, the inclusion of more material coefficients will allow for a higher level of accuracy in the embodied carbon values. It will enable the selection of personalised recycled aluminium content, which will lower the embodied carbon of products and reflect the sustainability efforts of the industry.

Who should use TM65.2?

The document is suitable for all who would like to learn about embodied carbon in lighting equipment, including lighting designers who would like to understand the impact of a product, or manufacturers seeking to evaluate the carbon performance of their existing ranges.

It features a decision tree to show who should use the tool at each stage – for example, if a lighting designer would like to incorporate products with low C02e, they might instigate the calculation assessment, but the next step is for the manufacturer to gather the data for the materials, processes and locations that are required for the assessment. The designer won’t have access to all this data without the manufacturer’s involvement.

Plans for future versions are touched on within the document. As more reliable material data becomes available, we would like to add it to the carbon calculator so that lighting equipment can be well represented and calculated as fully as possible. Of course, the purpose of this document is to enable faster calculation of C02e in lighting equipment and not to replicate or replace a full LCA.

We believe TM65.2 will attract more users to the TM65 methodology because of the improved accuracy. Lighting manufacturers will be able to carry out the calculation with clearer guidance and rules, and will see embodied carbon results that better capture their sustainability efforts. Lighting designers and specifiers will be able to advise their clients knowing that the embodied carbon of products was calculated following robust guidelines and, as a consequence, they can more accurately compare products based on their embodied carbon values.

- Kristina Allison MSLL MCIBSE is project lead for TM65.2 and senior lighting designer at Atkins Global; Dr Irene Mazzei is a TM65.2 co-author and KTP Associate Stoane Lighting/Edinburgh Napier University. The two other authors of TM65.2 are: technical lead Jonathan Rush, director at Hoare Lea Lighting, and Simon Fisher, director at F Mark