Pressure independent thermostatic radiator valves (PITRVs) started to appear on the market about 10 years ago, driven by a desire to hydronically balance domestic heating systems more effectively and quickly. A growing number of manufacturers and suppliers have introduced PITRVs into the UK, including Drayton’s auto-balancing TRVs, Danfoss’s dynamic valves, Inatec’s PITRVs, and Giacomini’s DB-PITRVs. They are available in a range of specifications suitable for different applications of hydronic heating systems and types of radiator set-up.

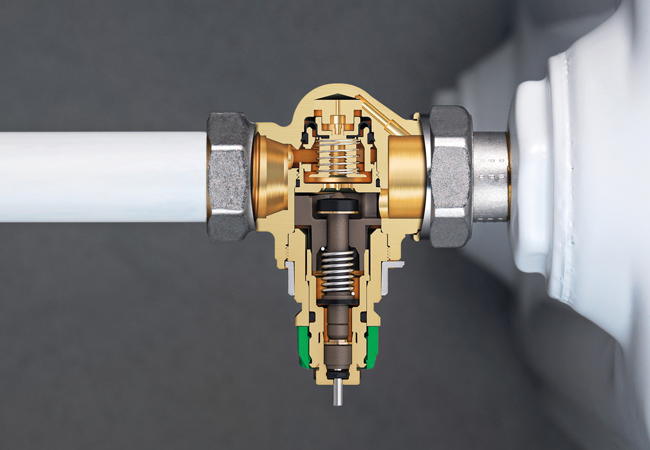

PITRVs are the evolution of thermostatic radiator valves (TRVs), which were developed more than 80 years ago. As well as offering self-regulating temperature control in a heating system, PITRVs effectively incorporate the differential pressure controller of a pressure independent control valve (PICV) into the body of a TRV package.

In this configuration, PITRVs allow the thermostatic control valve to work more consistently as the conditions vary in the heating system, enabling the system to remain balanced as other valves modulate open and closed, and pressure fluctuates.

‘Pressure independent valves for commercial systems have been around for some time, but it has taken a while for the technology to be adapted for TRVs,’ explains Merlin Milner, product owner at domestic heating manufacturer and supplier Drayton. ‘There is greater focus on boilers achieving the best possible coefficient of performance [CoP] by reducing the return temperature back to the boiler for efficient flue gas condensing.’

Set up correctly, PITRVs can reduce energy use significantly compared with more traditional set-ups

By combining three key functions – flow control, temperature control and differential pressure regulation – PITRVs offer a number of advantages over regular TRVs. They are quicker and easier to set up than a standard TRV during system commissioning. As Milner notes: ‘The engineer just needs to know the design heat output of the emitter [radiator or radiant panel] and the target flow temperature. They can then adjust the PITRV to the correct setting, safe in the knowledge that the required flowrate will be achieved, regardless of variations in pressure drop across different parts of the heating circuit.

‘In comparison, the traditional approach of trying to balance a system with a lockshield valve (LSV) is virtually impossible, as many are not designed for this.’ Many LSVs have very poor valve authority, so they need to be almost completely closed before they make any significant change in the water flowrate. This makes system balancing particularly challenging as just a single turn on many hand-operated LSV can go from no flow to maximum flow.

Set up correctly, PITRVs can help maintain the design efficiency of the system, reducing energy use significantly compared with more traditional set-ups. They are suitable for a variety of heating applications and can be integrated into new or existing systems.

Calculating flow rate

The formula for flowrate is represented by:

The volume flowrate, L·s-1, required through a radiator = φ /(cpxΔθ) (assumes the density of water is ≈ 1000 kg.m-3) where φ is the required radiator heat emission (kW), cp is the specific heat capacity of water (kJ·kg–1·K–1 ), and Δθ (often shown as Δt) is the flow/return temperature difference (K).

Cp for water is approximately 4.2 kJ·kg–1·K–1, and the industry standard radiator Δθ is 20K, so this is typically simplified as radiator flow rate (L·s-1) = heat output (kW) / 84

The radiator heat output will be influenced by the flow temperature of the heating water entering the radiator, the water flowrate, and the resulting radiator mean water temperature. When the flowrate is set on a PITRV the required flowrate will be dependent on the actual flow temperature of the heating system and potentially not the manufacturer’s standard system flow temperature/radiator heat output figures. The radiator manufacturer will be able to provide performance data at different water temperatures and desired room temperatures.

The need for balance

Typically, a boiler-based heating system will include a number of radiators in different rooms around the property, usually varying in size to accommodate the output requirements of each room, with different lengths of pipework feeding them from the flow and return to the boiler. That means variances of flow for each radiator within the heating system. Radiators closest to the boiler tend to have less resistance to flow than ones further away, so balancing the system is intended to even this out. Balancing requires some restriction of the flow to the radiators through valves, whether a manual LSV or TRV.

For the heating system to run at optimum efficiency, most boiler manufacturers recommend that the differential temperature – the difference between the flow temperature of the water leaving the boiler and the return temperature of the water coming back – of 20K. Balancing the system aims to ensure that all the radiators on the heating system get sufficient hot water to deliver the required heat output, and that – as the heating water leaves the boiler and approaches any particular radiator, there is no greater or lesser resistance to the flow going through the radiator or carrying on to fulfil the heating requirements of radiators further downstream (or upstream).

In an unbalanced system, insufficient heating water will be delivered to some radiators – particularly those towards the end of the circuit or on upper floors – so they will not produce the heat required. It is likely to mean the return flow temperature is higher, which can reduce, or even negate condensation in the boiler flue gas, greatly reducing efficiency.

PITRVs can be pre-set to maintain a fixed flowrate into each radiator, regardless of changes to the pressure of the system – such as when operating under partial load conditions. Instead of setting a fixed aperture size, as with a LSV, they have an active element inside the differential pressure controller that adjusts automatically to maintain the constant pre-set flowrate. If the radiator output is known, the flowrate can be set by the installer with reference to the manufacturer’s guidance. Flowrate settings are typically between 10 and 135 litres per hour, with a variety of maximum differential pressure options available to suit a range of system set-ups (from 60kPa up to 150kPa, depending on the manufacturer).

Danfoss’s Dynamic Valve fitted to a radiator

Standard practice

The time-saving benefits and efficacy of PITRVs are boosting demand for the products, says Milner. ‘Specifiers are appreciating shorter system servicing because the automatic balancing negates regular manual balancing,’ he adds.

PITRVs may not be appropriate for some types of heating system; Milner explains that systems with a small flow/return temperature difference – such as heat pump circuit that typically require 5K – are likely to require a valve to be selected with a higher Kv [flow coefficient] – heat pumps require a minimum flow to maintain good performance. However, some PITRVs are available with higher flow rates. (Kv is the flowrate of fluid (m3·h-1) through the valve when the pressure drop across the valve is 1 bar (100kPa) – the strange units being so that it numerically matches the imperial Cv).

Milner notes the importance of correct set-up and maintenance to optimise PITRV-equipped heating systems. Before commissioning, the system should be cleaned and flushed of debris, and treated with corrosion inhibitor to ensure the PH levels are correct and to prevent corrosion. ‘The smaller flow apertures of PITRVs mean system cleanliness is more important,’ he adds. ‘While the valves usually have a commissioning position for filling and draining during set-up, special consideration is required for power flushing. ‘Power flushing must take place with the valves or valve inserts removed, or before fitting them. A special tool is available on some manufacturers’ valves to aid power flushing by temporarily removing the valve insert.’

Milner believes PITRVs will soon become a standard option for domestic heating systems ‘when installers begin to understand that the extra cost of the valves is saved many times over by the ease of installation and time saved during commissioning’. Elimination of cold spots around properties and system noise will also reduce the level of call-backs for engineers.

Importantly, stricter rules on energy efficiency are likely to feed back into Building Regulations and encourage more energy efficient valve specification in future.