Minewater is an underused resource that holds significant potential as an energy source and storage solution, with a single mine potentially heating 1,800 buildings. This innovative approach harnesses abandoned mines, with a geothermal solution that can be integrated into smart cooling and heating networks.

Minewater stands ready to serve as a thermal storage powerhouse, accommodating inter-seasonal demand fluctuations. This year, my case study presentation was awarded the ‘Most significant contribution to the art and science of building services engineering’ at the annual CIBSE ASHRAE Technical Symposium. My research expands on a previous feasibility study conducted in Barnsley, Yorkshire, as part of the GreenSCIES project, which examined the integration of heat, power and mobility in a smart local energy system. This involved using waste heat from a glass factory.

During the Industrial Revolution, there was a surge in demand for coal, which reached its peak in 1913, when UK coal extraction reached nearly 290 million tonnes per year. As the years progressed, however, the mines became economically unviable and were subsequently closed. Now, we are left with abandoned mines that can be found below 25% of UK buildings. These have the potential to annually provide nearly 2,200TWh, while the annual demand for heat in the UK is 475TWh.

The worked coal seams within the mines still contain void spaces that have become flooded because of natural water flow. Over time, the water in these void spaces has been heated by the geothermal energy of the surrounding rock formations. As a result, the coal seams offer a sustainable geothermal resource that could be used primarily for heating and cooling buildings.

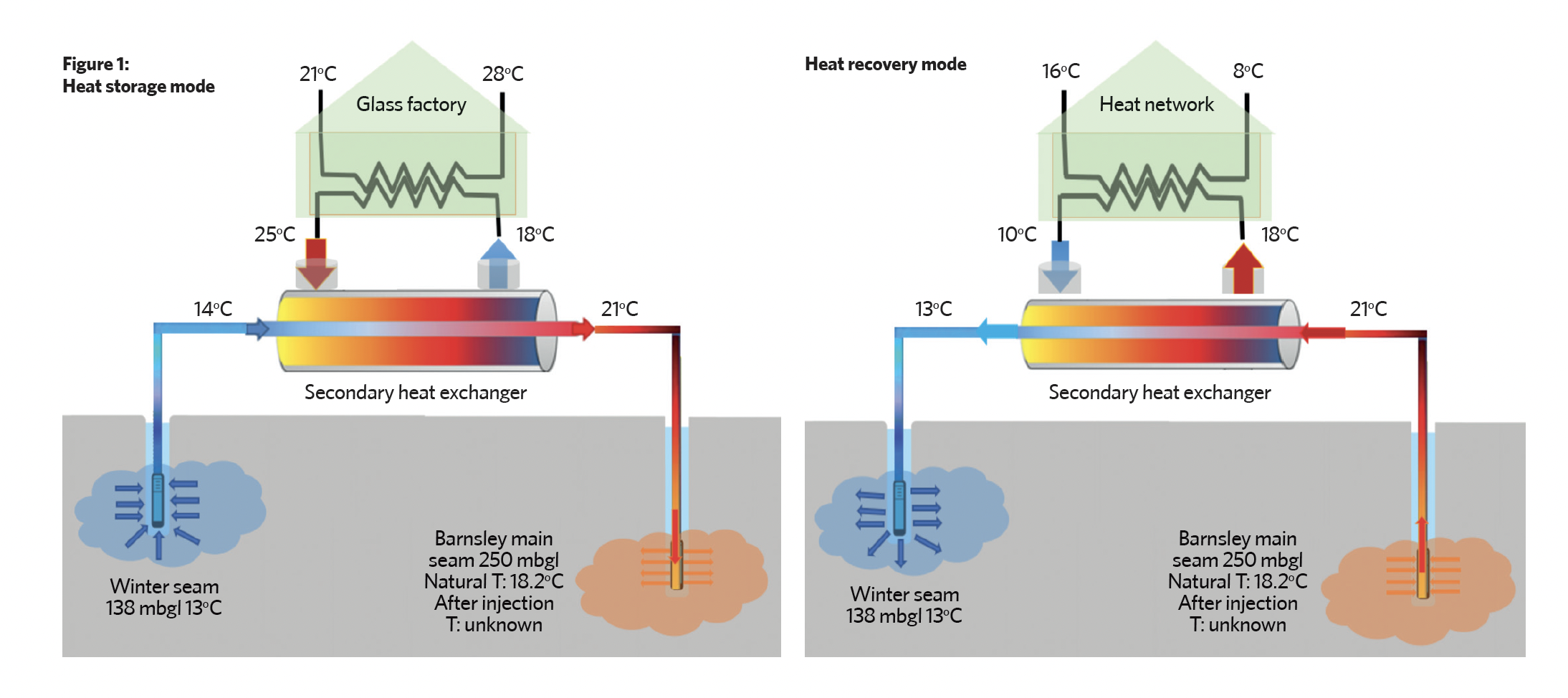

Figure 1 illustrates the heat recovery concept. The subsurface temperature is relatively constant and increases with depth. In heat recovery mode, high-temperature minewater would be pumped and circulated through a heat exchanger. The heat would then be upgraded by a heat pump to an appropriate temperature for distribution via district heating.

During storage mode, low-temperature water from shallow seams is extracted and circulated through a heat exchanger to absorb waste heat. This heat is then stored in a deeper seam with a higher temperature, making it suitable for inter-seasonal usage. In this configuration, cold water can serve the purpose of an industrial cooling system.

A feasibility study considering Barnsley demonstrated that it is possible and financially viable to store up to 7MW of heat from glass manufacturing. This is achieved by using the old mine workings to store and recover heat. However continuously storing 7MW of waste heat requires a substantial flowrate and storage volume of water.

Flooded abandoned mines in the Barnsley area are relatively porous compared with untouched underground formations, which presents an excellent opportunity for a high pumping rate. Data from various sources, including maps, historical records and logs, have been analysed to build a subsurface model primarily focused on void-space assessment.

Data gathering and methodology

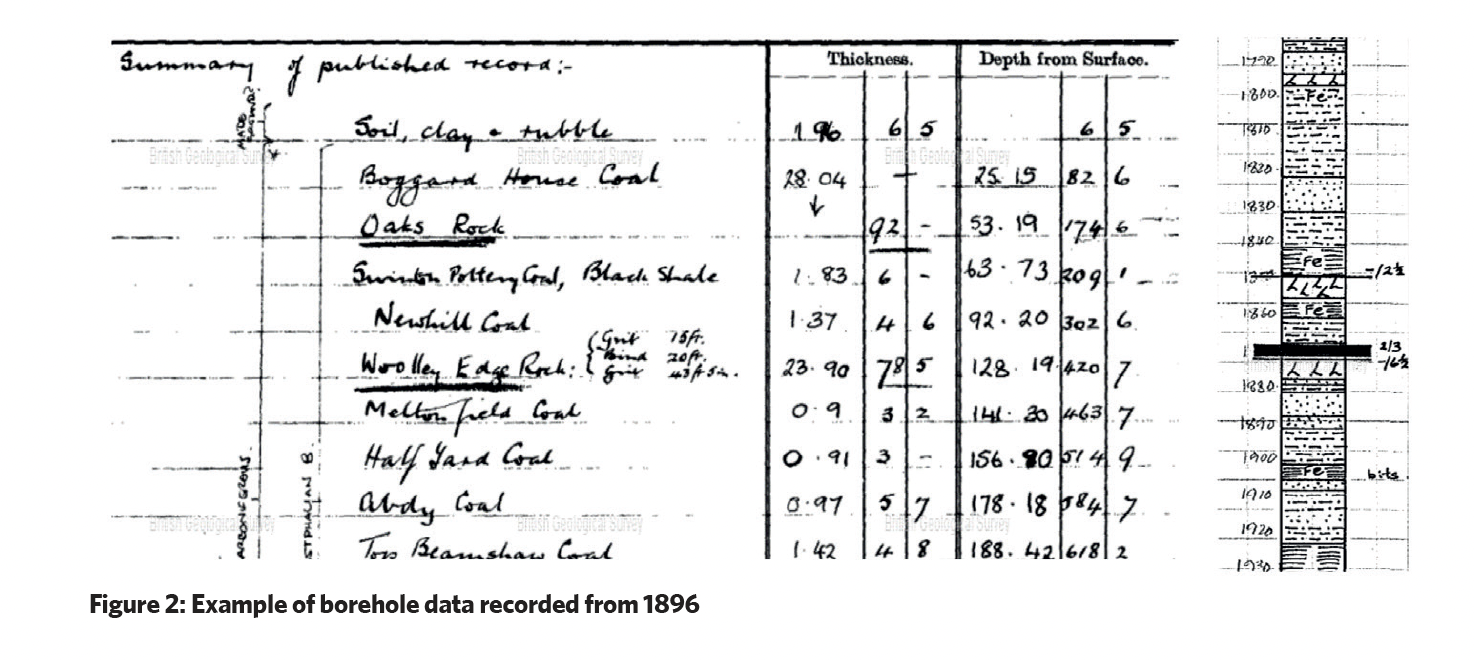

To interpret the subsurface conditions, data was gathered from borehole records, historical maps, and archives. Additionally, scans of mine workings, shaft records, pumping records, and local reports were obtained. These records hold valuable information about the mine’s history and play a crucial role in planning boreholes. Furthermore, some wells monitored by Barnsley Metropolitan Borough Council have recorded water levels, annual temperatures, and other observations. Reports from local authorities have also contributed to the understanding of interconnectivities and flow expectations.

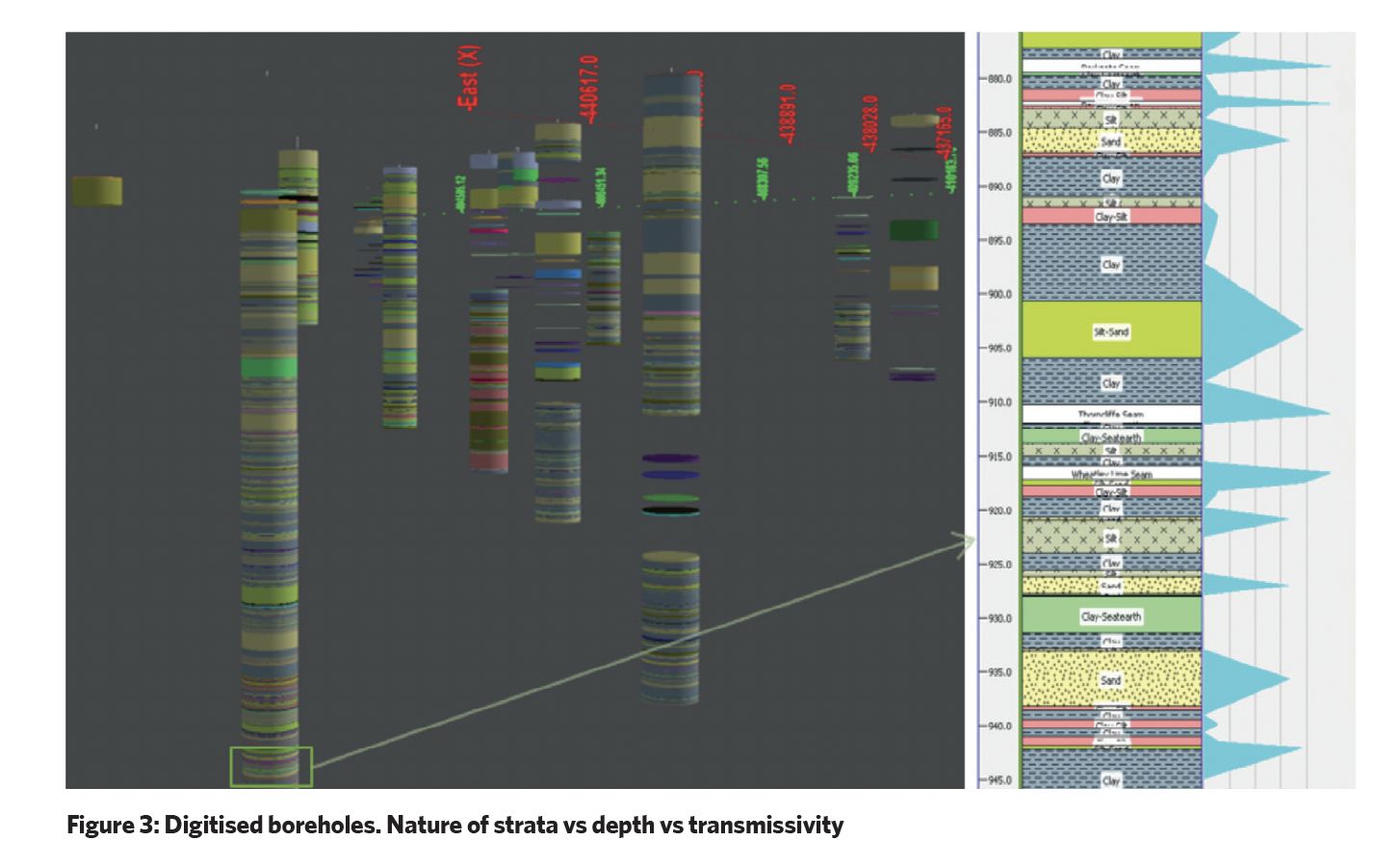

Integrating all these datasets, using specialised software, allows the creation of a data-based model illustrating the subsurface conditions. Initially, ‘BGS Groundhog’ was used to assess the potential of a larger area for the project.

For a more detailed numerical subsurface model and in-depth analysis, we turned to ‘Petrel,’ a widely recognised software application within the fields of petroleum geology and reservoir engineering. This model identifies the most suitable locations for abstraction/injection purposes and establishing quantitative limits on the available void volume for efficient heat storage and recovery.

Figure 2 is an example of a borehole record, showing a typical stratigraphic description and summary log dated from 1896. This information was extracted and along with those for 46 other wells, based on a certain comparable standard, provided the data to visualise the subsurface structure and its properties.

The Barnsley heat storage resource has an average seam thickness of 2.5m and the temperature typically exceeds 18oC. The recorded water level has shown that the shallowest flooded seam beneath the area is the Winter seam, at a depth of 138m. The volumes of the mineworking panels in each seam have been calculated by integrating available data with knowledge of mining techniques, these values have been incorporated into a comprehensive 3D model.

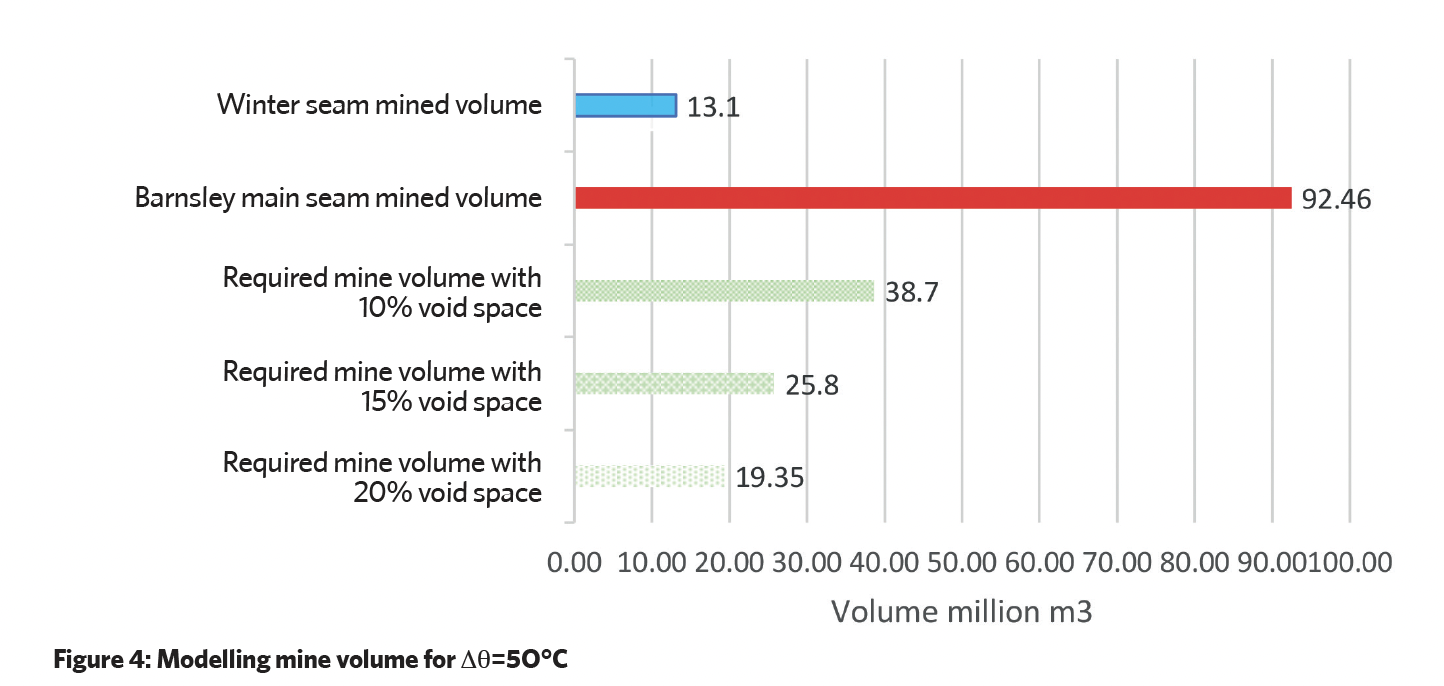

The estimated volume of the mined area in the Winter seam, which serves as the cold source, is approximately 13.1 million.m3, whereas the Barnsley seam has a significantly larger volume of 92.5 million.m3. In heat recovery mode, to achieve the extraction of 5oC of heat during circulation, it is necessary to store around 3.87M.m3 of water in abandoned mines. So, the minimum void volume required to support a 7MW storage system is 3.87 million.

The challenges associated with the application

Despite the abundance of opportunities for the project in Barnsley, several challenges related to data collection, licensing, and the condition of mineworkings must be addressed. Drilling to precise points for injection or abstraction in thin seams poses a considerable challenge. The Winter seam, a source of cold water situated close to the water table, presents a unique concern.

The operation of submerged pumps can cause a rapid drop in the initial water level until it stabilises at the static water level. The difference between these levels is known as drawdown. In the case of the Winter seam, there is a risk of the mine drying up if water is abstracted too aggressively. While extracting water from the shallowest seam may, initially, provide a highly efficient abstraction because of the lower pumping cost, it might not be sustainable in the long term if it depletes the water source.

Estimating the exact void volume in Barnsley’s abandoned mines is challenging. Mines worked after 1949 are anticipated to be collapsed because of high-rate excavation using the longwall technique (where a long wall of coal is extracted in a single continuous operation), while older mines are only partially collapsed. Additionally, roadways and connections may be blocked at certain points. Figure 4 provides an estimate of the required mine volume for a range of likely parameters. It compares the Winter and Barnsley volumes with the required mine volume, ranging from the worst-case scenario to the most probable situation.

The Barnsley seam appears sufficiently large, with workings likely to be connected, and is a strong candidate for providing a warm water source and possible storage. The Winter seam, for balancing the scheme, requires additional volume, which may be met locally by the Beamshaw seam, which is hydraulically connected to the Winter seam, and so doubles the capacity.

A well into the deeper Beamshaw seam offers the advantage that gravity would help draw the water from the Winter to the Beamshaw seam while pumping. The overall system efficiency may drop because of higher pumping costs in deeper seams, but such a scheme could potentially heat 1,800 buildings.

The results obtained will undergo further analysis to quantify the uncertainty ranges associated with this project, significantly reducing the risk of costly test boreholes. Correlating the model results with temperature measurements and flow tests should allow the assessment of the commercial viability of this project and for similar endeavours in Barnsley and beyond.

This effort is important as it assists local authorities in accurately gauging uncertainties around future geothermal energy systems using minewater, a key resource that should be efficiently exploited as the UK transitions to a net zero economy.

Eshagh Goudarzi is a PhD researcher at London South Bank University