The transition from traditional boilers to heat pumps provides an opportunity to improve building thermal performance, increase energy efficiency and reduce carbon emissions. However, successfully replacing boilers with air source heat pumps (ASHPs) involves a detailed and methodical process to ensure optimal performance and deliver energy savings. Based on the experiences of a ‘solutions engineer’, this CPD suggests the early stages that can lead towards a successful transition, focusing on understanding heat usage, measuring and recalculating demands, and experimenting with system options.

The phrase ‘fabric first’ is frequently mooted when discussing ways to improve the environmental performance of buildings. It emphasises designing buildings with appropriate thermal characteristics to increase the opportunity of delivering a building that maintains acceptable, year-round internal conditions with minimal requirements for heating and cooling systems. When discussing renewables – and particularly heat pumps – for existing buildings, ‘fabric first’ typically means enhancing the building envelope to reduce heat losses.

This is crucial, because any heat loss contributes to the total load and, despite the impressive efficiencies of heat pumps, achieving cost-neutral operation compared with gas boilers remains challenging. Reducing heat loss can also lower the required size of heating systems significantly, thereby cutting capital and installation costs associated with the building systems refurbishment.

A key reason heat pumps are closely linked with a ‘fabric first’ approach is because of flow temperatures. ASHPs are more efficient when the source temperature is higher and/or the sink temperature is lower. While the source temperature (ambient temperature) is highly variable in the UK (and not controllable), the sink temperature (flow temperature) can be reduced wherever possible. Lower flow temperatures will reduce the output from emitters that have been designed for higher mean water temperature – so, if less heat is needed because of fabric upgrades, the net result may well be a heating system output that matches the building load.

If the prospect of potentially high costs and unacceptable payback periods, or heritage considerations, prevent changes to the building envelope, a ‘fabric first’ approach may not be feasible, leaving the existing thermal envelope of the building practically unimproved.

For owners of such buildings who wish to decarbonise their heating, a hybrid solution – for example, to maintain the existing gas boilers for peak loads and domestic water generation, and install heat pumps to cover the base load – is often a fast, efficient and affordable approach. However, there is a desire by many owners and operators to skip hybrid solutions and move directly to the full electrification of heat.

High temperature ASHPs (HT ASHPs) have been developed to address this challenge, but the solution is not as straightforward as it seems. Swapping boilers for heat pumps in existing buildings often involves aiming for familiar operation ranges, such as 82/71°C or 80/60°C.

However, achieving an 80°C flow temperature all year round with acceptable efficiencies is optimistic, as even the most advanced R290 (propane) heat pumps are operating at the top end of their performance envelope at 80°C flow. (A high temperature heat pump is classified by BS EN 14825:20221 as delivering 65°C at -7°C dry bulb, -8°C wet-bulb ambient conditions, with the medium and low classifications required to deliver 52°C and 35°C respectively, at the same conditions.)

Even when HT ASHPs can deliver 80°C, this falls slightly short of the 82°C flow required by 82/71°C circuits. Additionally, most heat pumps operate most effectively within a 5K to 10K supply/return temperature differential, making a direct swap into 80/60°C circuits challenging. In any case, boilers in 82/71°C circuits are typically set to operate at a flow temperature of around 85°C to mitigate hydronic inefficiencies, such as temperature dilution.

The challenges involved in the detailed design of replacing boilers with heat pumps should not be underestimated and, before starting a project, significant investigative engineering is recommended. The first stage should be to develop a comprehensive understanding of installed, calculated and actual heat usage.

A familiarisation site visit to meet current operational staff and gather information on the original installation can provide intelligence for later desktop studies, including: determining the original design temperature and loads; hydronic inefficiencies, such as exposed, poorly insulated pipework or temperature dilution; and whether the building has been extended, reduced, zoned or had alternative heating systems installed.

It is important, at this early stage, to ascertain the expectations of the building user/owner around the outcome of the current project, as well as to discover any plans for the coming years that may impact the building’s thermal loads and usage.

The process to ascertain current loads should ideally start early in the heating season, to allow for a full season’s measurement and develop a comprehensive understanding of the building’s heating demands. Detailed sketches and drawings should be created to represent the existing heating generation and distribution systems. Aside from helping to understand the layout, these will be essential for any subsequent nodal analysis.

The sketches may be compared against available onsite schematics or operation and maintenance (O&M) manuals, to identify any interim additions or changes to the system. It is important to understand the operational temperature ranges and frequencies, and the load requirements, for each heating circuit. Existing heat meters or temporary ultrasonic heat meters may be used to gather usage data. This requires at least a transitional and winter season to build enough data for extrapolation, and this can be validated with other calculated data.

Heat demands should be recalculated, particularly if the property has undergone remedial works to the thermal envelope. (Original calculations, if available, may be used for comparison.) For space heating, room-by-room heat loss calculations will provide the load requirement to establish the parameters for the distribution circuits, and will be vital for experimenting with novel flow temperatures.

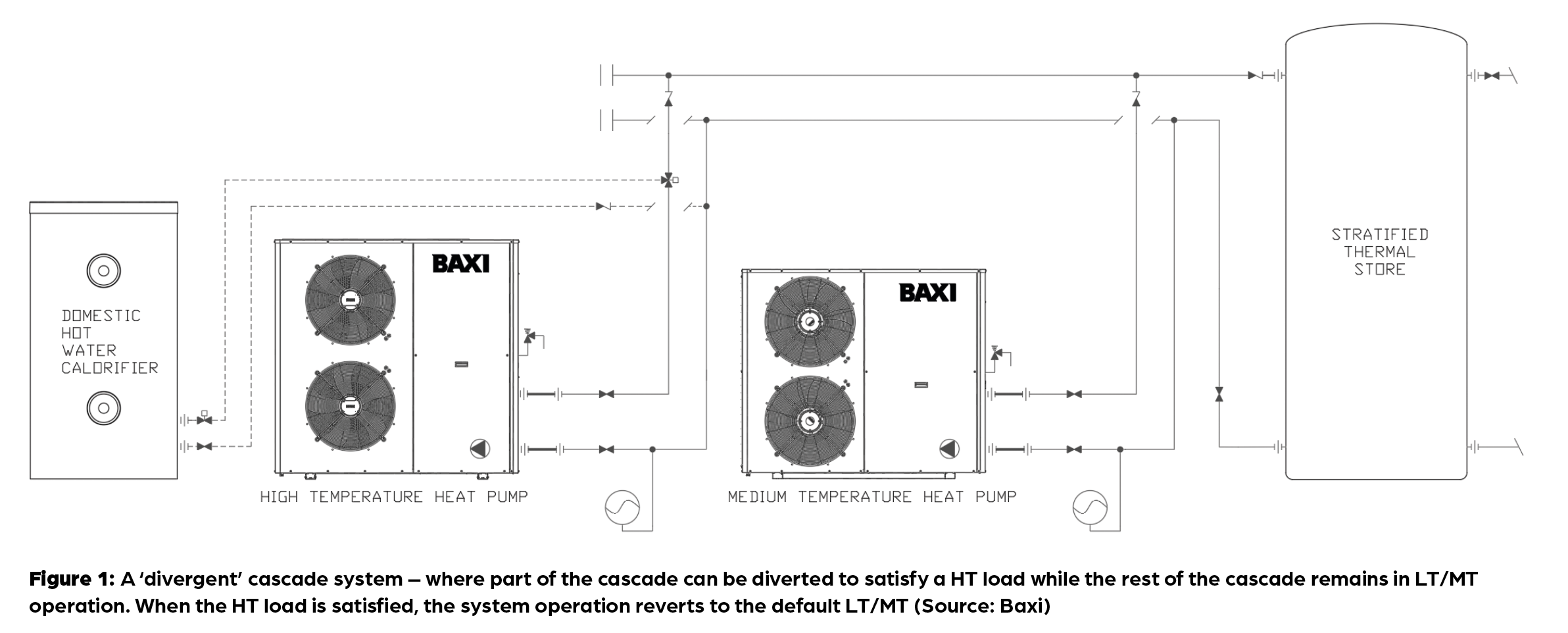

Historic data, such as gas utilisation and building management system (BMS) data, can assist in building a comprehensive picture of current building demands. (Historic meter readings must be treated with caution as, for example, they may include gas used in catering and other processes.) BMS logs can provide invaluable intelligence on variable temperature (VT) circuits and the application of weather compensation curves that can assist in the interpretation of the heating demands.

Experimenting with flow temperatures can reveal new options to decarbonise, reduce capital costs and lower running costs. For most buildings with a setpoint of 21°C, internal emitters do not require flow temperatures of 80°C to 82°C year round.

Reducing flow temperatures during heating months, while carefully monitoring internal comfort temperatures, may yield insightful results. Careful modelling of the building can also provide information for updated emitter requirements and intelligence for optimising weather-compensated flow temperature curves.

After initial investigations and experimentation, it is important to understand the weighting of each circuit in terms of overall demand. The initial step is to assess the peak power demand for each circuit and then establish the usage profile over time to ascertain an overall power profile. This can then be used to inform the determination of the minimum flow temperature that will deliver the required performance using current, or modified, heat emitters.

Circuits should be organised with others that have very similar attributes. For example, a priority VT load operating almost continuously at 55°C should not be grouped with a sporadic constant temperature (CT) load requiring 82°C. In such cases, separating the CT load (sometimes referred to as ‘bracketing’ – see boxout) to be supplied by a heat generator independent of heat pump-supplied circuits may provide greater overall efficiency.

Bracketing

Bracketing is used to organise the system into manageable sections based on known and weighted data. For example, considering a significant CT circuit dedicated solely to an air handling plant. In such a case, the decision might be made to ‘bracket’ this circuit out of the main heating system.

By isolating this circuit and connecting it directly to its own heat pump plant, the heating coils may be adjusted to accommodate a flow temperature of 55°C or lower. This adjustment alone has the potential to boost the heat pump’s efficiency by up to 150%, compared with a design temperature of around 80°C.

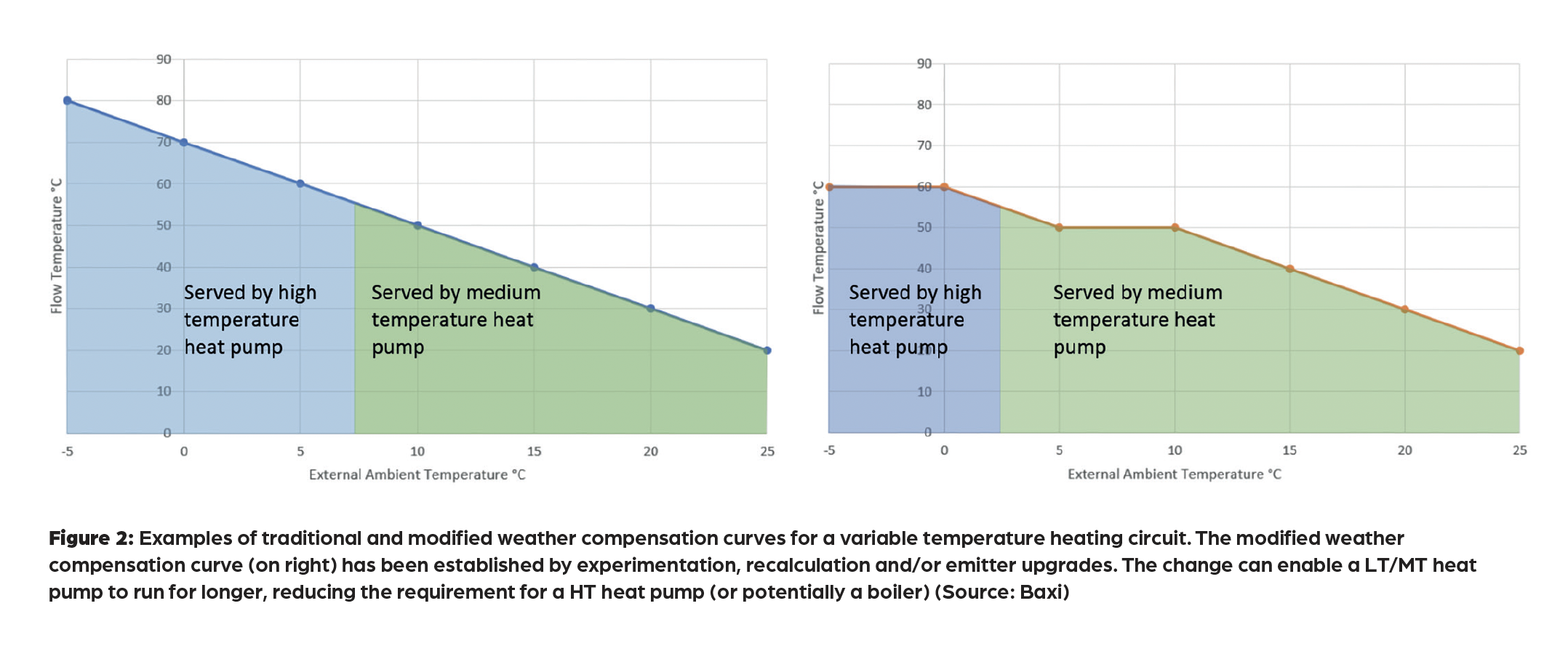

The same concept applies to VT circuits when the CT circuit cannot deviate from its current design flow temperature. Bracketing VT circuits can lead to significant efficiency gains, as weather compensation can be managed directly at the plant without the need for mixing valves. With direct weather compensation on HT ASHPs, the flow temperature can vary between 35°C and 80°C. If it is feasible, heat emitters may be modified to allow for a more aggressive weather-compensated temperature curve, as illustrated in Figure 2. The periods when the HT ASHPs must maintain an 80°C flow can be balanced out in terms of overall efficiency by the times when lower flow temperatures are sufficient.

The weighting aspect of bracketing involves understanding the capacity requirements for each circuit. For instance, if VT circuits account for 80% of the total load, addressing them independently while keeping the CT circuit at an 80°C flow might enhance the building’s overall efficiency without necessitating the replacement of air handling unit (AHU) coils.

Care should be taken, however, when evaluating potential medium/low-temperature circuits. Even if these circuits represent only a small percentage of the overall peak heating demand, they may still contribute significantly to the overall energy usage.

Although CT circuits nominally maintain a constant temperature, it may be possible to reduce flow temperatures while maintaining the required levels of performance and comfort. This can lead to significant energy savings and improved efficiency. Specific needs of high-temperature CT circuits may be addressed by advanced heat pump technologies or hybrid systems that can manage varying temperature requirements efficiently. For example, when the CT is serving loads such as calorifiers, the higher temperatures required may be delivered by employing a ‘divergent’ cascade heat pump system, as shown in Figure 1.

A common application is where an existing building heating system includes gas boilers operating at 82/71°C. For example, a particular existing application has a 300kW CT distribution system and a 100kW VT distribution system, both running at the same boiler flow temperature (the VT system being indirectly weather-compensated).

Cost and operational constraints mean that replacing CT components to reduce the required flow temperature is not feasible. Through experimentation and recalculations, it transpires that the VT distribution circuit can still operate successfully at 55/45°C.

Three solutions might be considered. The first solution involves replacing the gas boilers with high-temperature heat pumps on a kW-for-kW basis, maintaining the 82/71°C requirement year round. This has the advantage of not requiring significant modifications to the existing circuits, making project execution relatively straightforward. However, the capital costs are extremely high, and the high-temperature heat pumps would be operating at the limit of their operating envelope throughout the year.

The second solution divides off the VT circuit and allocates it to medium- or high-temperature heat pumps, while retaining the gas boilers for the CT distribution. This hybrid solution requires less capital outlay and reduces electrical demand. Additionally, lowering the flow temperature broadens the range of heat pump technology options. The downside is that this approach only partially decarbonises the peak load.

The third solution builds on the second by adding a pre-heat tank for domestic hot water (DHW) served by an ASHP. This configuration retains the gas boilers for the CT distribution while allocating the VT circuit to medium or HT ASHPs. The advantages include a reduction in electrical demand, a broader range of heat pump technology options, and a larger portion of the heat being decarbonised. However, this solution also has its drawbacks, such as the need for additional space for a DHW pre-heat tank and more complex controls and valving.

In refurbishment projects, it is crucial to assess whether there is sufficient electrical capacity to support new systems and, if necessary, to evaluate the financial implications of upgrading electrical systems. Exploring potential options, such as integrating photovoltaic (PV) systems, can help offset higher electrical loads.

As building owners and operators explore boiler replacement projects and the various options for decarbonising their heating systems, priority should be given to fabric improvements. Replacing emitters to deliver low-temperature heating generally results in higher overall efficiency compared with employing high-temperature heat pump systems.

Space and noise constraints are often unavoidable, and the ultimate selection of heat pumps will typically require a compromise, but, in any case, a key engineering consideration is to ensure that the heat pumps are not oversized in terms of load.

Achieving perfection in decarbonisation can be difficult when fabric upgrades are limited, but a thorough understanding of the building’s thermal profile helps guide informed decision-making and ensures realistic expectations are set.

© Tim Dwyer 2024.

We thank Ryan Kirkwood of Baxi Solutions for sharing his notes and expertise, which formed the basis of this article.

References:

- BS EN 14825:2022 ‘Air conditioners, liquid chilling packages and heat pumps, with electrically driven compressors, for space heating and cooling, commercial and process cooling. Testing and rating at part load conditions and calculation of seasonal performance, BSI 2022 – under review.