This CPD module considers how natural cooling can utilise phase-change materials (PCMs) both to facilitate ventilation and to reduce the building’s energy use, so lightening its carbon footprint. This application is particularly appropriate in temperate climate zones – such as the UK and northern Europe – where external (ambient) temperatures are typically moderate, with cool night-time temperatures.

The technology behind phase change systems

There are three types of energy storage:

1. Sensible heat storage

2. Latent heat storage

3. Thermochemical energy storage.

In sensible heat storage, energy (or heat) is stored/released by heating/cooling a liquid or solid storage material through heat transfer – a significant change in temperature in the storage medium is required to transfer the heat. Examples of materials typically used as a storage medium are water, air, oil, ground rocks and sand.

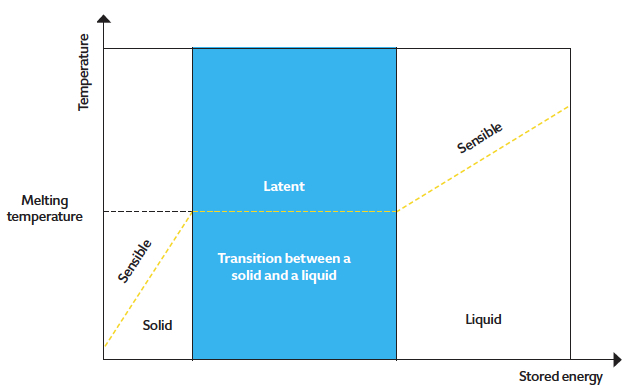

Figure 1: The latent energy provides the principal mechanism for thermal storage in PCMs

Latent heat storage involves the change of a substance from one phase to another at a fixed temperature (the melting temperature, as shown in Figure 1), and is stored during the phase change – for example, melting or crystallisation. The PCMs are usually packed in tubes or plastic capsules, or incorporated into plasterboard or ceiling panels.

Thermochemical energy storage is an emerging method with the potential for high-density use. Energy storage based on chemical reactions is particularly appropriate for long-term storage, such as the seasonal storage of solar heat.3

Natural cooling systems take advantage of the PCM’s reaction to temperature. By melting and solidifying at a known temperature, it is capable of storing or releasing large amounts of energy. This article specifically focuses on latent heat storage that has the advantage of high energy storage density, small temperature swing and a wide variety of

PCMs available.

Organic and inorganic compounds are the two most common groups of PCMs, and there are manufactured PCMs – organic and inorganic – that can meet specific system needs of temperature and energy storage.

Typically, organic PCMs are non-corrosive and chemically stable, and exhibit little or no sub-cooling. Sub-cooling requires lower temperature outdoor air before the PCM solidifies, so is not beneficial. Organic PCMs are compatible with most building materials, and have a high latent heat per unit weight and low vapour pressure. Their disadvantages include low thermal conductivity, high changes in volume on phase change, and potential issues with flammability.

Generally, inorganic compounds have a comparatively high latent heat per unit volume, high thermal conductivity, are non-flammable and are low in cost compared with organic compounds. However, they can be corrosive to some metals and can suffer from decomposition and sub-cooling.

Simple applications of PCM cooling systems

When used as an application for natural cooling, the PCM works across the 24-hour period to keep the room cool, without using active air-conditioning. During the day, as warm air is passed over the PCM, it absorbs sensible heat from the air to turn from a solid to a liquid, thereby cooling the air. Overnight, cool air is passed across the PCM, returning it to its solid state.

There are many applications where PCMs can be applied for heat and cool energy storage in buildings. Natural cooling is a building design approach that attempts to control temperatures in a building with either very low or zero-energy consumption. An example of a very simple form of a passive cooling application uses static PCMs in ceiling or wall tiles to cool a building. In the summer season, cool night air is drawn into the building and used both to lower the room temperature and to store cooling energy in the PCM, for use the following day. While this is a straightforward approach, the building user has no control – it is not possible to manage which areas are cooled or when the stored cooling energy is utilised. It also requires a separate ventilation strategy, as this simple approach only controls temperature and not the ‘indoor air quality’ or the CO2 level.

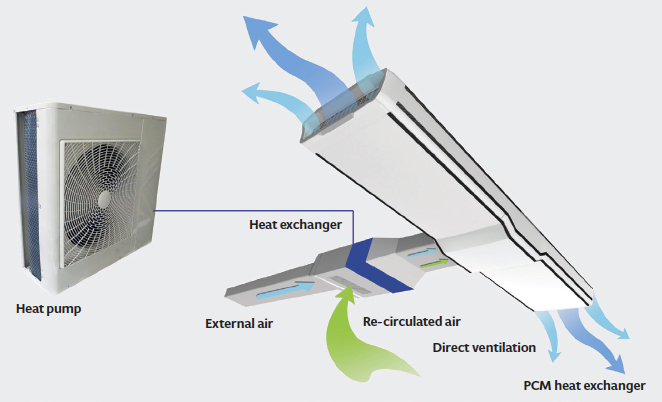

Figure 2: Hybrid PCM cooling system, augmented with an air-sourced reversible heat pump to supply additional ‘top-up’ cooling when internal loads have consumed all the cooling stored from the overnight cool outdoor air (Source: Monodraught)

More advanced natural cooling systems can utilise PCMs to control how much energy is stored and released from the thermal store, and manage where and when this energy is released. So, for example, the benefit of the cooling may be held off until the afternoon, when maximum heat gains are most likely. By removing the need to use a traditional air conditioning system, the building will have no need for the refrigerants that are required for mechanical cooling systems.

In cases where peak loads are less predictable – such as in a teaching space with computers – natural cooling PCM systems can integrate with heat pumps to form hybrid cooling systems, allowing greater capacity while still minimising year-round energy use. Both these systems can also provide full ventilation as well as building-specific CO2 and temperature control. By using PCMs in a natural or hybrid cooling system, building owners and users can reduce their carbon footprint – helping to meet carbon reduction commitments, as well as reducing energy costs. It also allows building owners to satisfy building regulations for ventilation and thermal comfort.

Using a natural or hybrid cooling system will reduce both the peak power and annual energy demand, and can improve the building’s ‘environmental rating’. There are also health benefits for users of the building as, by continuing to furnish high outdoor air supply rates, occupants are likely to feel more alert and maintain higher concentration levels.4 During the daytime, natural cooling systems can monitor indoor and outdoor temperatures, internal CO2 levels and humidity, and modulate the natural ventilation rate accordingly. By improving air quality, the natural cooling solution can improve productivity and attendance – potentially reducing the environmental aspects associated with ‘sick building syndrome’. A recent study in the US also showed that students in schools built using ‘green’ credentials were more likely to be eco-conscious in their everyday lives.5

Hybrid PCM cooling solutions

Commercial applications of hybrid cooling systems (such as that shown in Figure 2) can use night-time cooling to charge dedicated thermal stores that contain PCM. The natural cooling system combines the cooling effect of the PCM with fresh air supplied by an integrated air handling unit to provide ventilation and cooling. This can reduce energy consumption compared with traditional air conditioning, while maintaining thermal conditions that are still appropriate for the space.

The appearance in the room for the PCM system is no different from that of a standard ventilation system

This can be designed to take into account the building’s thermal properties, the local weather conditions, and internal loads such as electrical lighting, equipment and occupancy levels – applying adaptive principles that can allow the controlled energy saving alterations to set-point temperature. For example, when the weather is particularly hot, the system can be set to allow internal temperatures to rise towards the limits of acceptable comfort (typically considered as being 26°C6 in summer for temperate climates). Such systems will always benefit from a night-time recharge of the in-built thermal store during peak summer periods but, in hybrid systems, additional top-up cooling can be applied through the use of the heat pump during the daytime. The integration of active refrigeration will ensure the most appropriate use of the stored cooling, while maintaining control of the indoor temperature.7

PCM natural cooling systems are recognised by BREEAM new construction-non-domestic buildings8, contributing 28 credits across areas such as life-cycle costs, air quality, thermal comfort and low and zero carbon technologies.

Natural cooling case study, utilising PCM to reduce energy use and improve CO2 levels

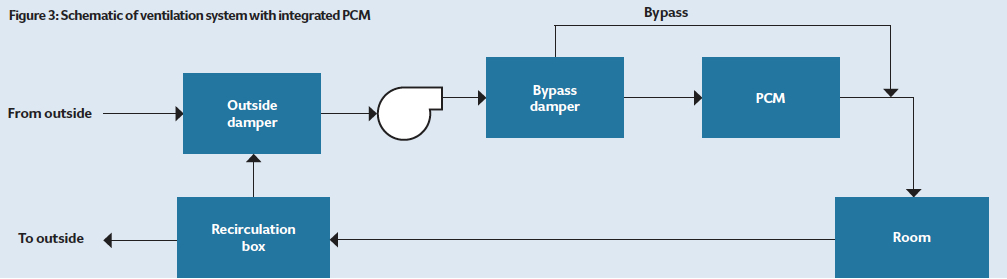

A recent article9 reported on a year-long monitoring programme of a PCM cooling system (with no additional active refrigeration) that was applied and monitored in a university seminar room in south-west England in 2013. The seminar room was chosen because of its use as a computer laboratory, resulting in high internal heat gains. The 117m2 room had one west-facing quarter-glazed external wall, internal blinds and 26 computers inside, with a total internal heat gain9 of 60W·m-2. The room’s ventilation and cooling was provided with an 8kW (cooling)-rated PCM unit (as shown schematically in Figure 3), and heating was supplied by perimeter radiators. The windows were also operable. The system was concealed in the false ceiling, and for building occupants it appeared to be a conventional ventilation system, featuring two air supply terminals and one air extract terminal. Air was drawn from outside the room using a variable-speed fan. During operational hours – and depending on monitored CO2 levels – the air was mixed with recirculated air from the room to conserve energy. The air was then directed through the PCM thermal store, known as a ‘thermal battery’, made up of a battery of PCM plates, where the air passes in the parallel channels between the plates.

The air was cooled if necessary (determined by air temperature sensors and control rules) or bypassed the store if cooling was not needed. Outside occupied hours, outdoor air was used to recharge the PCM thermal battery, with the recharge duration determined by air temperature sensors and control strategy.

The system maintained the room temperature within the range of the upper and lower limits of the Education Funding Agency criteria of between 20°C and 28°C. The CO2 concentration was also monitored for the whole year, with daily average concentration always less than 1,000 ppm, and the 1,500 ppm maximum specified limit was never exceeded. The current, widely regarded standard for good indoor air quality is 1,000 ppm10 for a mechanically ventilated space, and the performance in this installation exceeded the requirements of UK’s Education Funding Authority’s ‘Baseline Designs for Schools’.11

The fan energy used by the system for the year was determined as 0.77kWh·m-2 – which was the energy required to provide the ventilation air as well as the integral cooling. To offer some comparison, CIBSE TM57, Integrated School Design (Table 15) indicates that – based on surveys of electrical energy use in UK secondary schools – those using (traditional) ‘mechanical ventilation’ compared with (traditional) ‘natural ventilation’ annually consumed an additional 6kWh·m-2, far greater than the 0.77kWh·m-2 of this particular system. (CIBSE TM57 also presents case studies of good quality natural ventilation systems that require an annual cooling energy of 3.5kWh·m-2. This, again, indicates that the PCM system may deliver a very favourable energy performance.)

While traditional air conditioning systems are likely to offer more accurate temperature (and humidity) control, PCM-based natural cooling and ventilation can be beneficial through reducing energy consumption while supplying ventilation air for a building. Case studies7 – including the one referred to in this article – have shown that energy costs of such systems can be relatively low, while CO2 and temperature levels are also kept within the required limits.

© Tim Dwyer, 2016.

- With thanks to Ruth Buckingham for her core contributions to this article.

References:

- Paris agreement – accessed 4 June 2016.

- Better spaces for learning, RIBA, May 2016.

- Abedin, A. et al, A Critical Review of Thermochemical Energy Storage Systems, The Open Renewable Energy Journal, 2011.

- Fresh air improves performance of children in schools – accessed 4 June 2016.

- An unexpected benefit of green buildings? More conscientious kids – accessed 4 June 2016.

- CIBSE Guide A Environmental criteria for design, Table 1.7, CIBSE 2015.

- Cool-Phase Hybrid literature – accessed 4 June 2016.

- BREEAM New Construction, Non-Domestic Buildings, Technical Manual SD5073-3.3:2011, BRE Global, 2012.

- Ventilative cooling of a seminar room using active PCM thermal storage – accessed 4 June 2016.

- CIBSE TM57, Integrated school design, CIBSE 2015.

- Baseline designs for schools: guidance – accessed 4 June 2016.