The school’s well-insulated and airtight façade features Innovare structural panels and high-performance glazing

For a long time now, the schools and colleges sector has been at the forefront of energy efficient design. The energy efficiency standards in the Department for Education’s (DfE’s) Output Specification have steadily increased over the past decade, and while, initially, this was more about reducing operational costs than emissions, it has meant the sector was the first to adopt a swathe of measures, such as predictive energy modelling, to try to make its building stock the most energy efficient in the UK.

Despite this industry-wide push, however – and engineering calculations that indicate usage will be lower – consultants and contractors are hesitant to trust the efficiency of all-electric systems. They are also inexperienced in determining accurately the peak electrical loadings for all-electric buildings.

They do not understand, or are not ready to believe in, the efficiency of these recent technologies. This is partly because they are not willing to trust the calculations made in the design stages and tend to overdesign margins. This is a significant barrier to widespread adoption of all-electric designs – not just in schools, but in all types of buildings.

As the first wave of all-electric schools start to reach completion, it is up to building services engineers to bridge the gap and help educate the industry, so we all have confidence in the calculations. We need to look at how these first all-electric schools perform in operation by regularly measuring and reporting the performance.

This is not something we have historically been good at as an industry, and it requires a step change to get everyone on the same page. Once you start looking at these schools, numbers are clear, and they go a long way to helping understand actual demands and usage. They can then be fed back into calculations in the design stages of future schemes.

Project team

Client: Department for Education

MEP & sustainability consultants: Cundall

MEP subcontractor: Derry Building Services

Main contractor: Bowmer + Kirkland

Architect: Stride Treglown

Recently, Cundall was part of the project team that completed West Coventry Academy, a 12,000m2 secondary school with a sports block and swimming pool. Part of the DfE’s School Rebuilding Programme and Net Zero Carbon in Operation Pathfinder scheme, it was handed over in September 2023, and is all-electric in operation except for a small gas boiler that serves the pool’s water-heating system. The school has air source heat pumps (ASHPs) for heating and kitchen hot water, and direct electric hot water for everything else. It also has LED lighting and controls, and a small photovoltaic (PV) array (100% PV array was not specified in the brief, but there is room to add this in the future).

The building has a well-insulated and airtight façade, featuring Innovare structural insulated panels and high-performance glazing. The design peak heating load is 280kW, just 23W/m2. Ventilation is hybrid, incorporating mechanical ventilation units with heat recovery for all occupied spaces for tempered fresh air in winter, and natural cross-ventilation via circulation atria roof turrets for summertime ventilation. The only cooling is to the server room, and some classrooms have exposed ceiling fans to aid thermal comfort.

The school had taken part in the DfE’s ‘pathfinder scheme’ and, in 2021, had employed the then new DfE Output Specifications and technical annexes that had not been put into practice on any scheme previously, and had continued as a test location for these new specifications. When we designed West Coventry Academy, we called on our experience with a previous Priority School Building Programme project, finished in 2018, that we knew had resulted in a maximum in-use electrical demand of just 276kVA (17.2W/m2).

Many did not believe we had achieved such low figures, but we had the electric bills and meter readings to validate this over several years. With this in mind, we designed West Coventry Academy to have a maximum in-use electrical demand of 550kVA (48.2W/m2), and we were confident our design would generate results similar to previously acheived. When the design and build subcontractor took over at RIBA Stage 4, however, they were not so confident in our calculations and an 800kVA supply was installed.

Six months on from West Coventry Academy being handed over, the school has experienced a winter that included a particularly icy -8°C cold snap, on 18 January 2024. The Cundall team visited the site a few weeks later to gather data and discovered that the maximum demand recorded was just 398kVA (33.7W/m2) – lower than even we had predicted for maximum energy demand, and far, far less than the 800kVA supply that had been installed.

Consultants and contractors are hesitant to trust the efficiency of all-electric systems and inexperienced in determining accurately the peak electrical loadings

This is a clear demonstration of the efficiency of all-electric designs, even in extreme conditions. It also highlights the potential cost implications of overdesigning maximum electrical demand and the associated infrastructure and low-voltage supplies.

It is a habit that we, as an industry, have acquired after years of designing low-efficiency, poorly insulated gas-fired schools. This overdesign not only adds cost, but also carbon – in construction and for the school itself, which, potentially, is left with a lifetime legacy of higher standing charges for a capacity it will not use.

On a lot of new or replacement schools, this can lead to expensive substation upgrades and high-voltage network reinforcement, which, again, may be unnecessary for the school in the long term.

Another reason the industry tends to overdesign schools is that the BSRIA BG9 2011 design guide suggested an electrical services load of 35W.m-2 for naturally ventilated schools (or 50W.m-2 for mechanically ventilated ones), and this assumes that heating and DHWS energy is fed by gas or other non-electric sources. The guidelines are based on 12-year-old data from gas-fired heating and hot water, and haven’t been updated to account for all-electric schools. (BG 9 has now been superseded by BG 84/2024 ‘Space and Weight Allowances’ ).

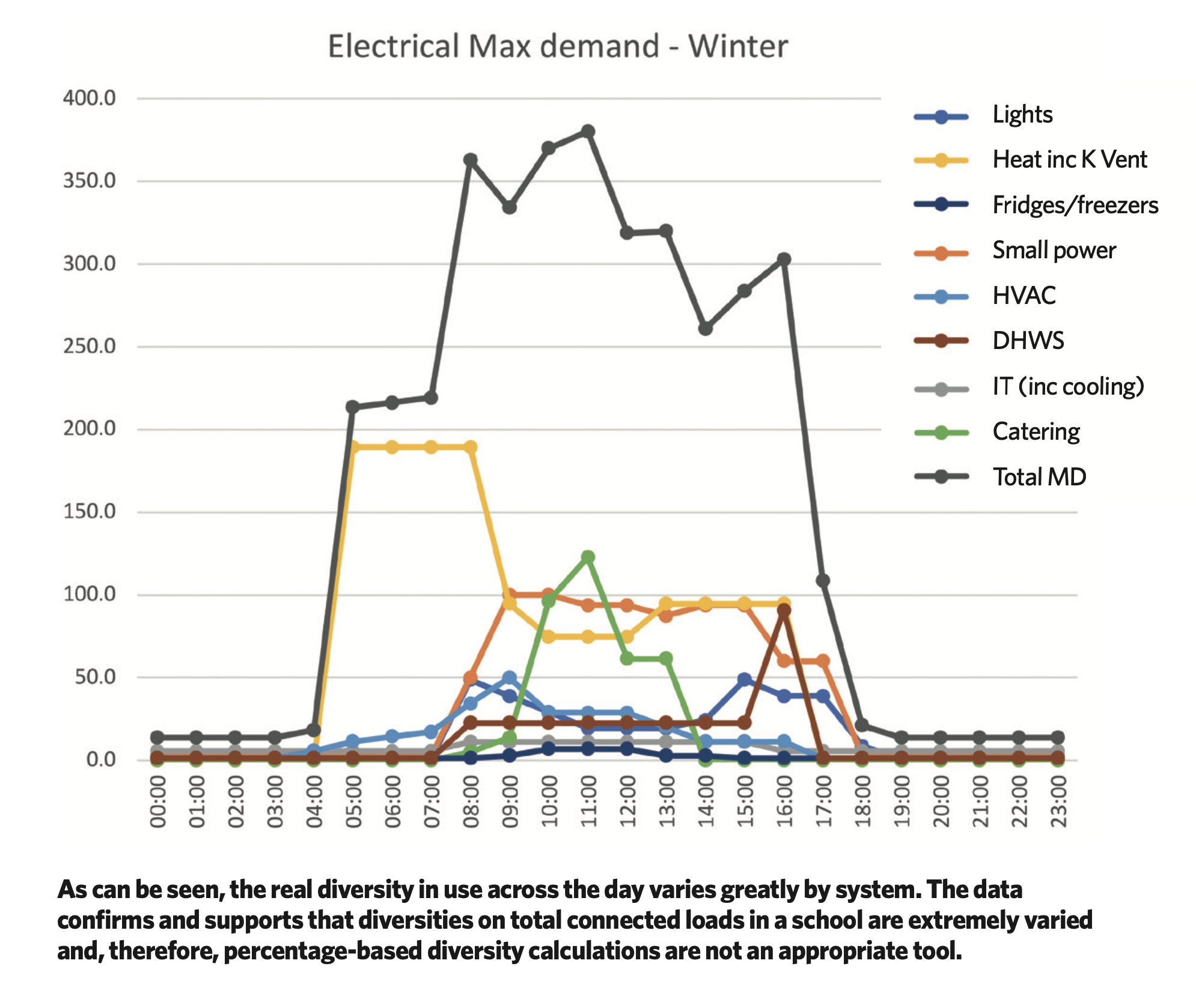

Typically, total connected loads are established based on good design data, and percentage-based diversity factors are then applied to equipment, ASHPs, domestic hot water systems, and other loads. These percentage based diversities are no longer appropriate.

In recent years, we have seen electrical infrastructure designs presented of typically 120W/m2 – nearly four times the maximum demand recorded at West Coventry Academy on the coldest day of the winter. Some designs are even higher, and this is clearly based on guesswork, not empirical data or good practice.

We cannot really blame designers for this; the guidelines have not kept up with the current rate of change when it comes to best practice on how we design our schools.

To counteract this problem, Cundall has established a school daily demand profile tool (see graph, above). The peak loads have been taken from actual meter readings of all-electric schools that we have designed. The daily data around these peaks is based on metered annual consumption data, with some adjustments applied depending on school specific facilities for design and technology or computing. BIN weather data is employed to simulate annual profiles based on the available data. When a full set of seasonal meter readings are available they will be used to improve the model.

West Coventry Academy has air source heat pumps for heating and kitchen hot water

The central premise is that the sum of all hourly and daily loads can be used as a check and equated back to an annual load. We must design schools to achieve specific DfE energy use intensity targets, expressed as kW/annum/m2, and, clearly, if these are exceeded in this check sum, you have overestimated a particular load.

This data can be extrapolated and used on any other school type to assist with future design estimates, and is a far more accurate way of calculating maximum in-use electrical demand until the guidelines catch up.

My hope is that we can speed up that process and replace the simplistic rules of thumb by feeding the irrefutable data we have collected already into upcoming design specifications.

In the meantime, the key for everyone in the industry, but especially building services engineers, is to keep measuring and reporting regularly on the in-use operational performance of the buildings we design.

- Peter Hazzard is a partner and schools sector lead at Cundall