The architecturally distinct Stephen Taylor Building (left) and Villa Building are set within a large garden in the West Cambridge Conservation Area

When it was completed in 2020, Cranmer Road was the first major Passivhaus development in Cambridge. The scheme for King’s College, in the West Cambridge Conservation Area, provides 59 new graduate rooms in two architecturally distinct buildings that respond to their urban contexts. The Villa Building and Stephen Taylor Building are, however, located within the same large garden, where three existing student villas are situated. The college decided to embrace Passivhaus construction after a costing exercise showed that the buildings’ low operational energy use would deliver a payback in the region of 25 years, when compared with schemes designed to current good practice and minimum compliance standards.

‘The payback, although not short, was enough to be well within the design life of the buildings,’ says Gwilym Still, director, Passivhaus leader and partner at Max Fordham, which was the project’s building services engineer, acoustic consultant and Passivhaus designer.

Project team

- Client: King’s College Cambridge

- Building services consultant: Max Fordham

- Architect: Allies and Morrison

- Main contractor: R G Carter

- M&E contractor: Munro

- Quantity surveyor: Faithful + Gould

Working with architect Allies and Morrison, Max Fordham set out to develop a scheme that would meet the stringent Passivhaus energy criteria, but that eschewed innovative construction methods and materials in favour of a more conventional palette. The design also accommodates the demands of graduate students, who were consulted throughout development of the brief. ‘We set out to build these buildings with standard components as far as possible, but applied in a different way to help with project delivery and demonstrate the scalability of Passivhaus,’ Still says.

The three-storey Villa Building occupies a gap between two Arts and Crafts-style villas on Cranmer Road. Its design is characterised by a brick façade topped by a tiled, pitched roof incorporating dormers and gables.

To provide lower-cost rentable accommodation, after consultation with the students, the Villa was conceived as a 19-bedroom house with shared bathrooms, kitchens, and a large kitchen-common room on the ground floor. The Stephen Taylor Building is located at the rear of the site.

Its modernist appearance is in response to this area’s more contemporary architecture. Behind its precast concrete and terracotta façade, bookended by grey brickwork stair enclosures, it incorporates 40 en suite study bedrooms spread over two storeys. The building also accommodates a large ground-floor common room that serves the entire campus. This building has been designed, structurally and from a building services perspective, to be able to accommodate an additional top floor at some point in the future.

Despite their different architectural treatments, both buildings are supported by a cross-laminated timber structure set on a concrete raft foundation, and both feature cavity wall construction using mineral wool as a partial fill.

Allies and Morrison says this construction method helped achieve a ‘remarkably good’ airtightness performance: the Villa Building achieved a permeability of 0.17m3/m 2 ·h (0.16 ACH), while the Stephen Taylor Building achieved 0.31m3/m 2 ·h (0.19 ACH), both at a pressure differential of 50 pascals.

The building services, too, are similar. Both buildings are all-electric, with space heating provided by direct electric panel heaters and domestic hot water supplied by point-of-use heaters, to minimise pipework heat losses, along with waste-water heat recovery.

‘We opted for an all-electric solution – even though, at the time, it was harder to achieve from a regulatory compliance point of view – because when you looked at the ongoing decarbonisation of the electricity Grid in the context of the design life of the building, the period when gas would be better than electric was vanishingly short,’ explains Still. Both buildings are orientated in the same direction, with their principal elevations facing north-south.

Max Fordham did some early-stage modelling of daylight levels and heat gains to establish parameters for the window sizes from which the architect could work. Still says Max Fordham revisited these assumptions as the design progressed to check that these parameters were still applicable. The scheme was designed before the publication of CIBSE TM59 Design methodology for the assessment of overheating risk in homes. Nevertheless, Max Fordham tested the scheme’s comfort performance against current and future weather files using IES dynamic thermal modelling. It also used the Passivhaus Planning Package (PHPP) to prove the scheme’s compliance with Passivhaus comfort criteria.

Both buildings feature continuous mechanical ventilation from packaged mechanical ventilation with heat recovery (MVHR) units incorporating summer bypass. The Villa Building uses a cascade system of air transfer, similar to that in a domestic house: two MVHR units on the top floor supply fresh air to the bedrooms; this spills into the corridors and, from there, to the kitchens, shower rooms and toilets, from where it is extracted. The Stephen Taylor Building is based on a series of single MVHR units serving clusters of four en suite bedrooms. In addition, two separate MVHR units serve the two pairs of kitchens.

The exposed cross-laminated timber design of a kitchen in the Stephen Taylor Building

‘The ethos behindthe scheme was to keep things as simple as possible from a ventilation point of view, so there is no interlock with the windows – if someone wants to open a window to increase ventilation, they can,’ Still explains. ‘On both buildings, extract is from the toilets, kitchen and bathrooms – so, if we turned off the vent when someone opened a window, the shower rooms would, for example, start to get humid.’

A single MVHR unit with summer bypass serves the campus common room in the Stephen Taylor Building. Still describes this room as ‘a special case’ because of its predicted intensive occupancy. Here, the MVHR unit incorporates a mini air source heat pump to automatically heat or cool the ventilation air. ‘While you could keep the common room comfortable for most conditions, there were enough hours where it was going to get uncomfortably warm that we put in active cooling,’ explains Still. Ventilation rates are increased further in summer, with windows opened by automatic actuators.

The common room also incorporates underfloor electric heating to keep walls clear of panel radiators. The building’s 100-year service life mean s items such as the MVHR units are designed to be accessible for service and to enable their replacement over the design life of the building. Still says the ductwork is less easy to replace, ‘but it is still possible’.

Monitoring performance

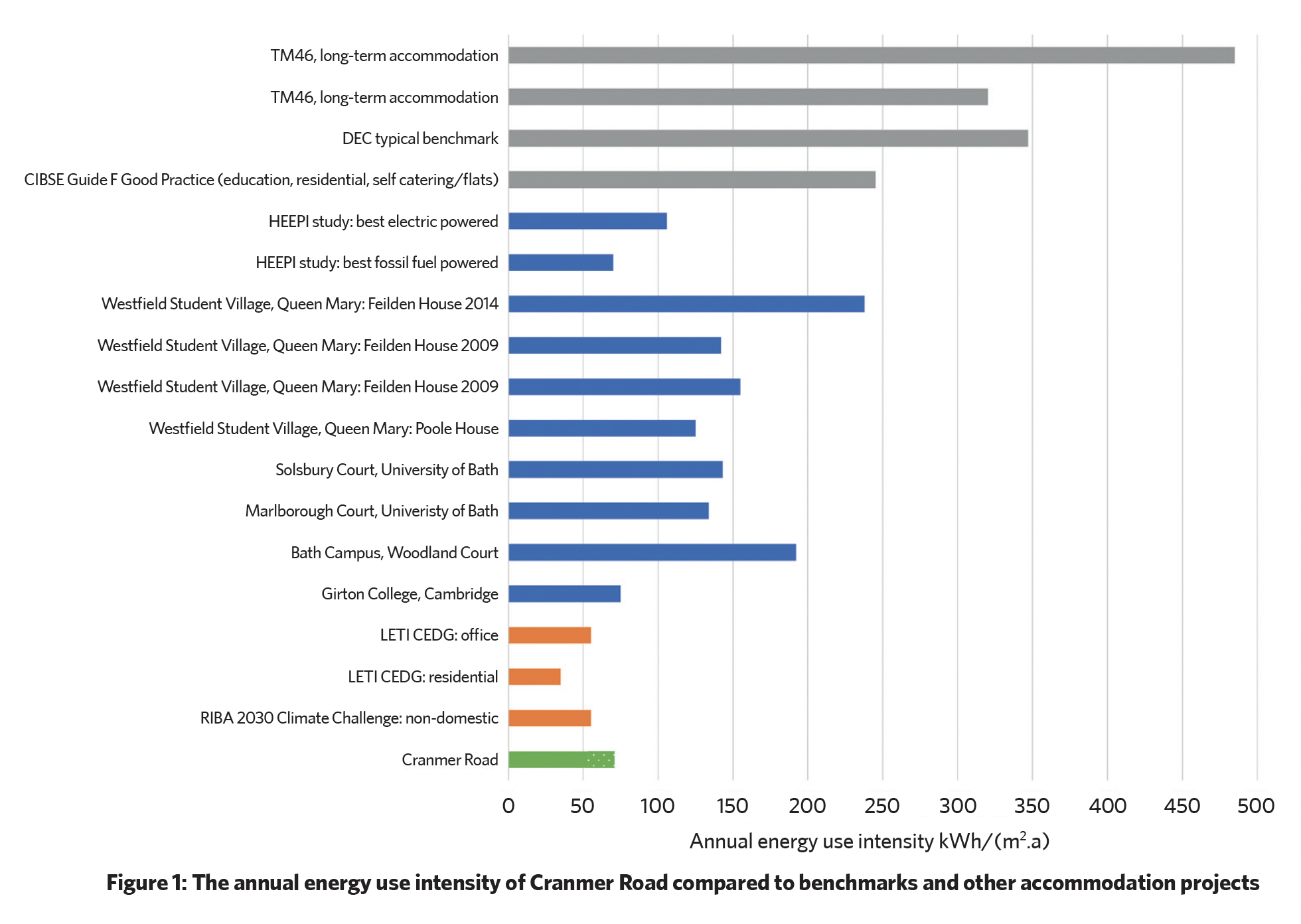

Energy use was reviewed later in the year and the total EUI had risen to 71 kWh·m-2 per year in response to some of the students overriding radiator controls. The radiators have built-in thermostats that were pre-set at 20°C. These are fi tted with a child-proof lock. As it turned out, these locks were not proof against determined undergraduates, who were reportedly turning the thermostats up to 26°C in some instances. As a consequence, annual energy figures are currently higher than those predicted by PHPP. ‘We provided the college with user guides to discourage students from tampering with the radiators,’ explains Still.

On subsequent projects, Max Fordham has refi ned this concept by providing local controls that limit temperature setpoint adjustment to a range of plus/minus 2°C. Monitoring also showed the students were using more domestic hot water (DHW) than the PHPP assumption, which was based on a five-minute shower duration. Clearly, King’s College students are cleaner than most and were taking seven- to eight-minute showers . ‘We learn ed that the PHPP assumptions for domestic hot water usage are lower than usage by the UK student population,’ laughs Still. ‘This has been fed back to the students, and into energy modelling on future projects, where it will influence system choice and energy usage predictions.’

The scheme was completed in December 2019. On handover, the facilities staff were trained in its operation. In addition, the design team and contractor remained engaged with the college post-occupancy, to answer queries and to help fine-tune systems. Post-occupancy monitoring of energy consumption took place and revealed student behaviour that differed from the design assumptions.

Post-occupancy monitoring of electricity consumption was undertaken from January to April 2020, before occupancy was interrupted by the Covid pandemic. The monitoring showed an expected building energy use intensity (EUI) of 53kWh·m-2 per year, with a peak hea ting load below 10W/m-2. Post-occupancy feedback was also gathered, informally and through a structured survey using BUS methodology, in April 2021.

Overall, the results were extremely positive, with the building scoring highly in areas such as comfort, lighting, noise, ventilation, effects on health, and appearance. However, the survey did pick up on the initial frustration of some students with the energy efficient lighting controls, which turned off lights earlier than desired in toilet and shower areas. This issue has since been rectified by simply extending the lighting control run-on period.

Max Fordham’s well-engineered approach and its response to student issues certainly made an impression on the judges at this year’s CIBSE Building Performance Awards, where the scheme won Project of the Year (Non-Domestic) . The judges were impressed by the consultant’s focus on optimising building energy performance, and they highlighted the use of feedback from the occupant surveys and the scheme’s comprehensive approach to commissioning. They also admired how detailed analysis of the impact of a range of future climate scenarios had influenced the design and construction of the two buildings.