Is this the UK’s greenest commercial building? The Enterprise Centre at the University of East Anglia (UEA) in Norwich is targeting BREEAM Outstanding and Passivhaus certification. Designed to last for 100 years, it has been built on a brownfield site using 70% bio-based materials, many of which have been sourced locally. And it exceeds local planning requirements for 10% of the building’s energy to be from renewables, with a 480m2 roof-mounted photovoltaic array, predicted to generate 44MWh a year.

Consequently, over its lifetime the building’s embodied carbon is predicted to be one quarter that of a conventionally constructed building.

This pioneering two-storey 3,400m2 building is the new home for the Adapt Low Carbon Group, which was created to commercialise graduate start-up firms that have grown out of UEA’s world-class environmental sciences.

Adapt wanted its new facilities to be an exemplar of sustainability. ‘There is no point in being a lead institution on climate change if we don’t act on our values and build a site that can help mitigate climate change and can cope with its impacts,’ says group CEO John French.

Project team

Client: University of East Anglia

Developer: Adapt Low Carbon Group

Contractor: Morgan Sindall

Architect: Architype

M&E: BDP

Lifecycle cost analysis:BSRIA

The biggest clue to the £11.6m building’s climate mitigation aspirations is its cladding – the building is wrapped in thatch. In a dramatic reinterpretation of the use of this traditional Norfolk roofing material, the thatch is formed of 250mm thick layers of straw set in prefabricated, vertically-hung timber cassettes – a world first according to Morgan Sindall’s senior site manager Ken Bassett.

The thatch holds the carbon absorbed by plants photosynthesising for 100 years or so. ‘We recognised thatch would be a good carbon negative local material,’ Bassett explains.

The unique cassette system was developed under a single point delivery contract by Morgan Sindall and project architect Architype. The cassettes were thatched horizontally by local thatchers, who were able to carry out the work safely in barns through the winter when traditionally there is very little work for them. ‘Once all the panels were in place, a thatcher came along and dressed the wall with a machine like a large hedge cutter to give the building a haircut,’ says Bassett.

The amount of carbon embodied in the building’s thatch cladding cassettes was calculated by Architype using its newly developed Rapiere software, using information taken from the project BIM model

The use of cassettes has enabled this traditional material to be installed in much the same way as conventional cladding panels. Significantly, the panels sit outside of the building’s airtightness and insulation line and are not part of the structure.

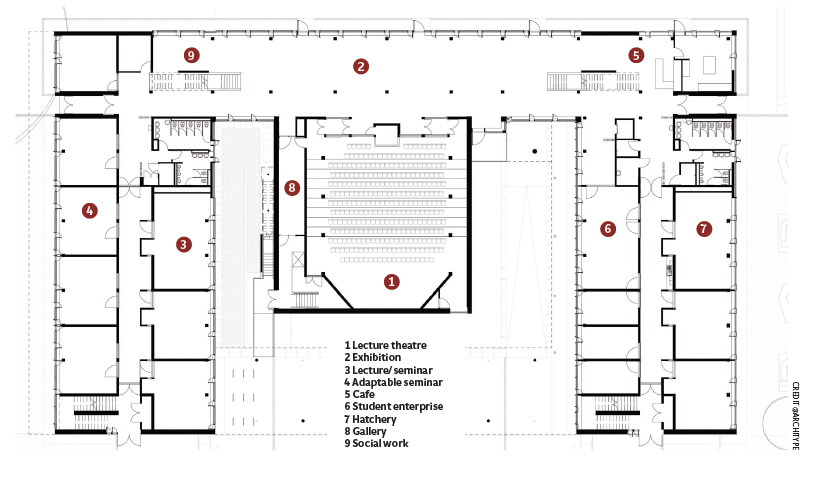

Thatch cladding features on every elevation of this E-shaped building. The building’s form was the result of the need to maximise the amount of daylight. The top and bottom elements of the E are formed by the two main wings, one of which is for teaching, and the other for start-ups. The building is orientated such that the wing façades face north and south. A predominantly transparent block links the wings, in its centre, and forming the middle of the E is a 300-seat auditorium.

Achieving CO2 targets

The amount of carbon embodied in the building’s thatch cladding cassettes was calculated by Architype using its newly developed Rapiere software, using information taken from the project BIM model.

The client set the design team a target of 500kg of emitted CO2 per square metre over the 100-year life of the building. This meant that every material was selected based on an assessment of embodied carbon and cost.

Straw was locally sourced in East Anglia

‘Normally I’d look at cost and programme when selecting materials but here it was a complex equation. We had to look holistically to ensure we reached the optimum balance between achieving BREEAM and Passivhaus targets, minimised embodied energy and lifecycle costs while ensuring we met the construction programme,’ explains Bassett.

The building’s foundations were one area where the team had to work extremely hard to find an appropriate solution. The building is supported on a glulam timber frame.

The amount of carbon embodied in the building’s thatch cladding cassettes was calculated by Architype using its newly developed Rapiere software, using information taken from the project BIM model

Originally it was proposed the frame would be supported on small concrete pad foundations and that the building would feature a timber ground floor supported from the glulam columns.

However, Morgan Sindall’s geotechnical investigation revealed a site dotted with sinkholes and the remnants of a glacial riverbed. This resulted in the pad proposal being abandoned, along with the timber ground floor, in favour of a 375mm thick concrete raft foundation incorporating three layers of 98% recycled steel reinforcement.

Not just a cement mix

Concrete has a high level of embodied carbon as a result of the use of cement produced by heating Portland stone to about 1,400°C. ‘Using 1,000m3 of ordinary concrete for the raft would have knocked the project way off its carbon target,’ Bassett explains. Morgan Sindall worked in partnership with its concrete supplier to produce a mix incorporating ground granulated blast furnace slag, which allowed 70% of the cement to be removed from the mix. In addition, recycled sand and responsibly sourced aggregate were also used. ‘This concrete had 38% embodied carbon when compared to ordinary concrete of a comparable mix,’ proclaims Bassett.

The building’s glulam structural frame was sourced from abroad because there are no commercial-scale glulam manufacturers in the UK

The raft was cast on a base of Isoquick polystyrene insulation, positioned on a sub-base formed from crushed, recycled basement salvaged from the demolition of a nearby hospital. For this project the manufacturer developed special polystyrene kerb units which not only removed the need for shuttering but, equally importantly, enabled the insulating envelope to continue from under the concrete raft to join up with the insulation in the wall minimising heat losses. ‘The solution worked brilliantly,’ says Bassett.

In keeping with the low-carbon philosophy, the raft’s top surface has been ground and polished to save on floor finishes. A carpet had been proposed as a covering for the ground floor; this would have been replaced under UEA’s maintenance strategy every seven years. ‘When we looked at the carbon embedded in using a carpet, it was actually more than was in the raft foundation, so we got rid of the carpet and went for a ground finish,’ says Gareth Selby, an associate at architect Architype.

The building’s glulam structural frame is supported by the raft. It was sourced from abroad because there are no commercial-scale glulam makers in the UK. The project does, however, make use of Corsican Pine – sourced from Thetford Forest some 30 miles away – in the construction of internal studwork walls.

Timber is also used for construction of the façade brise soleil. Future climate data was generated for this project by EA’s Climate Team for an 87-year period. Using this information, Architype simulated a range of design scenarios in Passivhaus Planning Package (PHPP) to optimise the façade design.

The analysis highlighted the need to rethink slightly the allocation of south-facing windows deemed essential by Passivhaus as a source of passive heating, to help limit internal gains.

CIBSE guidance on resource efficiency

The embodied energy strategy was highlighted as a case study in CIBSE TM56 Resource Efficiency of Building Services: 2014. Members can download this for free at www.cibse.org.uk/knowledgeportal

Cost for non-members is £50.50.

‘From the analysis we boosted shading slightly by setting the windows further back into the reveals,’ explains Selby. ‘From a future perspective we developed a timber brise soleil, which can be adapted to allow more louvres to be added in the future.’

Keeping cool

While the building’s lightweight construction has helped save on embodied carbon, there were some concerns that its lack of thermal mass could result in the building overheating, even in the current climate.

These concerns were mitigated, in part, by floor-to-ceiling heights in excess of 3.3m on both floors which helped create sufficient volume to cope with temperature rises and ensure good daylight levels on the floorplates. Aided by LED lighting and an intelligent control system this helped keep lighting loads to a minimum and kept the primary energy demand below 120kWh/m2/y.

The building is exceptionally airtight, even by Passivhaus standards. ‘We achieved an airtightness of 0.21m3/m2 at 50Pa, which is three times better than needed for Passivhaus compliance, and about 100 times better than is required under Part L,’ laughs Bassett.

A demand-led ventilation system controlled by occupancy and CO2 sensors delivers fresh air to keep occupants comfortable. The building has three ventilation plantrooms: one in each wing and one in the central auditorium. Each plantoom houses a Swegon Gold, Passivhaus certified, air handling unit (AHU) incorporating a thermal wheel.

Air from AHUs is ducted to the floors and distributed via Trox VAV units mounted in a services distribution bulkhead that doubles as an attenuated return air plenum. Air is extracted from the wings via the toilet blocks (there are no toilet extract fans); extracted air is then passed through the thermal wheel before being discharged to outside.

Unusually for a Passivhaus project, the Enterprise Centre does include a small amount of cooling in the 300-seat auditorium to ensure it remains comfortable in summer. This is provided by a small direct expansion system with a cooling coil positioned in the supply air stream and a heat rejection unit situated in the exhaust air steam. ‘We’re using cooling just to peak-lop the fresh air supply temperature in summer because the students will be dressed appropriately for the conditions,’ explains James Hepburn, engineer director at BDP, the project’s services engineer.

In the main floor areas there is no cooling. Instead occupants can open the building’s windows to provide ventilation [See panel ‘Window of opportunity].

The ventilation strategy, and other aspects of the scheme, were agreed with the UEA’s estates team, who were involved with the project under its Soft Landings initiative and led by Stuart Thompson, senior design manager at Morgan Sindall. This is a good thing because estates will probably need to be proactive in managing the operation of this highly value-engineered ventilation solution and innovative building.

Window of opportunity

There is no cooling to the main floor areas. However, when conditions allow, the occupants can open the building’s triple-glazed windows to provide ventilation. A display panel in each room contains two LED lamps, which are illuminated when outside air temperatures are suitable to allow windows to be opened. The CO2 sensors in the room will then detect improved air quality and back off the VAV damper serving that room. If temperatures are very hot, occupants are encouraged to leave the windows open overnight to allow night ventilation.

In winter heating availability is limited and controlled by the BMS. Heat in occupied rooms is provided by ‘tiny’ radiators, each fitted with a TRV. ‘We didn’t want to run the risk of not having heating in these rooms, because the building does not have automatic windows so there is a chance a window could be left open overnight,’ explains Hepburn.

Heat for the building comes from the UEA’s district heating system. The heating mains ran close to the building, which was fortunate because heat loss from the spur to the building had to be included in the Passivhaus compliance criteria. A heat interface unit incorporating two heat exchangers, one for the heating and one for the hot water – separates the building from the mains.

One of the biggest challenges in achieving Passivhaus compliance was the provision of hot water to toilet blocks. This is because standing heat losses from hot water pipes are factored into the PHPP spreadsheet.

The form of the building with its two wings meant the losses were so high that hot water in the southern wing, the one furthest from the heat interface unit, had to be provided by point-of-use local electric water heaters. Micro-bore pipework, which has lower standing heat losses, feeds the remaining hot water outlets.

As far as minimising embodied carbon goes, Hepburn says: ‘We did a fair amount of research looking at different materials but we were not satisfied with the robustness of alternatives in meeting the building’s 100 year life. The best you can do is install less M&E.’

One of the constraints of Passivhaus is becoming apparent now the building is in use. One challenge of gaining certification is that small power loads are included in the Primary Energy Demand maximum. As a result, the design team spent a lot of time selecting the building’s AV systems and, to keep small power loads to a minimum, the client was keen not to flood the building with electrical sockets. ‘Passivhaus is very challenging because it limits what you can do in terms of computers and catering, which we’re finding a little bit constraining,’ remarks French.

Bassett, meanwhile, has submitted his last spreadsheets for carbon emissions from deliveries and from the workforce. The sheets include all deliveries to site, including such details as where the vehicle was from, miles driven, type of vehicle, and fuel. ‘The threshold was less than 500kg/m2 emitted CO2 over the 100-year life including construction carbon – we think we’ll be 10% below that figure,’ says Adapt’s John French. ‘From my perspective we’ve set a new standard in sustainable architecture and it has not cost the earth’.