There is growing pressure on the building services industry from architect, building services engineer, contractor, equipment supplier and end-user to deliver heating and hot water solutions with ever-increasing system efficiencies. There is a move away from focusing on appliance efficiency to overall system efficiency, and to lifecycle environmental impact of products and solutions. This is also being driven by the Eco-Design of Energy Using Products (EuP) Directive – likely to be implemented across the whole of Europe within the next three years – which demands exceptionally high minimum system efficiencies within two years of its introduction.

The directive estimates that more than 80% of product-related environmental impacts are determined during the design phase of a product. Eco-design aims to improve the environmental performance of products throughout the lifecycle by ensuring that there is a systematic integration of environmental aspects during product design.

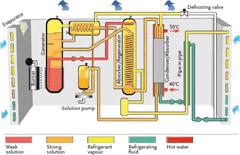

Fig. 1 : Internal thermodynamic cycle of a gas-absorption heat pump

In the UK there is also a need to work towards zero carbon homes in 2016 and zero carbon non-domestic buildings in 2019, which, enforced through local buildings codes and regulations, will also drive the new applications of heating technology.

Principle of operation

With traditional air-to-water heat pumps, electricity is used to power an induction motor that drives the refrigeration compressor. Air-sourced gas-absorption heat pumps use a gas burner to drive the refrigeration cycle, which draws on the available energy from the surrounding ambient air to increase the thermal output significantly above that provided by the gas input. The output from the heat pump can be used to supply low-temperature hot water for space heating and/or for the production of domestic hot water via an indirect cylinder, similar to a traditional boiler. Ground-sourced gas-absorption heat pumps are based on the same principle of operation, except that the energy collected from a ground loop (trenches or bore holes) is used to augment the heat generated by the combusting gas to produce highly effective fuel efficiencies (in just the same way as with electrically powered ground source heat pumps).

The gas-absorption heat pump comprises a sealed thermodynamic circuit, normally containing an ammonia water solution that acts as the working fluid, with ammonia being the refrigerant and water the absorbent. Traditional air-to-water electric heat pumps typically use modern fluorinated refrigerants (such as the HFCs R407C and R410A) that, although less damaging than the previously used CFCs, still have a signicant global warming potential (GWP).

Ammonia, a naturally forming chemical, offers no harmful effects to the ozone layer. The ammonia water working fluid has zero ozone depletion potential (ODP) and zero GWP. Apart from the intrinsic environmental benefits, a low GWP also provides a credit when assessing BREEAM (Building Research Establishment Environmental Assessment Methodology) ratings for the building; and similarly the lack of CFC will ensure that the Energy and Atmosphere prerequisite for the LEED (Leadership in Energy & Environmental Design) rating system’s Fundamental Refrigerant Management will be satisfied, [1].

Ammonia refrigerant is toxic and flammable. However, the commercially available units are designed for outdoor installation. The heat pumps contain a fully sealed ammonia circuit, with no need for any contact with the fluid during operation or servicing. The risk of hazardous ammonia escape is therefore significantly reduced.

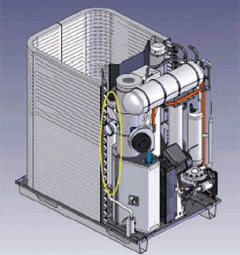

Fig. 2 : Internal view of a gas-absorption heat pump

Considering the circuit shown in Figure 1 with reference to the bottom right of the diagram, the condensed refrigerant is expanded and enters the evaporator at a relatively low temperature and pressure. Heat is thus drawn into the system from the surrounding air by the ‘evaporator’ as the ammonia evaporates (the evaporator is shown diagrammatically wrapping around the other components – this can be seen more clearly in the sectional diagram of a production unit in Figure 2).

Heat is also added into the system by the gas burner as it heats the refrigerant and absorbent solution in the ‘generator’ – this should ideally be configured to allow condensing of the combustion gases to maximise performance. This heat is being used to ‘boil out’ the ammonia from solution, so that the now higher temperature and higher pressure ammonia vapour can pass into the top of the ‘condenser’ (that is shown combined with the systems ‘absorber’) and exchange heat to the return water from the heating system (shown in this example at 40C) so that the ammonia condenses and returns via the expansion device back to the low pressure evaporator (to receive more heat from the surrounding air).

At the same time, the absorbent (water) from the generator, after the refrigerant is boiled out, continues to another heat exchanger called the ‘absorber’, which is at low pressure. It is here that the ammonia vapour and water join up again generating further heat as they combine. The heat is extracted in the condenser/absorber section to improve system efficiency. The now cool low-pressure mixture is pumped back to the generator, using the solution pump to complete the process.

The water (from the building heating circuit or coil of an indirect cylinder) is raised in temperature, which in this case is by 10K. The water used as an absorbent is quite separate from that circulating in the heating system. (For a more complete description of the absorption refrigeration system, see the CIBSE Journal CPD article from November 2009 – available online at www.cibsejournal.com).

Applications

Gas-absorption heat pumps can be utilised in schemes that would traditionally use boilers for space heating applications. As the heat pump is typically designed for outdoor installations, the plant room size could be reduced, thereby offering space efficiency as well as fuel efficiency. An example of a 41kW heat pump is shown in Figure 3.

Fig. 3 : A commercial gas-absorption heat pump

As with most types of heat pumps, the optimum performance available from gasabsorption heat pumps is achieved when supplying low temperature loads such as underfloor heating. Here water outlet temperatures at, for example, 35C to 45C are more appropriate for heat pumps compared with traditional radiator circuits requiring temperatures around 80C.

Gas-absorption heat pumps are also capable of producing domestic hot water with temperatures in excess of 65C via an indirect cylinder, in a similar manner to conventional commercial boilers. However, the efficiency would be significantly reduced to reach required storage temperatures for the potable (or domestic) hot water to prevent risks from legionella bacteria. (See section 5 of CIBSE TM13 [2] and HSE ACoP L8 [3] for guidance on averting the risk of Legionnaire’s disease).

For larger load applications it is possible to connect multiple gas-absorption heat pumps to ‘cascade’ through the use of a digital controller. In the case of some products this can allow the linking of many units to provide total installed capacity of several megawatts.

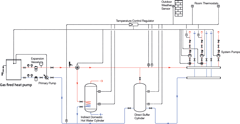

Using appropriate controls, it is possible to design and install a system where a combination of gas absorption heat pumps and commercial boilers are used i.e. bivalent systems. Here the gas absorption heat pump capacity may be selected to match the base thermal load of the building, as a technology to contribute to achieving a low carbon footprint. The commercial boilers would operate in the event that the thermal load exceeds the heat pump output. Alternatively the heat pumps could be sized for the lower grade heat loads (underfloor heating and hot water pre-heat) with the commercial boilers serving the higher temperature radiator circuits or main hot water calorifier. An example application of a gas absorption heat pump supplying heating and domestic hot water is shown in Figure 4.

Fig. 4 : Schematic of example system

Gas-absorption heat pump performance

Gas-absorption heat pumps deliver a high level of fuel efficiency during operation, compared to traditional heating boiler plant, if used with lower load temperatures of around 35C. Higher efficiencies can still be achieved at load temperatures of up to 50C. During operation, the refrigerant cycle uses natural gas (or LPG or, potentially, biogas) assisted by the energy in the air, rather than electricity to provide heat. As the carbon emission factor for gas is lower than gridsupplied electricity,(grid supplied electricity = 0.544 kgCO2/kWh and natural gas = 0.184 kgCO2/kWh [4],) improved emission reduction benefits are offered, compared with traditional electric heat pumps. Ongoing heatpump operating costs are also lower.

The starting current of a gas absorption heat pump is considerably lower compared with more conventional ground and airsource heat pumps, reducing the reliance on local electricity supply infrastructure. There is no compressor used within the refrigeration cycle – the solution pump (see Figure 1) used within the system to raise the solution pressure only consumes a small quantity of electricity; for example, for a 41kW gas-absorption heat pump, the electricity requirements for the solution pump is only around 1.1kW.

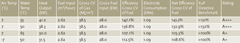

Overall gas-absorption heat pump performance is measured in efficiency terms, and not simply the traditional coefficient of performance (COP). Table 1 outlines the performance of an example unit when used with different ambient air temperatures and water flow temperatures.

Table 1 : Schematic of example system

By combining the energy available from natural gas with that extracted from the surrounding ambient air, gas-absorption heat pumps offer extremely high fuel efficiencies. For example, with an ambient air temperature of 7C and a water load temperature of 35C, a heat pump efficiency of around 143% can be achieved. This is the efficiency using the gross calorific value of natural gas and after deduction of the parasitic loss (ie the solution pump, fans and controls energy use). If applied in the appropriate manner, they have the ability to deliver fuel efficiencies that attain the A+++ level, which is likely to be defined under the EuP Directive.

Conclusion

Gas-absorption heat pumps offer an innovative, high-efficiency solution for lowgrade heating and hot water generation solutions, whether used on their own or in conjunction with commercial boilers; and their use can contribute to reduced carbon emissions and improved building environmental ratings. With the increasing pressure being applied to the UK heating and ventilating sector to deliver solutions with higher efficiencies and a lower carbon footprint, gas-absorption heat pumps have the potential to provide part of the solution.

© Tim Dwyer and Yan Evans

- The Leadership in Energy and Environmental Design (LEED) 2009 for New Construction and Major Renovations Rating System. www.usgbc.org/ShowFile.aspx?

DocumentID=7244 Accessed 24/8/2010 - TM13 2002: Minimising the Risk of Legionnaire’s Disease. CIBSE, 2002

- ACoP L8 – Legionnaire’s disease: the control of legionella bacteria in water systems. HSE, 2000

- Conversion factors – Energy and carbon conversions – 2009 update. Carbon Trust, 2010