In a recent UK government research briefing,1 heat pumps were reconfirmed as a key technology for achieving net zero emissions from domestic heating. However, the UK government target of 600,000 installations per year by 2028 still appears somewhat ambitious, being that just 72,000 were installed in 2022.

The research briefing asserts that heat pumps are technically suitable for most UK homes if installed appropriately. However, although the supply chain has significant growth potential, stakeholders indicate it is currently constrained by a lack of consumer demand and government policy uncertainty. Some of this uncertainty and lack of demand is doubtless the result of heat pump trials undertaken earlier this century that, in many cases, suffered from poorly or inappropriately applied installations and lack of understanding, variously by designer, installer and operator.

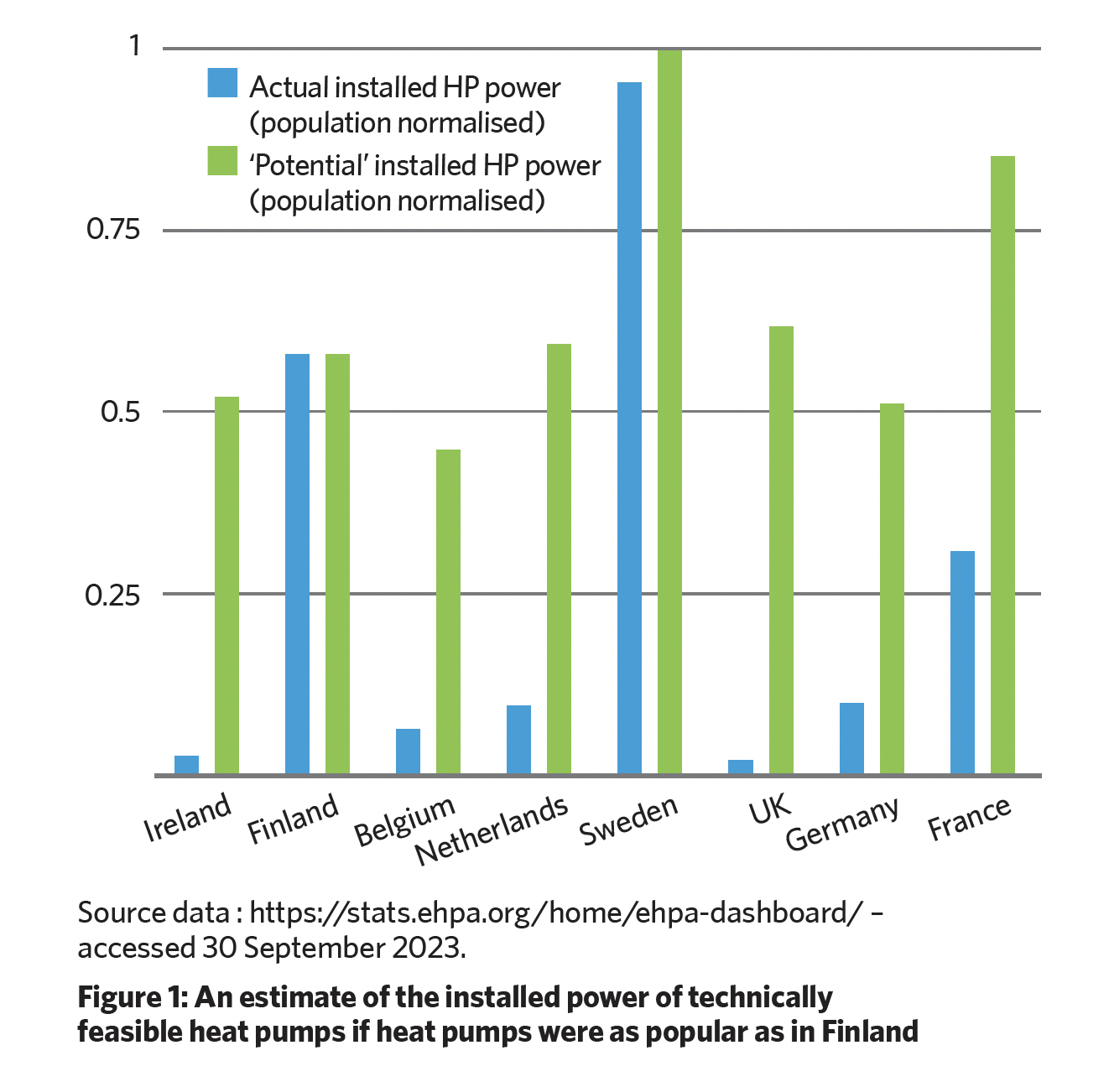

This reluctance to apply heat pumps is not apparent in many European states – many of which have climates that are similar, or more extreme, than those of the UK. An interesting set of data was produced by the European Heat Pump Association (EHPA),2 based on sales intelligence and methodology from EU Decision 2013/114/EU.3 This explored how many heat pumps were technically feasible across other European countries if heat pumps were as popular as they are in Finland.

These are reflected in the chart in Figure 1 – the green columns indicate the potential and the blue columns indicate the actual amount of renewable energy produced by the current stock of heat pumps. This data reflects all heat pump sales, and although the comparisons may not be absolute in their methodology, the strong indication is that there is much untapped potential still to be exploited in many countries.

The UK has4 around 412 heat pumps per 100,000 people, compared with a European average of 3,068 heat pumps per 100,000 people. The Climate Change Committee projects5 that to reach net zero, domestic heat pumps will be needed in at least half – but likely closer to 80% – of UK homes by 2050. There are approximately6 27 million homes in the UK and 68 million people.7

Air source heat pumps (ASHPs) employ an air-to-refrigerant evaporator coil to directly extract heat from a fan-assisted airflow. This coil features fins on the airside and is typically situated outdoors, utilising the surrounding ambient air as a heat source, or potentially in an air stream that is warmer than outdoor, ambient temperature, such as an exhaust air duct.

The condenser is often a compact plate heat exchanger that draws heat from the condensing refrigerant to increase the temperature of water that is being employed to supply the heating load. (Such an ASHP would be known as an air-to-water or air-to-brine heat pump.) The coefficient of performance (COP) provides an instantaneous measure of refrigeration cycle performance.

To achieve the best COP, the source (air passing over evaporator) should have as high a temperature as possible and the condenser temperature – governed by the temperature of water returning from the heating load – as low as practicably useful. To allow comparisons between systems and regulatory limits, the conditions for the measurement of the COP are typically standardised – for example, Approved Document Part L of the England Building Regulations (AD L England) refers to the methods of BS EN 14511-2.8

The seasonal COP (SCOP) is an aggregated COP over a year and, again, the calculation employs prescribed sets of external climate (temperature) bins and operating hours – these are defined in BS EN 14825:2018.9 SCOP values typically range from 3.0 to 5.0 for modern ASHPs.

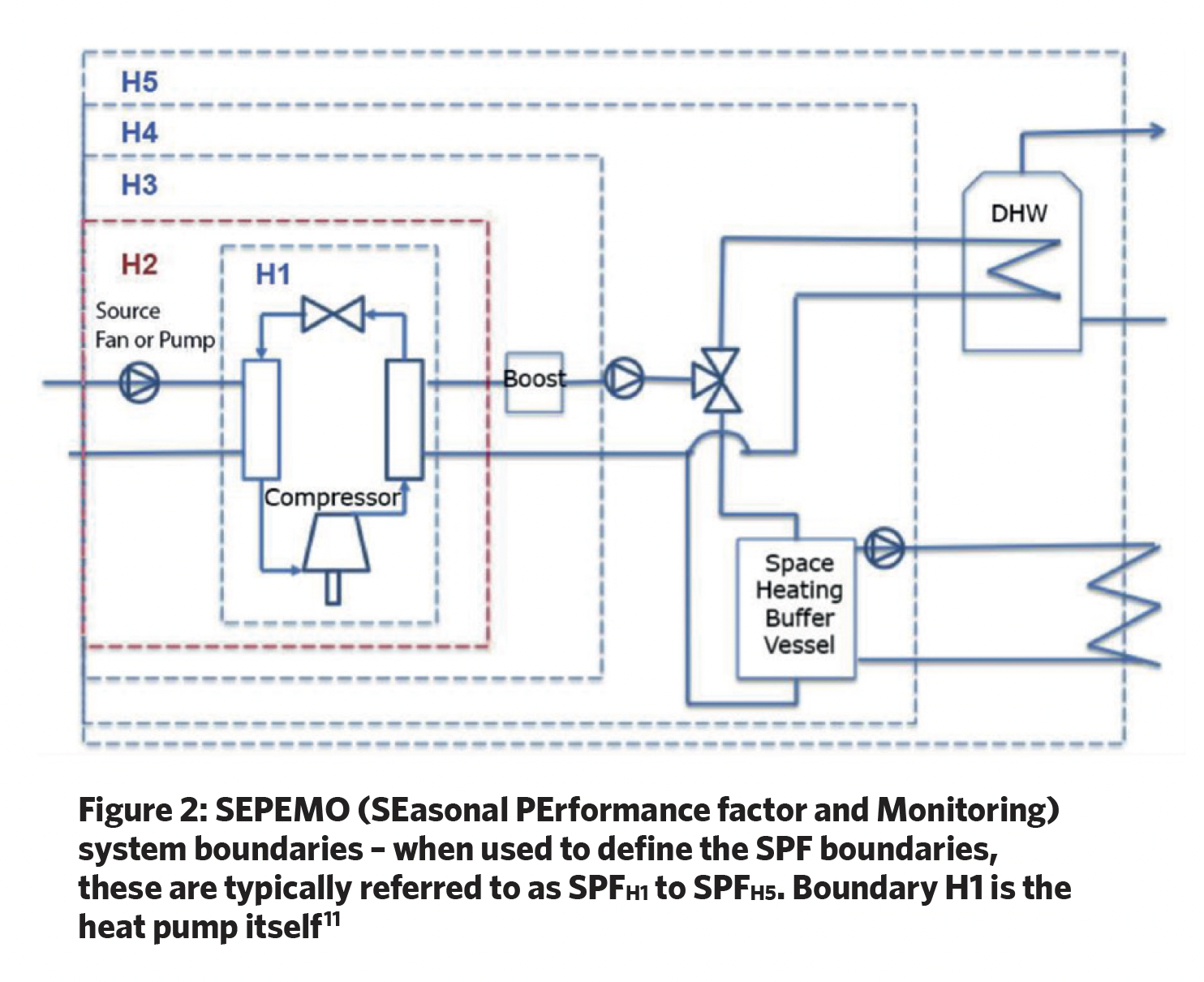

The seasonal performance factor (SPF) is often employed to assess the performance of the whole defined heat pump system aggregated and averaged across yearly operation. This accounts not only for the changes in COP as the evaporator and condenser temperatures vary, but also other de-rating factors – such as the de-icing cycles required to keep the evaporator clear of ice at low outdoor temperatures, and parasitic power used in fans and control systems.

Therefore, the SPF value includes all the relevant ancillaries associated with the particular building, whereas COP is associated with the heat pump unit itself. There are various defined sets of assumptions for ‘boundaries’ (of the equipment/environments to be included) in SPF assessments that will impact the calculated value. These are illustrated in Figure 2.

For air-to-water heat pumps, ADL England requires a COP of at least 3.0 for space heating, and 2.0 for domestic hot water (with prescribed sets of standard inlet and outlet conditions both for internally and externally located heat pumps). Heat pumps designated as low-temperature would not typically deliver heating water higher than 52°C, and medium- and high-temperature heat pumps are characteristically capable of typically delivering water at higher temperatures.

Where a heat pump is providing useful cooling as well as delivering heating, the overall performance will be significantly higher.

The UK government-funded ‘Energy Systems Catapult’ electrification of heat demonstration project10 installed 742 heat pumps in existing homes across Great Britain in 2020/21. The recently published interim findings found that ASHP SPFs have significantly improved, by ~0.3 to 0.4 compared with earlier trial installations reported11 in 2017, with the median SPFH4 for ASHPs being 2.80 (median SPFH2 = 2.94).

It is noted that heat pumps using the ‘low-GWP’ refrigerants R290 (propane) and R32 generally performed better than those using the older R410a refrigerant (which is currently being phased out in the UK). This result may also suggest that the design (and installation) of heat pump systems has also improved. However, it also found a need to improve the quality and consistency of heat pump designs and installations to support a large-scale rollout of heat pumps in existing homes, and deliver positive energy, carbon and consumer outcomes.

Median ASHP efficiency fell to 2.44 on the coldest day (-0.4°C), which quantifies the expected degradation in performance resulting from low temperature, and could be used to inform modelling of peak winter demand. Notably, the best-performing installations had the largest proportion of the annual load met solely by heat pumps (with lower use of supplementary systems).

Exhaust air heat pumps (EAHPs) are a specific application of ASHPs, combining an ASHP with a mechanical ventilation system. As noted in BSRIA BG 7/2009,12 exhaust air is an alternative heat source to outdoor air for buildings designed with mechanical ventilation.

The exhaust air is always at the indoor air condition, and so the source-to-load temperature difference is relatively small. The evaporator also gains from the latent heat in the exhaust air. The exhaust air may be drawn through the dwelling via transfer grilles or ducted from different areas including wet areas (but not from cooker hoods).

EAHPs are a form of mechanical heat recovery, but are many times more effective than simple air-to-air heat exchangers or runaround coils. EAHPs may be employed to provide heating, domestic hot water (DHW) and mechanical ventilation in domestic and small commercial applications, via a single integrated unit that requires no external plant or equipment. They are best suited to buildings with high thermal performance and low leakage envelopes. If required, complementary heating can be provided from either a supplementary heating system or through resistive-electric heating.

The associated mechanical ventilation system will likely be one of two types – centralised mechanical extract ventilation or balanced supply and extract ventilation. For centralised mechanical extract ventilation-based systems, background ventilation is required through purpose-designed background ventilation devices that are intended to perform with EAHPs.

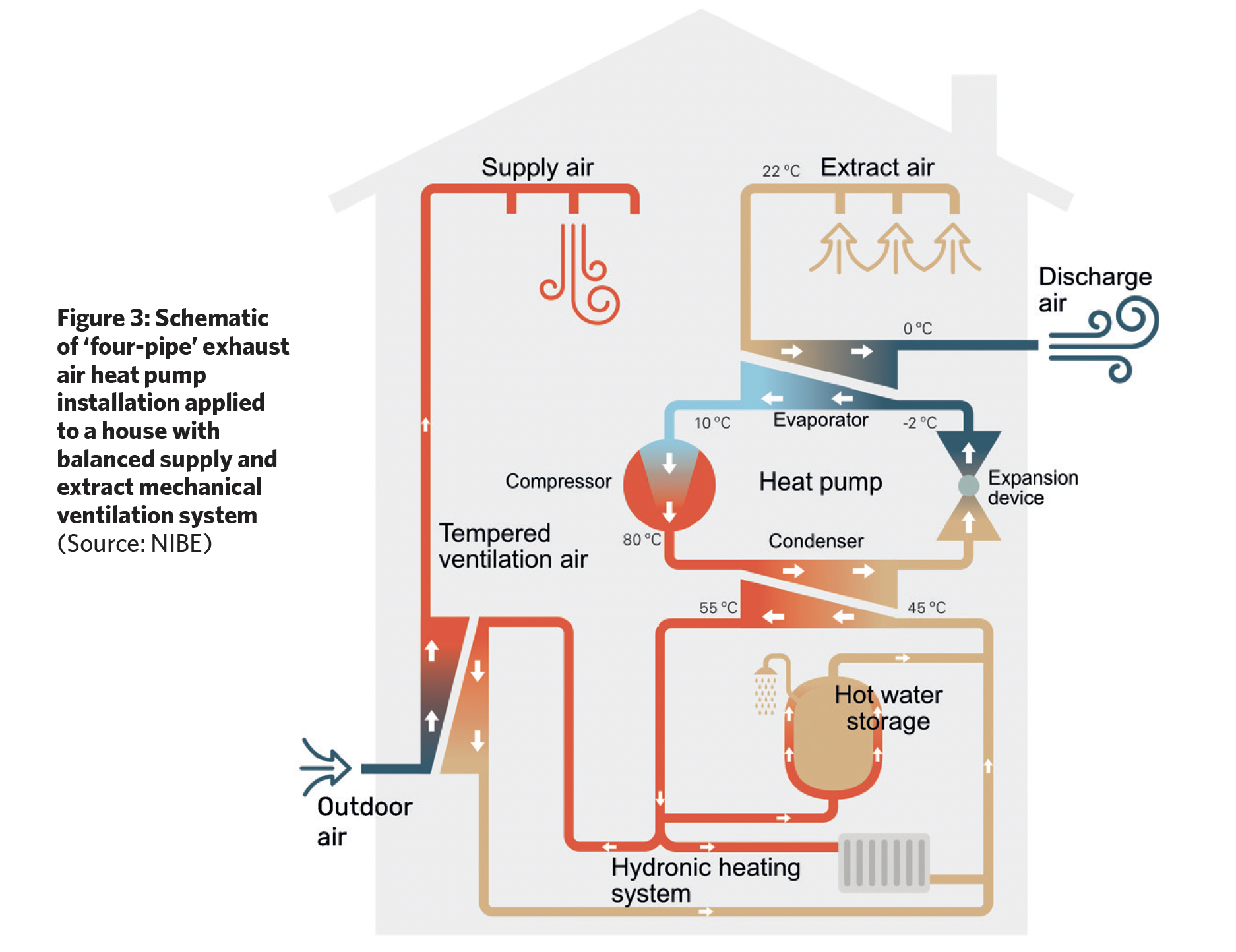

There is a common misconception that EAHPs – when operating as ‘four-pipe’ balanced ventilation devices, as illustrated in Figure 3 – follow the same principles as mechanical ventilation with heat recovery (MVHR) systems. However, unlike MVHR, where heat recovery and energy transfer is achieved by employing an air-to-air heat exchanger, the most common EAHP systems use an air-to-water heat exchanger to deliver heat from the heat pump condenser.

In a ‘four-pipe’ balanced ventilation system, the incoming outdoor air is tempered using another water-to-air heat exchanger that is fed from the heating system. The efficiency afforded by the heat recovery is therefore incorporated into the overall SCOP for the heat pump, and not as a thermal efficiency rating that is commonly assessed for an MVHR system.

The amount of available heat will be proportional to the extract airflow rate. To avoid over-ventilating the property – and, in turn, increasing air changes leading to higher heating loads – the ventilation system should be designed to meet the ventilation rates required to meet compliance with the local regulations (for example, in England, Approved Document Part F1, 2021).

To achieve higher EAHP heating outputs, it is possible to incorporate an additional, dampered, outdoor air duct that can be used to selectively draw outdoor air across the heat pump evaporator. Such hybrid source systems are recognised by the UK standard assessment procedure (SAP) PCDB (product characteristics database) as ‘mixed exhaust air and outside air heat pumps’.

Including hybrid source EAHP in SAP

Within SAP modelling, an EAHP can be entered under multiple categories in order for the model to recognise all the different aspects of the system. This includes a listing as a ventilation device, and also a listing as a heat pump for main heating and hot water production. EAHPs are a recognised technology under the UK’s Microgeneration Certification Scheme13 (MCS).

EAHPs require a hydronic heating emitter system, and most commonly incorporate an indirect unvented hot water cylinder. They work most efficiently at lower heating flow temperatures – as with other heat pump technologies – with distribution systems designed for delivering the required heating load at a maximum supply temperature of 55°C; this coincides with the most recent requirements in ADL England.

Most EAHP systems incorporate weather compensation control for the heating system and, potentially, inverter-driven compressors to modulate outputs. By employing refrigerants such as R290, EAHPs (such as in Figure 4) can deliver temperatures up to 70°C for the provision of hot water, allowing for legionella cycles to be carried out without relying on top-up electric heaters.

The heating delivered through either a hydronic heating system – such as underfloor heating or radiators – or, where balanced supply and extract mechanical ventilation is employed, potentially through both tempering the incoming air and supplying a hydronic heating system (as shown in Figure 3).

The specification and design of an EAHP system is critical to ensure that it operates efficiently and can provide 100% of the required heating and hot water demand. There have been several historic examples of trialled systems that were inappropriately matched to homes, which resulted in installations that were incapable of meeting loads without undue use of ‘backup’ direct electric heating.

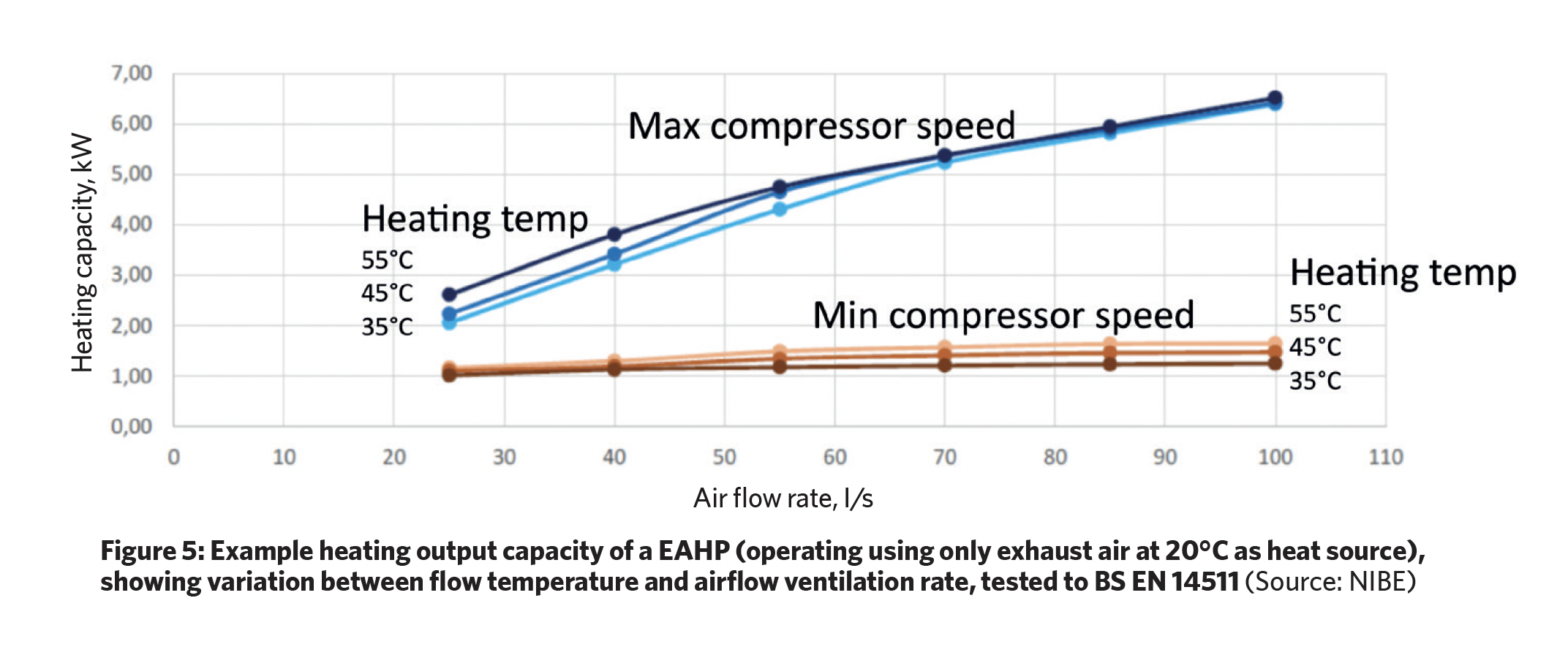

A full heat-loss assessment should be undertaken and the DHW demand should be carefully assessed prior to considering any heat pump application. Based on current Building Regulations fabric standards, and depending on appropriate configuration, commercially-available packaged hybrid source EAHPs – with outputs such as those illustrated in Figure 5 – may be applied to meet the heating demands for new dwellings up to approximately 150m2; in the UK this is a typical three (or more)-bedroom house.

As noted in in the UK parliament guidance,1 heat pump installation costs are higher than gas boilers, and large cost reductions are unlikely; however, heat pumps currently have similar running costs to gas boilers. With more creative tariffing, additional government initiatives, or greater energy security the relative gas and electricity cost differential may eventually erode – but, regardless, there is a prerogative to install heat pumps. For domestic and small commercial applications, properly integrated packaged EAHPs can provide one of the options to meet the ambitious target of 600,000 installations per year by 2028.

References:

- bit.ly/CJNov23CPD1 – accessed 4 October 2023.

- bit.ly/CJNov23CPD2 – accessed 4 October 2023.

- EU decision on guidelines on calculating renewable energy from heat pumps from different heat pump technologies (2013/114/EU).

- bit.ly/CJNov23CPD3 – accessed 4 October 2023.

- The Sixth Carbon Budget The UK’s path to Net Zero, UK Committee on Climate Change December 2020.

- bit.ly/CJNov23CPD4 – accessed 4 October 2023.

- bit.ly/CJNov23CPD5 – accessed 4 October 2023.

- BS EN 14511-2.

- ABS EN 14825:2018.

- Electrification of Heat Demonstration Project – Interim Insights from Heat Pump Performance Data – Energy Systems Catapult/Department for Energy Security and Net Zero (DESNZ) 2023.

- Lowe, R et al, Final report on analysis of heat pump data from the renewable heat premium payment scheme, BEIS/ RAPID-HPC/UCL EI, 2017.

- BSRIA BG 7/2009 Heat pumps – a guidance document, BSRIA 2009.

- bit.ly/CJNov23CPD6 – accessed 4 October 2023.