Commissioning an air distribution system is the process of systematically testing and adjusting to ensure it operates as intended and meets design specifications. Without proper commissioning, ventilation and air conditioning systems can deliver poor air quality, uneven temperatures, issues with comfort, wasted energy, and potential safety issues.

In 2024, revisions took place on two key documents, one each from CIBSE and BSRIA, that provide essential – and now significantly updated – information to ensure that systems are commissionable by employing suitably rigorous methods. This CPD will focus on aspects of CIBSE Commissioning Code A: Air Distribution Systems, and outline how the CIBSE and BSRIA documents relate to each other.

The 2024 revision to CIBSE Commissioning Code A (CCA) details the process for setting to work, functionally testing, and regulating ventilation and ductwork systems. It may be employed to verify that systems meet specified air distribution requirements and operate within specified tolerances, ensuring proper levels of air quality, thermal comfort and energy efficiency.

This revision is a significant development on previous editions that originated more than 50 years ago and were last reviewed in 2016. The 2024 revision was created in collaboration with the Building Services Research and Information Association (BSRIA) and the Commissioning Specialists Association (CSA), and focuses primarily on functional testing and regulating aspects. The revisions incorporate new guidance on various specialist systems, emphasise the importance of ongoing commissioning throughout a building’s life-cycle, and address specific considerations for projects involving shell and core construction and fit-outs.

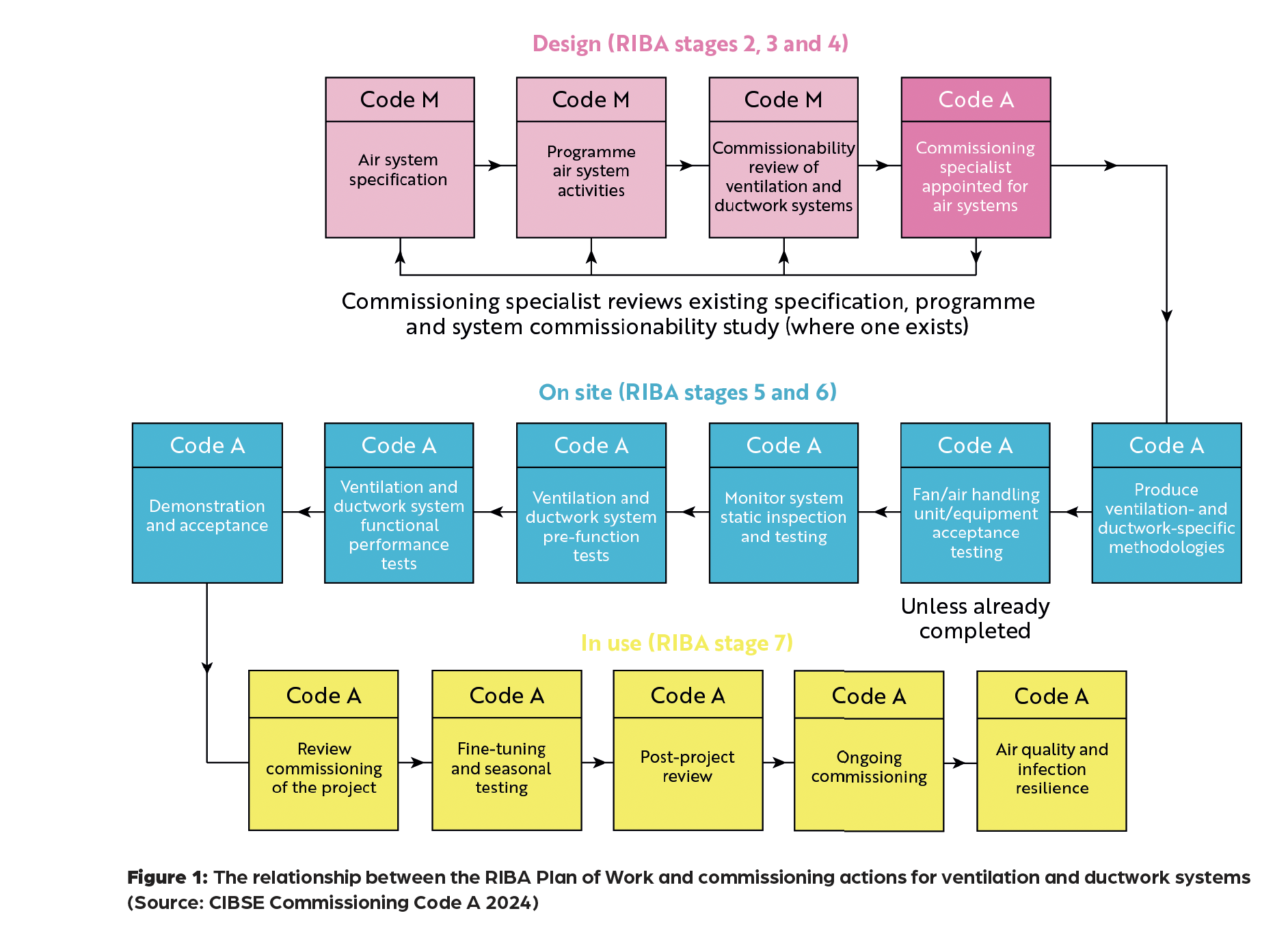

CCA majors on ventilation and ductwork specifics, while reference can be made to CIBSE Commissioning Code M: Commissioning management (2022) for the overarching commissioning management process. The suggested actions are referenced to the RIBA Plan of Work, as shown in Figure 1, and CCA clarifies which activities fall under the responsibility of the commissioning specialist and which are handled by the commissioning management team.

The newly revised BSRIA BG49 2024 (see boxout, ‘BSRIA BG49 and CIBSE Commissioning Code A relationship’) offers detailed methodologies for carrying out the functional testing and regulating procedures outlined in CCA. The collaborative development of CCA aims to provide a comprehensive and standardised approach to commissioning air distribution systems.

BSRIA BG49 and CIBSE Commissioning Code A relationship

BSRIA BG49: Commissioning Air Systems and CIBSE Commissioning Code A: Air Distribution Systems (CCA) are complementary documents that provide guidance on the commissioning of air systems in buildings. CCA sets the overarching framework and standards for commissioning air distribution systems, while BG49 provides practical guidance and methodologies for conducting the necessary functional testing and regulating procedures in accordance with those standards. BG49 suggests specific tolerances for flow-measurement results – drawing on the recommendations provided in CCA and the procedures outlined in BG49 – that, when correctly implemented, should ensure compliance with CCA.

BG49 acknowledges the importance of CCA in the commissioning process and aims to ensure alignment between the guidance published by both organisations. The documents work in tandem to ensure the proper commissioning of air systems in compliance with industry standards and the requirements of Building Regulations.

CCA 2024 has specific references to a more extensive range of air distribution systems than that of its predecessor, moving beyond the traditional focus on constant air volume (CAV) and variable air volume (VAV) systems. This version of the code also addresses the distinction between shell-and-core construction and category A and B fit-outs.

While primarily considering UK practices, CCA has global relevance and includes guidance for applications, noting that some practices or designs covered may not be common in the UK but are pertinent to international contexts.

CCA 2024 emphasises the significance of well-commissioned and maintained ventilation systems in ensuring a healthy indoor environment and mitigating infection risks. Appendix D underscores the importance of maintaining high air quality within buildings to enhance occupant wellbeing and minimise infection spread, referring to research and guidance from organisations including the Royal Academy of Engineering and CIBSE.

Ongoing testing and balancing throughout a building’s lifespan, together with continuous monitoring and adjustments, are highlighted as being key to maintaining system performance.

Well-informed decisions made at the design stage of ventilation and ductwork systems are fundamental for ensuring successful commissioning. Both BG49 and CCA emphasise the need for competent commissioning specialists to be involved early in the project. Such specialists should be trained, and possess appropriate experience and accreditation, such as that provided by the CSA.

CCA emphasises that a planned and effective working collaboration between the commissioning specialists and other parties during the planning and programming stage is essential to ensure efficient project execution. As detailed in the first of the five supporting appendices, appendix A, a comprehensive specification is essential to define system requirements, tolerances, and demonstration criteria – the requirements and procedures that must be met to prove that a ventilation and ductwork system is performing as specified.

This should be developed in collaboration with designers, contractors and commissioning specialists to ensure that the system is designed for ease of commissioning and operation. This would include taking account of factors such as accessibility of components, test points, and straight ductwork lengths to facilitate commissioning activities. The design team will need to produce system schematics and layout drawings, which indicate component arrangements and access provisions.

The commissioning specialist should review the design documentation to identify any potential challenges and ensure that the system is designed for ease of testing, measurement and adjustment. They should also work with the design team to develop a commissioning plan that outlines the specific tasks to be performed, the timing of those tasks, and the resources required.

CCA Appendix B outlines the duties and responsibilities of installers in relation to the commissioning of ventilation and ductwork systems. It emphasises the installer’s role in achieving an installation that enables successful implementation of commissioning procedures. Installers must have a thorough understanding of the system design and testing requirements, and should prioritise system cleanliness, protecting against contamination during installation, and ensure the removal of debris.

Regular inspections during and upon completion of installation determine readiness for testing. Appendix B also highlights the importance of ductwork leakage testing, which should be conducted prior to ceiling installation or the application of insulation.

CCA explains that the onsite stage of functional testing requires thorough planning and preparation. Method statements and methodologies should be prepared and approved in advance to ensure a safe and efficient testing process. In addition to the specific technical details, the Functional Testing Method Statement/Risk Assessment (often referred to as a RAMS) should outline health and safety arrangements, risk assessments and specific site procedures, and provide detailed information, including system descriptions, preparation requirements, commissioning procedures, roles and responsibilities, instrumentation, and relevant reference documents.

Pre-functional checks are essential to verify system readiness, including ductwork leakage tests and manual fire-damper operation. CCA Appendix B notes that proper documentation of test results and certification of pre-functional testing and static completion are essentially responsibilities of the installer. For significant plant items, such as air handling units (AHUs) and fans, offsite testing can be beneficial. Suitable protection should be provided for equipment that is susceptible to frost damage in cold weather conditions, and maintaining system cleanliness is paramount. CCA outlines precautions to minimise airborne detritus during initial fan startup.

Before commissioning commences, there should be a check on the readiness of the building and systems.

In CCA Appendix C, it is recommended that BG49 and materials from the CSA are referenced for details on equipment, instrumentation and flow-measuring techniques, to satisfy the needs of the various terminal types. Regular calibration of instruments is required to ensure accuracy and reliability of measurements. Guidance is provided on comparing different measurement methods when a system incorporates several terminal types, ensuring consistent evaluation of airflow rates.

Three basic ventilation and ductwork system balancing concepts are introduced in CCA: conventional CAV, VAV, and pressure differential systems, outlining their unique characteristics, functional testing, and regulating procedures. For example, for conventional CAV systems (relating to the principles of the ‘proportional balance’ method1), it emphasises the use of the ‘initial scan’ to assess system performance and to identify the ‘least favoured terminal’, and cautions against over-restricting the system.

The details of the regulation process for VAV systems are covered, acknowledging their dynamic nature and the need for a detailed methodology tailored to specific system components. It highlights the significance of adhering to manufacturer guidelines and becoming thoroughly familiar with the system. Pressure differential systems enable controlled space pressures for isolating or containing specific areas, such as operating theatres, laboratories, or escape routes where preventing undesired airflow is critical.

The pressure differential may be controlled using self-acting or automatic pressure-stabilising devices. However, it is noted that, although the initial regulation of the system will involve proportional balancing, it may be necessary to partially disrupt this balance to achieve the required pressure differentials.

Beyond the conventional systems, the code introduces more particular applications, including jet-nozzle diffusers, active chilled beams, mechanical ventilation and heat recovery (MVHR) systems, and smoke-control installations.

A comprehensive and detailed report will be needed for each tested or regulated system that would typically include, at least:

- A front sheet detailing the system, asset references, and the testing organisation

- A report sheet noting who carried out the tests, completion date, issues encountered, and any residual tasks

- Specific test sheets covering fan performance, terminal velocity readings and volume flow measurements, along with schematics of the system

- Calibration certificates for instruments used, or a reference to their central register.

Additional documentation, such as pre-functional checks, installation records and cleaning certificates, would also be incorporated as appropriate.

A key element of the functional testing and regulating process is the demonstration to a designated authority, such as the client or design team, to verify it meets specified requirements. Demonstrations should occur shortly after regulation (typically within two weeks) and align with the commissioning specification.

The completed draft report should be issued before the demonstration for review and, once agreed after the demonstrations are completed, it becomes a formal record. Acceptance of a system may require additional steps beyond the demonstration, including proving integration with other systems, confirming functionality with building management system (BMS) controls, or verifying emergency response capabilities. These activities fall outside the scope of CCA, but are within the scope of CIBSE Commissioning Code M.

Figure 2: An example of a calibrated volume flow sensor (connecting to a matched ductwork measuring point) that communicates through MODbus to the BMS. This particular unit can provide calibrated output relating to measured pressure or air velocity, and auto-zeros with a linearity (sensor deviation from a perfectly linear response) of 0.25Pa at pressures less than 100Pa (Source: CMR Controls)

CCA develops guidance for the in-use stage of ventilation and ductwork systems, including review commissioning, fine-tuning, seasonal testing, post-project review, and ongoing commissioning. This is likely to benefit from the application of BMS-connected measuring stations – such as that shown in Figure 2 – which can reliably feed back calibrated flowrate measurements throughout the operational life of the systems.

CCA stresses that the commissioning specialist’s role extends beyond functional testing and includes participation in these activities to ensure sustained optimal performance. The commissioning review process involves identifying both the successful and challenging aspects, addressing any outstanding issues, and documenting the lessons learned.

Fine-tuning and seasonal testing are important to ensure the system’s performance aligns with the design intent under varying occupancy and external climatic conditions, often in collaboration with the building’s facilities management (FM) team.

Post-project review involves evaluating the building’s overall performance against the design goals, which may include periodic revalidation of ventilation and ductwork system performance, and contributions to accreditation schemes such as Breeam and Leed. Occupant feedback, post-occupancy evaluation, and monitoring of occupancy patterns are promoted as some of the tools to inform ongoing commissioning activity.

A concise section, included as Appendix E, provides specific guidance for commissioning air distribution systems in buildings that are completed in stages. It explains the implications of staged building completion, specifically the ‘shell and core/fit-out’ approach, on the commissioning of ventilation and ductwork systems. It acknowledges the challenges posed by incomplete systems during initial stages and the need for meticulous record-keeping to ensure smooth progression of subsequent commissioning activities.

During the ‘shell and core’ phase, the commissioning specialist focuses on proving the functionality of installed equipment and demonstrating the system’s capability to deliver the designed duty. In the ‘fit-out’ phase, the emphasis shifts towards ensuring that the fit-out design adheres to the limitations imposed by the base-build system, and utilises allocated services within permissible limits.

Together, the CCA and BG49 provide a comprehensive guide for professionals involved in the commissioning process, ensuring that air distribution systems operate safely, efficiently and in compliance with industry standards and regulations. The updated 2024 editions reflect transitions in the industry, making them particularly relevant in contemporary building projects.

Both CCA and BG49 are indispensable references for commissioning air distribution systems. This article offers a very brief overview of these excellent resources and aims to encourage further exploration of their detailed guidance.

© Tim Dwyer 2025.

References:

- Harrison, E and Gibbard, N C, Balancing airflow in ventilating duct systems, Journal IHVE, 1965 –bit.ly/CJFeb25CPD1