Department of Biochemistry Credit Tim Crocker and Keith Colie

When an innovative ground source heat pump system at the University of Oxford’s Department of Earth Sciences suffered reliability issues soon after handover, in 2011, the original project team – including Hoare Lea – returned to the building to get the system working and carry out a three-year post-handover review. (See ‘All hands to the pump’, August 2013 CIBSE Journal).

Three main issues were identified: component failure, inconsistencies in the way heat meters had been ‘zeroed’, and problems with controls. After the team’s intervention, the system CO2 savings reached 24% more than predicted.

At the same time, Hoare Lea was appointed to provide technical support for the Midnight Oil project, delivered from 2010 to 2012 by the University of Oxford Estates Services’ environmental sustainability team and the Environmental Change Institute. This project aimed to reduce carbon emissions at Oxford’s 24-hour access research buildings by better managing their out-of-hours use.

Department of Earth Sciences

As a result, the university began to wonder whether it was missing other potential issues across its estate. In January 2015, Hoare Lea was employed to carry out detective work on existing university systems that may be failing to reach their full potential.

This carbon-reduction programme – led by manager Lucinda Lay – is imperative for the university, which has set a target to reduce the CO2 emissions across all functional buildings on its estate, in order to meet the requirements of the Higher Education Funding Council for England. By 2020-21, it aims to have cut 2005/06 baseline carbon emissions by 33%, which would equate to 21,773 tonnes of carbon dioxide (tCO2).

The university is currently investing more than £2m per year in carbon-reduction projects on existing buildings. To meet its target using this funding, it is seeking to average £670 per tCO2 saved.

Oxford calculated that optimisation of the BMS would cost £429 per tCO2 saved. This compared favourably with other measures; for example, solar PVs came out at £3,088, lighting at £1,300, and behaviour change at £670. (See chart on page 41 for the cost of 10 energy-saving measures).

As well as redesigning HVAC system control settings, the university and Hoare Lea have worked with occupants to address the way they interact with the buildings, and to ensure operational instructions are clear.

After calculating the amount of CO2 emitted per m2 per year for every building with a BMS system, Lay decided to tackle the biggest carbon-emitters first.

So far, upgrades to the BMS have been completed at the earth sciences and biochemistry departments, with a further nine departments lined up for 2015-16, including: the Weatherall Institute of Molecular Medicine; Saïd Business School; Old Road Campus research building; the Richard Doll building; and the Henry Wellcome buildings.

Hoare Lea’s building performance project lead, Eimear Moloney, and the University of Oxford’s head of building services, Stephen Pearson, explain how detective work uncovered operational anomalies and helped engineers to optimise HVAC systems.

By 2020-21, The University of Oxford aims to have cut 2005/06 baseline carbon emissions by 33%, which would equate to 21,773 tonnes of carbon dioxide

Department of Earth Sciences

Moloney says user interaction – and increasing occupants’ understanding of how the building systems work – were important steps in the BMS optimisation process at the 7,100m2 Department of Earth Sciences facilities, which are arranged in two wings around a common open atrium.

Moloney and the team first tackled ventilation, including heating and cooling, interviewing students to understand when they were most likely to be using the buildings. The systems were originally set to run between 9am and 5pm, but undergraduates said they used the buildings later in the day, so services were adjusted to operate between noon and 11pm.

Some time was spent analysing the underfloor heating system in the atrium. The team found that the pump for the system was running continuously, even though the hot water was switched off.

It transpired that the temperature sensor activating the underfloor heating pump had been mislabelled on the BMS. Instead the system was being controlled on a sensor in the cold-water system storage tank – indicating to the BMS by the tank’s low temperature that the atrium was constantly cold, so the pump was left running.

After the issue was discovered, Hoare Lea activated the correct sensor in the atrium, significantly reducing the run-time of the underfloor heating pump.

Having designed the original services, Hoare Lea knows the importance of a good handover to building users, and has learned that instructions should be easy to understand.

‘We are trying to get away from communicating in terms that only engineers would understand, and actually put ourselves in the heads of the users,’ says Moloney.

The word plant resonates with engineers, but to most people that means green things that grow in the ground – Stephen Pearson

She cites the example of a label on a button that operated out-of-hours ventilation. It was marked ‘plant extend’, but users failed to understand how this related to ventilation and, as a result, the button was unused.

Pearson adds: ‘The word plant resonates with engineers, but to most people that means green things that grow in the ground.

‘Although earth sciences is a well run department, with good procedures and staff inductions, you still end up with “plant extend” buttons falling into disuse because recognising what they are for is not intuitive.’

He says understanding human behaviour is a huge part of system optimisation, and the university has made an effort to stop maintenance staff manually overriding plant controls to overcome short-term problems, which inevitably creates long-term issues.

‘This is all about providing information, training and support to fitters, rather than “banning” controls from being overridden,’ says Pearson. ‘That override ignores time clocks and doesn’t compensate for outside air temperature, so the system will run like that forever. We want to get across that, if you turn a switch, there will be implications for that building’s energy bills.’

Overall, the department saved approximately £15,500 on its energy bill, and 84.5 tCO2.

Brown-bag lunches

The challenge of BMS optimisation is bringing the user along with you, says Stephen Pearson, head of building services at the University of Oxford Estates Services.

‘We have extremely busy departments, and students are motivated by saving energy,’ he says, ‘but they are also nervous about anything we might do to jeopardise their projects – especially those working in labs, because their environment is sacred.’

A lot of effort was put into ensuring departments had confidence in what they were going to do. For example, the team joined the earth sciences ‘brown bag lunches’ – a regular get-together to discuss research. ‘We saw this as an opportunity to tell everyone what we are trying to do,’ says Pearson. ‘Once we’ve done that, people engage much more – and instead of being a “pull” exercise it becomes a “push” exercise, with users demanding change rather than resisting it. When this happens you can really make some big strides.’

Every department is a separate entity responsible for its own energy bills, so the team had to keep all users and managers in the loop.

‘We cannot run departments independently of the users and facilities’ managers,’ says Pearson. ‘Unless there’s information flow, the nuances of design enabling that performance aren’t going to happen.’

Moloney adds: ‘We’ve had success with this project because of the willingness of the building managers to embrace change. Dave Muller (biochemistry), Ashleigh Hewson (earth sciences) and Roger Essex (Saïd Business School) have been critical to its success.’

Department of Biochemistry

The Hawkins Brown-designed biochemistry building was completed in 2006, and is the fifth-largest emitter of carbon dioxide in the university’s portfolio.

After the university’s and Hoare Lea’s intervention – which included optimising the chillers, variable air volume units (VAVs), and the atrium and bioinformatics ventilation systems – the department has saved approximately £33,815 and 185 tCO2 – or 5.8% on its annual emissions.

Department of Biochemistry's atrium

Credit Tim Crocker and Keith Colie

The chiller plant has its own internal controls, running at 6/12°C. The plant sequencing was inefficient, however, with both chillers running almost continuously. The team made changes to the controls, which meant the second chiller only operated when the lead chiller had reached 100% load. They also optimised frost-protection controls and run-on times of the shunt pumps. In total, the reconfigured chiller controls saved £4,000 and 18 tCO2 per year.

Overnight setback of VAVs in laboratories and write-up areas was another major carbon saver for the department. Because the building had been designed to operate 24 hours a day, all the spaces were conditioned at all times, regardless of occupation. Although controls were demand-led, investigations also uncovered an excess of conditioning.

Each lab has an associated write-up area, connected to a large atrium, and because these spaces had a secondary source of conditioned ventilation, the team reduced the flow rate from the VAVs to the write-up areas to 0 l/s during the low-occupancy period between 8pm and 8am, saving £20,500 and 105 tCO2. A CO2 sensor was installed so the space could be closely monitored, and there has been no impact on conditions to date.

Moloney believes even more can be saved, however: ‘The VAV boxes have their own controls, so we cannot change parameters through the BMS. To get the changes made, we had to have the right people on site, doing things manually. But some changes seem to have made no difference. Even though the BMS is saying a damper is closed, we can see it is open. The signal is not getting to it, so we have to keep monitoring and making changes.’

The team then addressed the ventilation in the atrium, which – aided by high-level extract fans – uses the stack effect to heat the building and reject unwanted heat. The incoming air comes via the undercroft, which has a 120kW heater battery designed continuously to supply the atrium with air at 19°C.

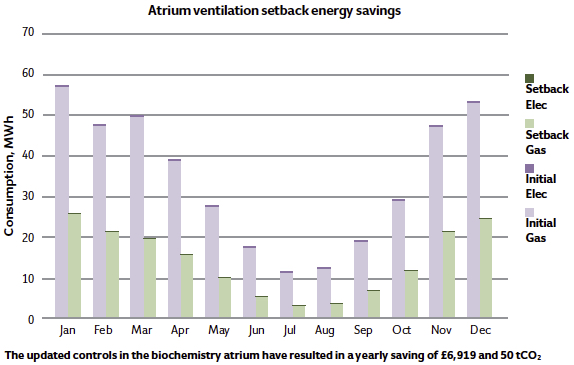

Although installed for a valid reason, Moloney says occupancy levels in the atrium did not warrant 24-hour heating. The team updated the controls so the system turned off at night, making a yearly saving of about £7,000 and 50 tCO2 (see graph, below). ‘Although a small win, it was easy to do, and we looked at it because we were hungry for more savings,’ says Moloney.

Finally, the bioinformatics room had been designed to serve a heavy IT load, but was being used as a typical office. As a result, the existing ventilation system, which comprised two large wall-mounted air conditioning units, 26 floor fan units, and central air handling units, was over-specified. The team’s decision to disable one air conditioning unit and 13 floor fans, resulted in annual savings of £1,860 and 10 tCO2.

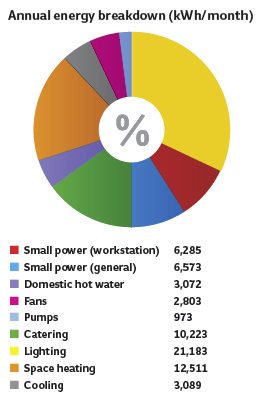

System optimisation implemented at the biochemistry department resulted in an overall CO2 reduction of 185 tonnes, shaving £33,000 off its £570,000 annual energy bill.

Saïd Business School

Saïd Business School

Conditioned ventilation of the five large lecture theatres at the Saïd Business School is one of its biggest energy consumers.

A lack of integration between the room-booking system and the BMS is common in many teaching spaces, and Saïd Business School is no different: ventilation has been set to run continuously from 7am to 11pm, regardless of whether the rooms are occupied. Changes to air flows can only be made manually, however, because the rooms are booked on an ad hoc basis. The brief when the school was constructed, in 2005, was to ensure the spaces were readily available for last-minute meetings. Since then, technology has moved on and the team believes it may now be possible to join the Trend BMS with the room-booking system.

Booking data for 2014 indicates the air-handling units in the five rooms were on for 5,000 hours, even though they were occupied for only 1,400 of these. This is equivalent to 100 tonnes of CO2 potentially being wasted.

A similar situation has been tackled at Imperial College London, where the head of IT has written software to connect the BMS with its internal booking system. Hoare Lea – working with John Matthews, head of BMS at the University of Oxford, ABEC Controls, and the Saïd Business School – is hoping to apply this solution in Oxford. ‘If it works, it could be replicated across the university,’ says Moloney.

Forward thinking

University of Oxford Estates Services has significantly benefited from continuing appointments beyond practical completion, and now requires all major capital projects to undergo a form of seasonal commissioning.

It has extended appointments to three years for every new building, to optimise systems according to users’ needs.

Lay says: ‘We want to encourage capital teams to build significantly longer post-occupancy into their budgets, so buildings are not left to run themselves for years without any optimisation.’

Moloney adds: ‘One of the arguments we come up against from clients is that they have already paid for a building that works. But that’s not right. Clients have paid for a building that complies with a set of arbitrary conditions, which often have very little basis in reality. Every building is a prototype and it needs to be seen as such. It’s not going to be perfect from day one. There will always be spaces that get used for something else – so you end up ventilating a storeroom – or grilles that people put books against.’

Lay says the university is on track to reach 53% of its target by the end of 2016. Its BMS optimisation programme has begun to address inefficiencies and will now be

complemented by new buildings that are fine-tuned for 36 months post handover.

Universities are notoriously competitive (just ask Jeremy Paxman) and other institutions will no doubt be following Oxford’s HVAC optimisation project with interest. King’s College London is another enlightened university; its use of BMS optimisation software from CIBSE award-winner Demand Logic has helped it save £400,000 per year.