While most of us would much prefer to be sunning ourselves on a beach, exploring snow-topped mountains, or simply strolling in our local park, we typically spend up to 90% of our lives indoors.

As building services engineers and designers, we take pride in creating exemplary environments for living and working. We often excel in the fields of daylight, ventilation, and visual and thermal comfort, yet the current political hot potato – namely, the failings of our government to tackle illegal air pollution – has proved a problem for us to solve.

How many of us are familiar with pages 33 and 43 of Approved Document F? The performance criteria for dwellings – also applicable to offices – states that exposure to nitrogen dioxide (NO2) should not exceed 288 μg/m over a one-hour average, and 40 μg/m over a long-term average. More importantly, how many of us know that outdoor ambient NO2 levels in many of our cities are often four times above this?

NO2 is directly attributable to 6,000 deaths annually in London alone1. As discussion of these issues moves further into the public domain, forward-thinking engineers are faced with the choice of tackling the problem or leaving ourselves open to potential liability claims.

As a nation, we are slowly waking up to the fact that, in our cities, ‘fresh air’ supplies are often far from fresh. As an industry, we need to recognise this and spread the word.

To tackle the problem, government and local authority focus has, until recently, been on reducing harmful emissions of NO2 and the equally hazardous particulate matter (PM)2.5 at source, and encouraging green infrastructure. Should current policy and the introduction of ultra-low-emission zones (ULEZ) progress, it is unlikely that we will achieve the target legal limits for outdoor air in our cities until 2021 – and it is proven that green infrastructure is far less efficient than mechanical filtration solutions when it comes to improving the quality of our indoor air.

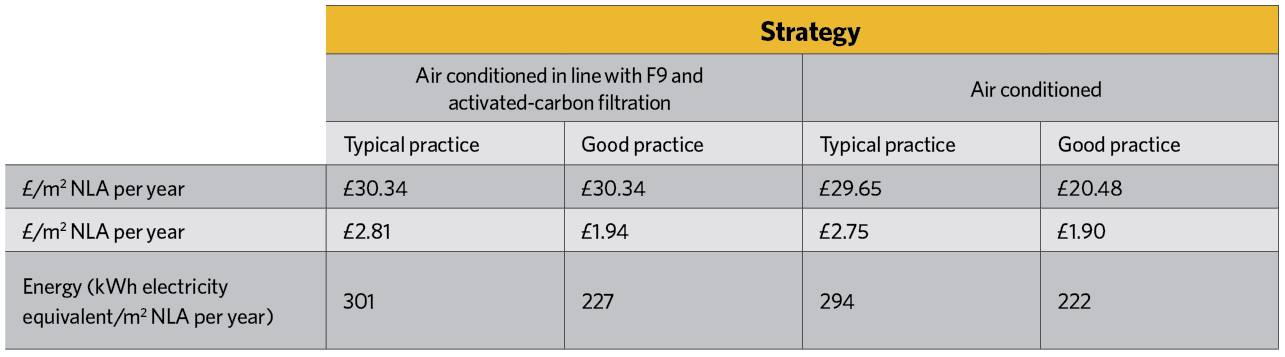

Applying activated-carbon filtration in line with F9 filters to tackle PM2.5. Figures derived from 2015 Real Estate Environmental Benchmarks3

Air-quality monitoring at all stages of a project is critical, and we must work with data from a variety of sources to build up a comprehensive picture. Unfortunately, air-quality monitoring data has a huge amount of catching up to do before we can treat it as we would weather data.

Without exemplary levels of air-quality monitoring and control, there is a strong argument that natural and mixed-mode strategies may be viewed – for the foreseeable future – as a poor choice compared to full mechanical-ventilation systems with appropriate levels of filtration and purification applied.

Filtration may also help improve outdoor air quality. We can consider every building as a lung, ‘breathing in’ polluted outside air and ‘breathing out’ processed and filtered indoor air of an improved quality – albeit with additional carbon dioxide (CO2), total volatile organic compounds (TVOCs) and other internally sourced pollutants. As a couple of dramatic examples, if designers of Heathrow’s new terminal for the third runway install appropriate levels of filtration, then the volume of air ‘scrubbed’ clean could be up to 20 times more than the volume of air associated with the ground exhaust emissions of the 600 daily flights from the terminal. Also, if every retail space in Oxford Street was to install an activated carbon filter within its ventilation system, it would be equivalent to the air-cleaning capability of planting green infrastructure over an area the size of Hyde Park.

So why aren’t we applying such filtration technology on a grander scale? It is a question of air-quality compliance and health versus energy compliance, and the associated cost.

Where careful positioning of our fresh air intakes is not sufficient, BSEN 13799:2007 recommends installing activated carbon filters to remove NO2; these are also 90% effective at removing sulphur dioxide (SO2). Used alongside F9 classified filters to remove PM2.5 and PM10, the impact of such filtration – in terms of associated pressure drop – is a major consideration for engineers, particularly when retrofitting within an existing system.

Engineers can either tackle the problem or leave ourselves open to liability claims

An increase in specific fan power is unavoidable and, when it comes to designing energy efficient mechanical ventilation, there is very little we can do to compensate for unusually high pressure drops in a well-designed and installed system. The other consideration we have is cost, in terms of energy, installation and maintenance.

Replacement activated-carbon filter costs are approximately 40-60% of the filtration unit value. While some manufacturers are claiming their filters will last up to three years, we are more inclined to believe that a typical filter, installed in an area of poor air quality, will last around six to 12 months. This can soon become a considerable cost, and schools and hospitals – where these levels of filtration are most required – may be hardest hit.

The impact of energy costs is less of a concern. Where closer comfort control is valued and a mechanical strategy has been adopted, the associated energy costs of installing appropriate filtration are minimal.

The current market trend for health and wellbeing, within our industry – and on a wider scale – is impossible to ignore. Coupled with a significant drop in the take-up of renewable technologies on construction projects in 20162 (admittedly associated with cuts in funding), this suggests consumers and building occupants value their own health and wellbeing above energy savings. The appropriate levels of filtration and air purification are costs we must not devalue or ignore.

References:

- Understanding the health impacts of air pollution in London, Kings College London

- Glennigans, 2016

- Data developed from 2015 Real estate environmental benchmarks, Better Building Partnership

Pete Carvell and Mohamad Tabatabaee are associate engineers at Battle McCarthy