After the tragic events at Grenfell, there is an increased emphasis on improving fire safety and, understandably, engineers are looking for technology that reliably reduces fire risk.

Through 2018 to 2019, arc fault detection devices (AFDDs) entered the awareness of electrical engineers and became a recommendation of The IET Wiring Regulations 18th Edition (BS 7671:2018), effective January 2019.

Building on that, the Draft for Public Comment (DPC) for the IET Wiring Regulations 18th Edition Amendment 2 (now closed for comments) proposes a general mandate for the use of AFDDs for most 230V AC circuits.

Development of a series arc fault within a cable sample

The decision about whether to follow this recommendation tends to turn on legal and commercial pressure because of AFDDs being recommended by a British Standard. But what are the technical facts and how effective are AFDDs in reducing the incidence of electrical fires. The following analysis is supported by research and experimentation by the author.

What is an AFDD and how does it work?

IEC 60050 International Electrotechnical Vocabulary defines an AFDD as a: ‘device intended to mitigate the effects of arc faults by disconnecting the circuit when an arc fault is detected.’

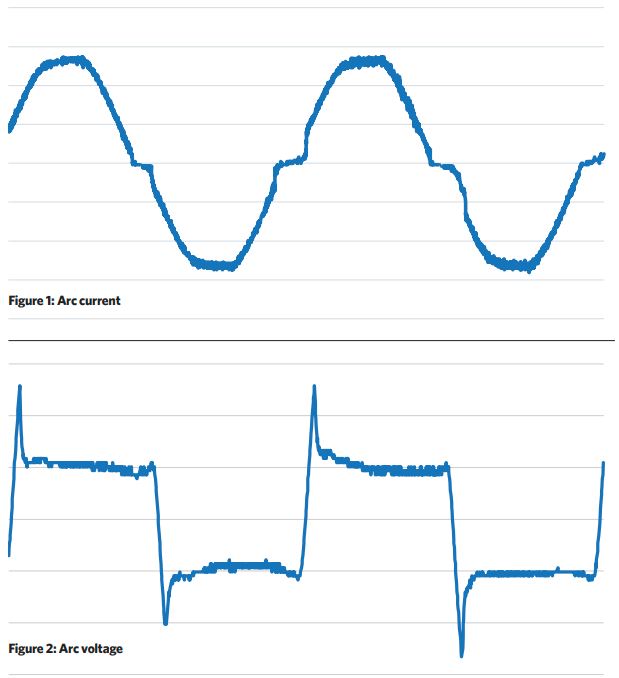

The alternating current waveform is ordinarily sinusoidal, cycling at 50Hz (Figure 1). However, arcing distorts the usually smooth sinusoidal waveform, which becomes ‘shouldered’. The shouldering is down to the striking and extinguishing of individual arcs as the voltage wave moves through the zero crossing point (the point where the instantaneous voltage is zero). The arc voltage, the voltage across the spark gap, is also distorted according to the change in impedance (Figure 2).

Such wave distortion and high-frequency noise caused by arcing are parameters that an AFDD uses to identify an arc fault.

What is an arc fault?

IEC 60050 defines an arc fault as a ‘dangerous unintentional arc’. This is in contrast to arcs that are commonly caused by switches and electric motors through break/make actions, and referred to as ‘contact arcing’. These are not dangerous, as they are considered in the design of the equipment.

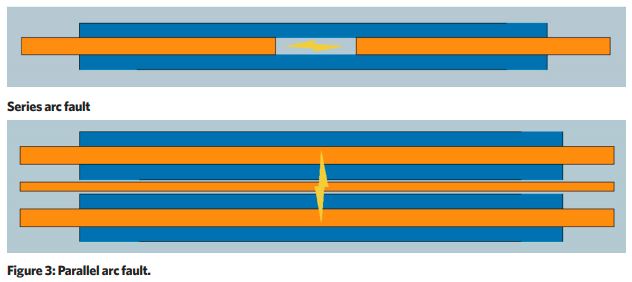

Arc faults are further categorised as being series or parallel, depending on whether the arc fault occurs in series with the supply or parallel to it.

As parallel arc faults occur between discrete conductors, they usually draw fault currents well in excess of the normal load current (Figure 3). For that reason, parallel arcing can be detected by traditional protective devices.

Series arc faults do not give rise to a fault current and, consequently, are normally considered the most problematic, because they have potential to cause ignition but are not reliably detected by traditional protective devices. Nevertheless, series arc faults emit significant amounts of energy and are capable of igniting cables and nearby materials.

What causes an arc fault?

Arcing requires a gas-filled gap (spark gap) to exist between conductors, such as a broken conductor with air filling the gap between the separated conductor ends.

‘Stable arcing’, as would be considered dangerous, is very difficult to bring about at voltages of around 230V (root mean square) – the nominal single-phase to earth voltage in the UK. Paschen’s Law indicates that, for such low voltages, the spark-gap distance over which arcing could occur is tiny, at around 7.5μm.

The factor that enables arcing over longer distances and at lower voltages is the presence of carbon at the fault zone. Carbon is a material with thermionic properties, so, when it is heated, it causes the ionisation of the adjacent air, which lowers the voltage at which dielectric breakdown can occur. It is no coincidence that the AFDD product standard (BS EN 62606) uses carbonised polyvinylchloride (PVC) electrical insulation to create arc faults for the verification of AFDD products.

Through experimentation, I found that – with charred PVC close to the fault zone – it was possible to generate arc faults in PVC-insulated twin and earth cabling. By contrast, cross-linked polyethylene does not form char and, consequently, prevented arcing.

Is an arc fault a realistic fault mode?

To sufficiently char PVC insulation to a point where it was conducive to an arc fault, it was necessary for me to condition specially prepared cable samples using a high voltage (around 15 kV). Conditioning resulted in discharges internally to the cable and intense heat at the fault zone that thermally decomposed PVC insulation.

It is difficult to see how similar carbonisation could occur in a realistic scenario without the destruction of the cable because of an external fire. Arc damage to live conductors is a possible outcome of a fire involving cabling, but that is the effect of a fire rather than being the cause of a fire.

While speculation exists regarding the causation and rate of incidence of arc faults within domestic installations, my research and experimentation indicates that arc faults constitute a relatively narrow niche within the band of electrical fault modes.

In reference to being causal to electrical fires, there is no reliable proof that arc faults occur with any significant regularity and it is possible that their rate of incidence is negligible. On that basis, arc faults appear to be a relatively unrealistic fault mode.

Do AFDDs work?

Evidence of their real-world benefit appears absent. To test whether AFDDs could prevent ignition because of an arc fault, I carried out a series of experiments that used the same principles as the AFDD standard uses in the verification of AFDD products. Using specially conditioned cable samples, I confirmed that, in most cases, AFDDs could detect series arc faults sufficiently quickly to avoid an ignition.

Series arc faults are normally considered the most problematic because they have potential to cause ignition but are not reliably detected

AFDDs were also proven to be more effective at detecting series arc faults than circuit breakers with residual current detection – for example, residual current breakers with over-current (RCBOs). However, RCBOs were also successful in some cases.

While I confirmed the lower threshold of AFDD sensitivity (2.5Amps), I found that arc faults of around 1Amp were not detected. Secondary research also confirms that arc faults of 1.7Amps, and possibly lower, are viable sources of ignition.

While exploring different electrode types, it was noted that where the breakdown voltage was significantly reduced by using carbon rods, the AFDD’s detection of arc faults became unreliable.

So, it can be said that AFDDs work reasonably well at identifying arc faults that accord with the fault conditions assumed by the product standard, but they do not prevent all ignitions caused by arc faults.

Will AFDDs reduce the number of electrical fires?

Fire statistics, such as those published by the Home Office, are not sufficiently granular to show any influence from arc faults, and it appears there is little evidence to support AFDDs having much effect on fire statistics. As pointed out earlier, an AFDD will not prevent all ignitions caused by arc faults. Consequently, it is my view that they are not likely to be effective in reducing the incidence of electrical fires.

So, what now?

Clearly, electrical fires remain a concern worthy of our focus. The spectrum of causation to electrical fires is broad, and includes equipment connected to an installation’s fixed wiring system. So, for a strategy to reduce the incidence of electrical fires, it should focus on regular inspection and testing, such that – as much as possible – faults are identified before they evolve into fires.

Making such verification work mandatory for all installations in the built environment would be a reasonable measure to reduce the incidence of electrical fires. Legislation requiring this regular verification already exists, including Electrical safety standards in the private rented sector (England) Regulations 2020’, so its scope could be broadened to include private rented, social housing and owner-occupied housing.

About the author

Kenelm Hoare MCIBSE is a senior associate at Hoare Lea