The façade at 69 Park Lane, Croydon, was the subject of the embodied energy analysis

According to a 2019 study by the World Green Building Council, buildings are responsible for 39% of global energy-related carbon emissions.

A further study by the World Business Council for Sustainable Development in 2021 found that a façade can contribute up to 31% of the total embodied carbon of a building.

To advocate for a better understanding of the environmental impact of façade designs, the Centre for Window and Cladding Technology (CWCT) launched a methodology for embodied carbon calculation of façades (see bit.ly/CJCWCTMeth).

As façade designers, engineers and consultants, we play an important role in the construction of the façade, providing advice and assumptions about façade design. Cutting carbon emissions while achieving better performance in façade is an important part of this process.

In 2017, Patrick Ryan Associates was involved in the 69 Park Lane, Croydon, project. We acted as the façade consultants during RIBA design stages 3, 4 and 5 for the total refurbishment and recladding of the whole curtain wall façade. The decision was made to maintain the original curtain wall steel frame, built in the 1980s, and replace the vision modules and spandrel panels.

This article evaluates the cost implications and embodied carbon reduction of the choices made following CWCT’s guidance published in September of 2022. We also analysed the environmental impact and cost implications if a full replacement of the entire curtain wall system had taken place.

The whole life-cycle of a façade is divided into five stages: product stage, construction process, in use, end of life, and benefits and loads beyond the building life-cycle, as illustrated in the CWCT methodology.

Representative area and assumptions

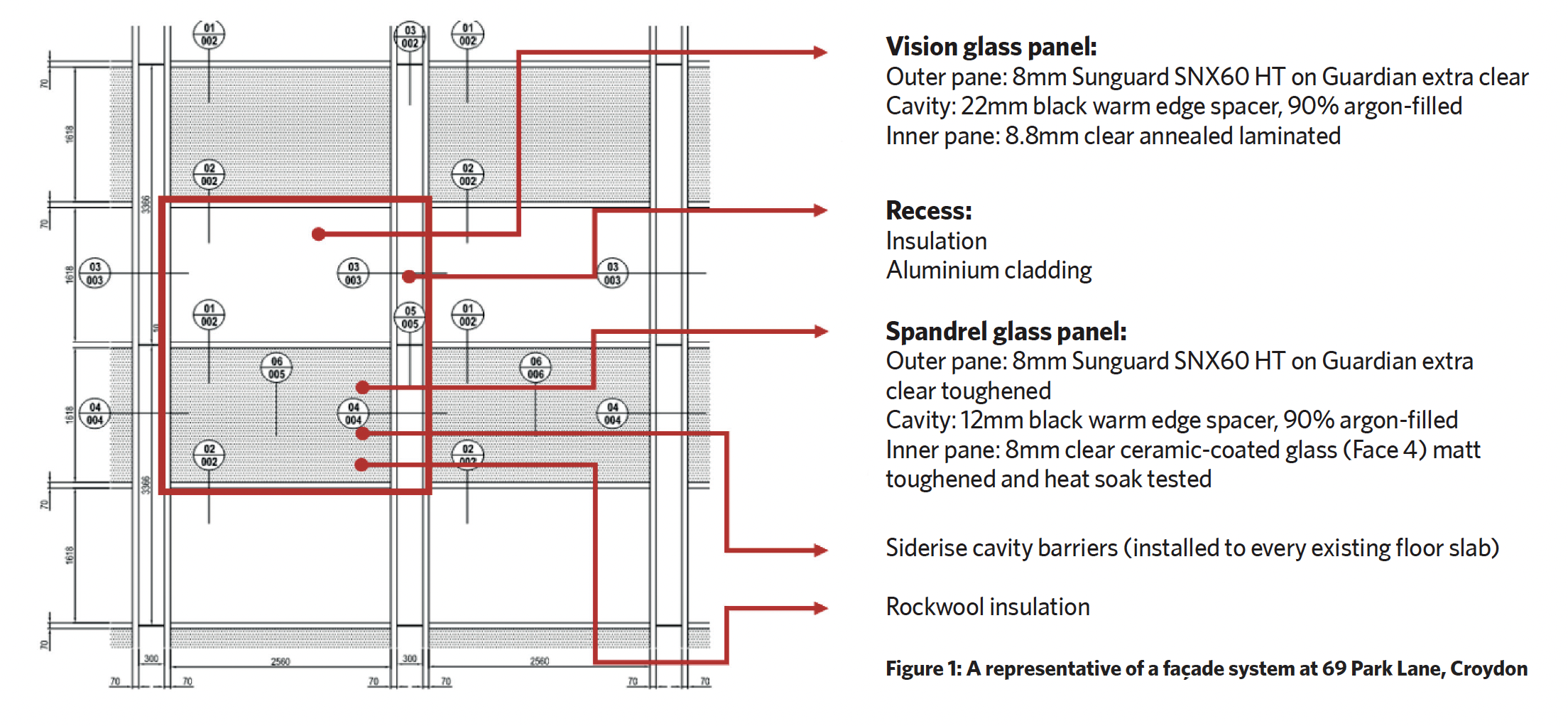

To assess the embodied carbon, a representative area of the buildings façade system was selected. The total embodied carbon of a project can be assessed by multiplying the results of each façade system, referring to the methodology.

After finding a representative area (see Figure 1), some key assumptions are made:

- Representative area (bay study) A: 3m x 3.376m = 10.128m2 FSA

- Façade surface area (FSA) = 6,680m2

- Gross internal area (GIA) = 7,500m2

- Façade form factor (FFF) = 0.89

- Reference study period (RSP): 60 years

- Raw materials procurement: Europe

- Manufacturers’ location: London

- Factory: London

- Distance between factory and site: six miles

- Site: Croydon, London

Partial vs full replacement

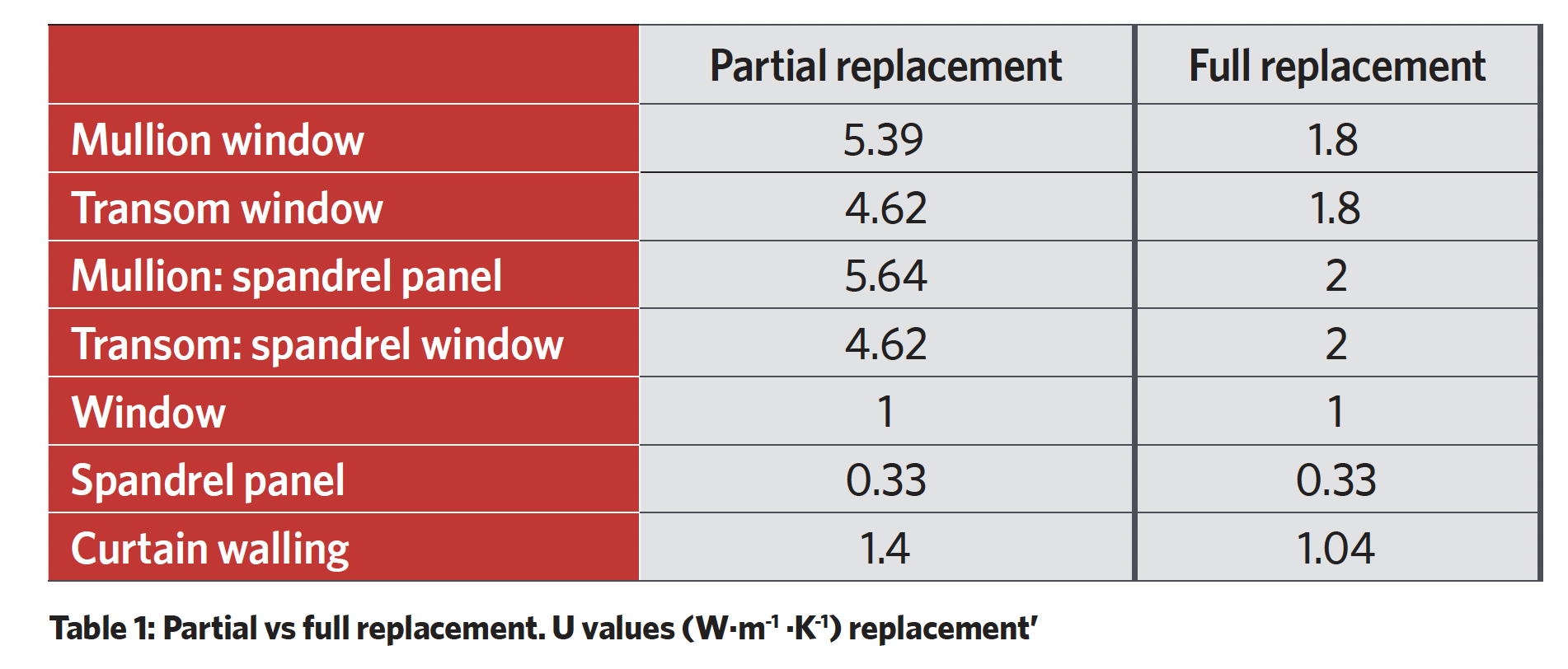

Two separate scenarios were studied and analysed for the purposes of this case study: partial replacement – the curtain wall mullions, transoms and bracketry will remain in situ; full replacement – the existing curtain wall is to be replaced in its entirety. Thermal calculations were carried out at an early stage to ensure the design team complied with Approved Document Part L in both scenarios. The U-values achieved have been highlighted in Table 1.

Results

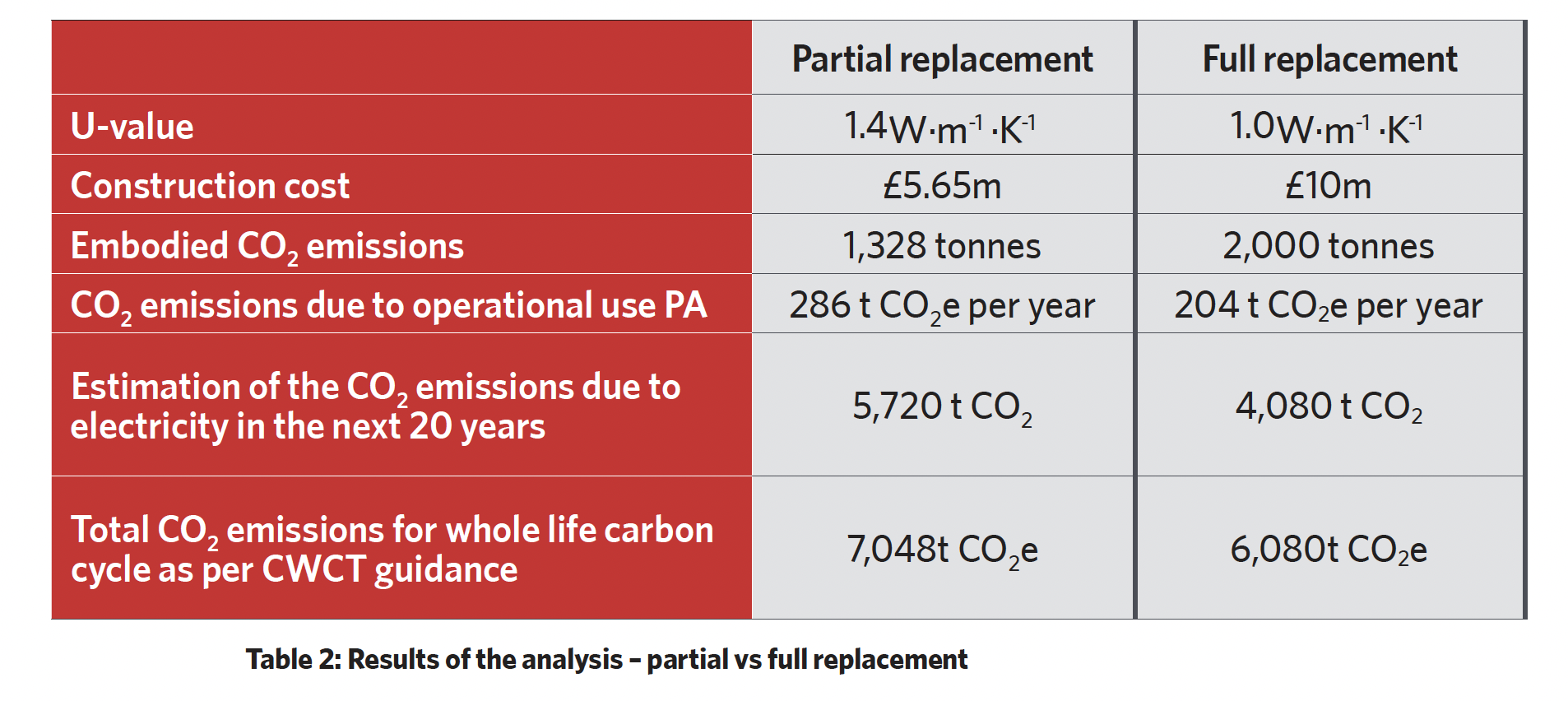

The results are summarised in Table 2.

The embodied carbon emissions for product stage and construction process (A1-A5) in the partial replacement option are 50% lower than for a full replacement. There is also a considerable cost saving, with the partial replacement being nearly half the cost of the full replacement. However, the picture changes when operational carbon savings are taken into account. The full replacement solution improves the U-values by 40%, and reduces carbon emissions from operational energy use by a third annually.

Over a 20-year period the reduction in carbon emissions because of a better-performing façade in the full-replacement option more than compensates for the higher embodied carbon emissions – 6,080T CO2e vs 7,048T CO2e.

- Anri Doda is an associate and Jill Wang a façade engineer at Patrick Ryan Associates