The Port of London Authority building, which houses the energy station

The façades of the Port of London Authority building and its neighbour The Central Cold Storage, built to hold animal carcasses for Smithfield meat market opposite, stand as a reminder of London’s commercial past. Now behind these venerable walls is a state-of-the-art energy centre that includes an innovative heat pump and borehole solution, which is claimed to cut the carbon emissions associated with heating and cooling by up to 50%.

The energy centre, owned and run by E.ON, is the latest development on a site where power was first generated in 1893. Back then, when electric power was still in its infancy, the Cold Storage building housed one of London’s first coal-fired power stations, built to power the market and its refrigerators and purchased by the City of London.

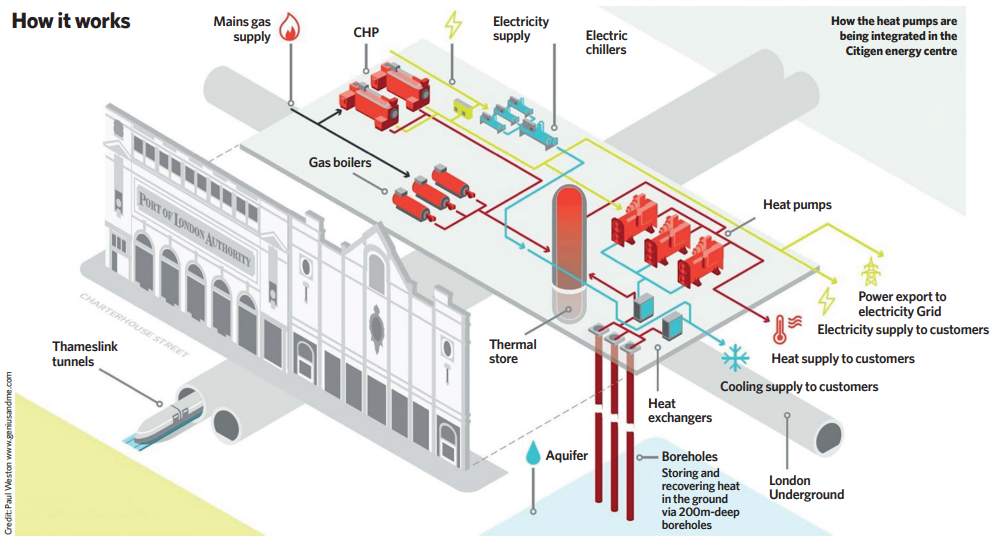

A century after it first started to produce power, the power station now has two combined heat and power (CHP) engines and two absorption chillers, which together form a centralised energy centre capable of providing up to 39GWh of electricity, 40GWh of heat energy and 7GWh of cooling per year for the corporation’s buildings in the City.

In 2013, and now known as Citigen, its two 16MW dual-fuel (gas/diesel) CHP engines were replaced by two new, smaller and more efficient 4.3MW gas-reciprocating CHP engines, as part of a £27m investment programme. The energy centre’s three, 3MW oil-fired back-up boilers were also converted to run on gas, while a 320m3, 50m-high thermal store, which can store up to 8MWh of heat, was installed.

‘If the heating load on the network is larger than 9MW, the boilers will kick in as top-up,’ explains Leke Oluwole, general manager of the Citigen district energy scheme. ‘In a normal year, 92% of the heat is reclaimed from the CHP, with an 8% contribution from the boilers.’

Three, 1.1MW low-voltage screw chillers, and a 3MW high-voltage screw chiller, were installed to replace the absorption chillers mentioned above. The low-grade heat rejected by the replacement chillers was discharged to the atmosphere via eight cooling towers.

CHP engines generate high-voltage electricity to power the chillers and network pumps, with surplus power sold to the Grid or direct to customers

The final intervention was the addition of a new control room above the energy centre, to enable staff to run it and the 70 other district heating schemes operated by E.ON around the country.

The energy centre’s CHP engines generate high-voltage electricity to power the chillers and network pumps, with surplus power sold to the Grid or direct to customers via a private wire network. Heat reclaimed from the CHP engines and their exhausts is used to heat the water in the thermal store, up to a temperature of 105°C. ‘The energy centre runs 24/7 to serve the mix of residential and commercial properties on the network,’ says Oluwole.

From Smithfield, 11km of insulated pipes weave their way underground, buried beneath public roads and hidden in basements and tunnels. These also deliver heating and cooling to the City of London’s buildings, including the Guildhall, Barbican Centre, and the Museum of London.

Heat from the thermal store is carried through 6km of pipes – at a temperature of 95°C flow, 72°C return – to 27 substations, for distribution to buildings served by the plant. Seven of the substations also provide cooling; chilled water leaves the energy centre at a temperature of 6°C and returns at approximately 11°C-12°C, depending on demand.

The control room monitors Citigen and 70 other E.ON heat networks across the UK

In June 2021, E.ON announced the start of a £4m project to decarbonise the energy centre and increase its heating and cooling capacity, to help meet a growing demand. ‘We wanted to expand the network, but to do so sustainably,’ explains Oluwole.

Working with consultant Ramboll, E.ON developed a solution that incorporated three new heat pumps, ground borehole thermal storage, and heat-recovery technology into the existing energy centre. ‘We did look at other technologies, such as biogas and hydrogen, for this very congested energy centre, 7m below the ground,’ says Angelos Chatzidiakos, formerly of Ramboll but now senior solutions developer at E.ON. However, the technologies and infrastructure needed to support these options were not readily available in London.

The heat pumps complement existing CHP, boilers and electric chillers, to provide heat and chilled water as necessary. ‘We had embedded carbon within the CHPs, which are still within their payback period, so this solution allows us to make best use of the technologies we already have,’ Oluwole says.

Three Carrier AquaForce 61XWHZE heat pumps have been installed. These use a twin-rotor screw compressor and operate on ultra-low global warming potential (GWP) refrigerant R1234ze. In total, the heat pumps provide 4MW of additional heating capacity and an additional 2.8MW of cooling.

Three sources of heat used by heat pumps

- The ground boreholes will be used as a heat source for most of the year.

- The low-grade heat that had previously been wasted by Citigen, such as heat rejected from the chillers, can now be stored in the ground boreholes. This is then upgraded by the heat pumps into useful heat when required, saving cost and carbon. ‘The heat in the ground could diminish over time, so, to avoid that, we store the recovered process waste heat in the ground to keep the temperature in balance,’ says Chatzidiakos.

- The final source of heat is the cooling network itself. ‘We designed the heat pump installation in a way that allows them to be used in combined heating and cooling mode,’ explains Chatzidiakos. In this mode, the chilled water is not routed to the chillers; instead it is piped direct to the heat pumps. ‘Because the chilled water has effectively absorbed heat from buildings, if we take the chilled water return to the heat pump, we can use it as a heat source to provide heat back to the network,’ says Chatzidiakos. He adds that this is the lowest carbon mode of operation ‘because the chillers do not need to run, but heat is still being removed from the cooling network’.

Along with heat pumps, three 450mm-diameter boreholes were drilled down into the aquifer, 200m below the street. The borehole installation was key to the commercial viability of the decarbonisation works.

‘One of the challenges we face in decarbonisation is achieving a commercial rate of return; the boreholes give us the ability to tap into the Non-Domestic Renewable Heat Incentive to help bring the payback period for this project into an acceptable range for the company,’ explains Oluwole. Chatzidiakos agrees: ‘The upgrade would still work without the boreholes, but we would lose a lot of financial benefits,’ he says.

Space constraints meant the boreholes had to be drilled in the road outside the energy centre. The road is supported by a series of subterranean arched vaults with access to the basement. To reach the aquifer from the road, the boreholes had to be sleeved through the vaulted space to enable the auger to drill down 200m to the aquifer. They also need to be threaded between three rail lines under and next to the site.

Electricity generated by the CHP engines is used to power the heat pumps. Chatzidiakos says the scheme has been designed to enable three sources of heat to be used by the heat pumps: ground boreholes; low-grade from chillers and other plant; and the cooling network (see panel, ‘Sources of heat used by heat pumps’).

Whatever the source of heat, the heat pumps upgrade the energy harvested to produce hot water at 80°C. That heat can be supplied to the network, saved for future use in the thermal store, or pumped down into the boreholes for longer-term storage.

The high flow temperature of the district heating system is because the system serves legacy heating systems in buildings such as the Guildhall. ‘This is not a typical heat pump solution because we’re supplying older buildings on the network; the Guildhall, for example, requires heat at 85°C, while newer buildings on the network with underfloor heating, for example, only require heat at 45°C,’ says Oluwole.

To provide for both, the system is designed for the higher temperature demand of older buildings on the basis that temperatures can be lowered at the heat exchanger for newer buildings.

The system will be able to vary its mode of operation in combination with the thermal store, to respond to the price of power

Chatzidiakos says the optimum mode of operation, which is a trade-off between cost and carbon, is to run one CHP and the heat pumps: ‘Consuming gas to operate one CHP provides power to run the heat pump, with any surplus sold, while the heat pump can produce heat and chill to the network.’

The system’s inherent adaptability helps ensure its commercial viability over time. ‘We want to have flexibility on our networks so that if, say, the gas price goes up, we can still run the network and meet our business case,’ Chatzidiakos explains. ‘At the moment, with the gas price, it still makes commercial sense to run at least one CHP and the heat pumps, rather than run the heat pumps on their own, which we could do.’

In addition to responding to the gas price, the system will be able to vary its mode of operation in combination with the thermal store, to respond to the price of power.

The system is currently being commissioned and the boreholes’ performance tested to see just how much energy they can yield and store. The intention is to balance the heat in and out of the aquifer to maintain its temperature at 14°C. ‘We can use all of the boreholes as a heat sink or source, or we can extract heat from one and return heat to the ground through another,’ explains Oluwole.

Heat pumps could run on their own without a CHP

As part of the project, E.ON has co-sponsored a study from the universities of Birmingham and Cambridge to help gain an understanding of the impact of interaction from multiple boreholes.

‘There are no rules or regulations to establish the interaction between boreholes, particularly from boreholes on one scheme being drilled close to those on another,’ says Oluwole.

‘This project should allow Defra [the Department for Environment, Food and Rural Affairs] and the EA [Environment Agency] to put into place rules to protect the environment and to allow the provision of low carbon heat.’

Oluwole says there is currently a lot of regeneration under way around Citigen, which E.ON hopes to capitalise on. The compact nature of the district heating connection and the space saving it offers businesses is one of Citigen’s selling points in the City, where every square metre is at a premium. It frees up attractive roof space that would otherwise house air con units.

E.O N hopes more City businesses will switch to Citigen for heating and cooling

‘What you can do with a high-temperature network such as Citigen is to cascade it, using heat exchangers, to lower the temperatures – although, over time, we would be looking to lower the system temperatures,’ Oluwole adds.

For the future, E.ON is looking at the potential of adding a lower-temperature network to Citigen to serve the area to the south of the current scheme. It has already undertaken a pre-feasibility study with a view to installing a fifth-generation heat network, which will continue its work in helping make London a greener city.