The popularity of open ceilings in commercial buildings is showing no signs of abating, as designers continue to give offices the edgy, industrial look by doing away with fixed or suspended ceilings to expose the building’s inner workings.

Traditionally, a ceiling would be in place to conceal the building services – such as ductwork, pipework and wiring – and to house grilles and diffusers, as well as lighting, safety and security systems.

In addition to not having to worry about the aesthetic arrangement of the services, there is a good building services reason to have a ceiling. It plays a key role in controlling the room environment – primarily by offering a surface along which air can be evenly distributed without disturbing occupants.

The consequence of not having a ceiling can be an uncomfortable environment because of cold spots, draughts and the dumping of cold air. We often encounter these conditions where there are open ceilings, which demonstrates that a number of building services engineers are unaware of the problem, or how to fix it.

The presence of a ceiling surface allows air to flow across it evenly. This is known as the Coanda effect – named after Henri Coanda, a Romanian aerodynamics pioneer – and it occurs when airflow is closely projected to a parallel surface. A change in pressure is created at the parallel surface, which allows the airflow to ‘cling’ to it and project along that surface in an evenly distributed, and known, manner.

In building services, the Coanda effect means air will track horizontally along the ceiling after it has entered the room via diffusers. The principle behind supply air diffusers is to evenly disperse air without causing any occupant discomfort, and to keep the environment within set temperature and comfort parameters.

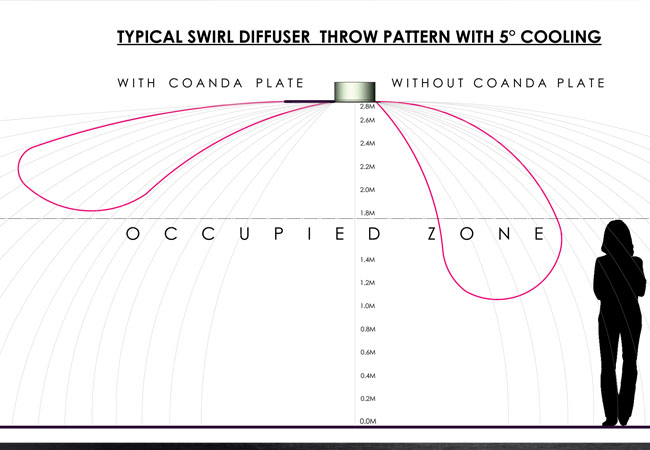

Typical swirl diffuser throw pattern with 5˚C cooling

The conditioned air will mix with the room air (mixed-flow application) and, if correctly selected, will enter the ‘occupied zone’ at the required comfort level – usually less than 0.25m.s-1 and within 1°C of room temperature for occupied spaces.

Without a suspended ceiling, there is no parallel surface on which to mount the diffusers, so there is no Coanda effect. As a result, there is no ‘fixed flow’ ventilation and the conditioned air ‘dumps’ vertically downwards, directly onto the occupants below. There is nothing for the air to ‘cling’ to.

If this issue is not addressed at the design stage occupants will complain of draughts and of feeling cold. Fortunately, there is a simple solution. To recreate the conditions necessary for the Coanda effect, a simple plate can be attached to the diffuser.

A Coanda plate is an extension of the outer flange of the diffuser. The additional surface of the plate at the point air enters the room will allow it to initially move horizontally and follow the plate. This reduces the possibility of the air dumping and allows the conditioned air to mix with the room air before entering the occupied zone.

Coanda plates work well with swirl diffusers, which are now commonly used in exposed ceilings. They also match the tubular (round) ductwork and can be connected directly without the need to provide ductwork plenum boxes. The swirl diffuser creates a 360° area directional flow pattern, allowing the air to cling to the full circumference of the Coanda plate.

As a rule of thumb, a plate that is 300mm larger than the outside flange of a diffuser should provide enough distance for the exiting air to attach to the plate, so achieving the full Coanda effect and horizontal movement of air. Interestingly, our research showed that increasing the size of the Coanda plate makes little difference little difference to the projection of air into the room and provides similar air patterns to standard diffuser data.

We carried out research to find out how big the plate had to be to create the Coanda effect and found that the 300mm ‘notional’ plate size on multiple diffusers could be reduced drastically in size. We have therefore been able to introduce smaller plates for the swirl diffuser series. We even advanced our plate diffusers to have larger ‘run-offs’ of outer flange frames, and therefore we can remove the need for additional coanda plates with the slightly larger integrated face plate designs.

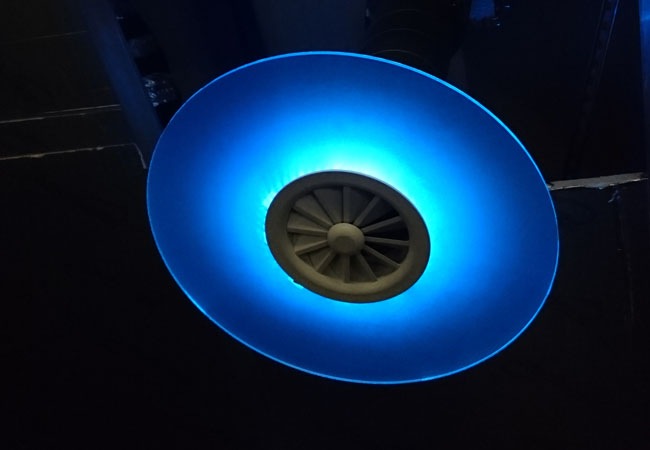

Coanda plate lit with LEDs

Coanda plates are typically manufactured from the same material as the diffuser flange and can be painted any colour. They can be of almost any material, and can be solid, opaque or even transparent. They can even be backlit with LED lighting.

We are looking to develop Coanda plates further for linear and slot diffusers. The required length of Coanda for specific linear products has been initially assessed and will allow the Coanda plates for these to be reduced below the notional 300mm length.

Our research and development department also allows us to size Coanda plates for each individual scenario or application.

Remember, when designing any open-plan ceiling system, the correct selection of diffuser must have a Coanda plate or Coanda run-off if comfort conditions are to be achieved.

■ Roy Jones is technical director at Gilberts Blackpool