For more than 50 years, the UK has relied primarily on natural gas to heat its buildings. That will need to change if the country is to transition from a reliance on fossil fuels towards low carbon energy sources, to meet its national and international commitments to tackle climate change.

It will not be easy: ‘Decarbonising heat may be the greatest challenge we face in meeting our legally binding carbon targets,’ the government warned in A Future Heat Framework for Heating Buildings, published in December last year.

Project Team

Heat network: Icax

Building estate: London South Bank University

Thermal storage: Mixergy Energy aggregator

Upside Energy Heat: Origen

Boreholes: TerraFirma Ground Investigations

Fuel Cell Calciner: Cranfield University

One way in which the challenge of delivering low carbon heat could be overcome is with a new type of district heating system called a Balanced Energy Network (BEN). Developed by Icax, working with London South Bank University (LSBU) on a project part-funded by Innovate UK, the system is being trialled on LSBU’s south-east London campus.

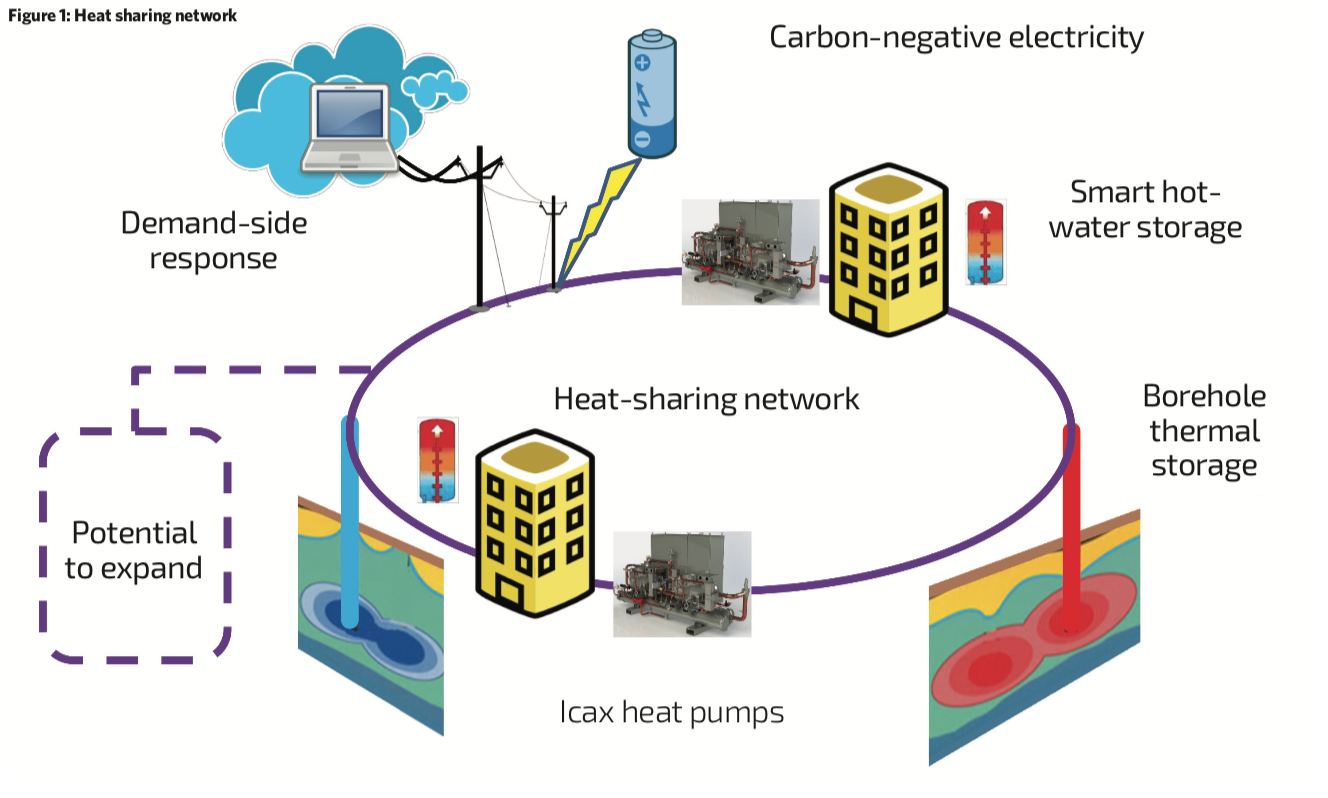

A BEN works by circulating water at ambient groundwater temperature through a piped loop to buildings on the network. Each building uses a heat pump to extract heat from the network for heating or to reject heat into it when the buildings need cooling.

Network pipes for the BEN installed at the LSBU

It does not matter where heat comes from. ‘We’re doing experiments on pulling heat out of sewers, data centres and other buildings; all we need to know is how much heat it gives us and the profile,’ says Dr Aaron Gillich, associate professor in energy and building services engineering at LSBU. ‘The more you add, the more robust the heat network – it’s like an intranet for heat.’

By managing the use of available energy, a BEN offers the efficiency benefits of a heat network without the air pollution created by gas combustion in dense urban areas.

What makes the system at LSBU unique is that, as well as transferring heat, it has been designed to respond to price signals from the electricity Grid. It can turn off electrical plant, such as heat pumps, to smooth peaks in demand or to store electricity as heat when there is a Grid surplus, for example, at night when the wind is blowing and wind farms are active.

‘Everything – from the heat pumps, the heat network, the buildings served by the system, and the thermal storage – becomes a giant distributed heat-storage device, to provide a balancing service for the Grid,’ says Gillich.

The BEN currently being trialled at LSBU serves two buildings. At the heart of the system is a network loop that distributes ambient groundwater from the London aquifer. This uses two, 110m bore holes to tap into the London chalk aquifer beneath the campus; water is abstracted through one bore hole and rejected at a lower temperature through a rejection well.

“At the heart of the BEN system is a network loop that distributes ambient groundwater from the London acquifer”

The London aquifer is a giant inter-seasonal heat store, with a temperature profile determined by the annual seasonal energy balance in the UK, plus the net energy abstracted from – or rejected to – the store by building heating and cooling. The aquifer is an excellent source of water at 14°C throughout the year, from which heat pumps draw heat and then reject water at 10°C back to the aquifer.

If any building needs cooling, its heat pumps can reject heat to the network – which, in turn, is a benefit for those buildings needing heating. This leads to a ‘heat-sharing network’ that can balance the heating and cooling needs of different buildings. In addition, heat is stored, short term, in two 10,000-litre insulated hot-water tanks, manufactured by Mixergy, which Gillich calls thermal batteries. These are heated by the heat pumps using cheap night-time electricity to allow hot water to be drawn by day, when domestic hot water is needed, or for space heating.

‘If the Grid needs to shed surplus power and we don’t have anywhere else to put it, we can store heat generated by low-priced electricity as hot water, for use later in the day,’ explains Gillich.

Heat pumps transfer the heat from the network to the buildings instead of burning fossil fuels. ‘A big part of the challenge in decarbonising heat is retrofitting buildings that have gas boilers,’ says Gillich. ‘Everybody expects 80°C temperatures coming from the gas boilers, so all of the heating circuits – such as the ones we have at LSBU – were sized for 80°C water.’

The heat pumps at LSBU were seamlessly integrated with boilers in existing plantrooms, de-risking the transition from a client perspective and allowing maximum efficiency to be achieved. They have been developed by Icax to deliver water at temperatures of up to 80°C. This allows them to be retrofitted into existing buildings –in place of, or alongside, gas boilers – without the need to modify the existing heat-distribution systems.

In addition, using the aquifer water at a constant 14°C gives the heat pumps a higher starting temperature than if air source heat pumps had been used on cold winter mornings, so they have a higher coefficient of performance (COP). Icax has developed the control systems for the heat pumps and connected the BEN system to the first demand-side management (DSM) network in the world.

There were concerns that replacing gas boilers with electric heat pumps, would raise peak electric loads. By working with energy aggregator Upside Energy, however, the BEN systems are all controlled by a set of algorithms. These tell the different systems when to turn on and off, when the system should store electricity as heat, or when to deliver cooling by moving heat to storage at optimal times.

This creates a ‘virtual energy store’, which can be combined with other systems and used to help the Grid balance supply and demand. ‘The Grid doesn’t care about something the size of our heat pumps, which each consume about 100kW of electricity and produce 300kW of heat. To make a difference to the Grid, you are talking about loads of the magnitude of 5MW, which is the reason we’re using an energy aggregator; our campus is just one piece of their portfolio,’ explains Gillich.

Using the BEN to support the Grid in this way opens the door to additional revenue streams – the biggest of which is from avoiding the electrical Grid’s Use of System charges through demand-side management.

‘The Distribution Network Operators say: “If you shift the timing of your electrical demand to avoid the 4pm to 7pm peak, then we’ll pay you X-amount of money,’ says Gillich. ‘That is what our control system is designed around – taking every single electrical component, including the heat pumps and storage tank, and making those addressable as demand-response assets.’

The BEN trial shows it is possible to retrofit low carbon heat into existing buildings

Other potential revenue streams include short-term operating reserve (STOR) and frequency response. Revenue from STOR is based on a user agreeing to reduce their demand in a matter of minutes; revenue from frequency response is based on a user being able to flex demand in a matter of seconds.

As well as turning individual electrical loads on and off in response to Grid demand, LSBU is experimenting with using the buildings themselves. ‘The more fun, experimental bit was using the buildings as demand-response assets,’ says Gillich.

LSBU doesn’t want to turn on the heat pumps between 4pm and 7pm because it is expensive. ‘We’re trialling running the temperature up to 24°C and then letting it coast back down during peak time. We’re basically taking thermal comfort in the building and making that the asset you’re selling to the Grid.’

Gillich says business models for the BEN are still being developed. The LSBU system offers an excellent platform for proving the robustness of the system and the business model.

As part of the trial, the team is also working with Origen Power and Cranfield University to incorporate a fuel cell calciner into the BEN, to give a non-intermittent way of generating electricity to power the heat pumps while removing CO2 from the atmosphere. ‘The use of the fuel cell shows that any renewable can be plugged into the BEN,’ says Gillich.

What is a fuel cell calciner?

The calciner works by feeding natural gas into a standard fuel cell to generate electricity. This process generates heat, which is used to break down limestone into lime (CaO) and pure CO2, to be used or stored underground. The lime produced can also be used in industrial processes, during which it absorbs CO2 and is converted back into calcium carbonate – the original limestone. Overall, the process is carbon negative, absorbing 800g of carbon for every kilowatt hour of electricity generated, as opposed to releasing 400g of CO2 for every kilowatt hour with conventional combustion technologies. Origen Power’s Tim Kruger suggests using the lime to counter ocean acidification. ‘You absorb about twice as much carbon dioxide when you add it to seawater as when you use it industrially,’ he says.

A big advantage of the BEN is that it is scalable. At an urban scale, BEN infrastructure allows heat networks to be delivered in small increments and expanded over time, avoiding many of the barriers that currently hinder investment in heat networks. At the national scale, any building or system linked to a BEN network becomes a distributed storage device, and offers a low-cost balancing service to the National Grid. This will help to address some of the capacity challenges that the Grid faces as fossil-fuel plants are replaced with more intermittent renewables.

“Using a BEN to support the Grid opens the door to additional revenue streams – the biggest of which is from avoiding the Use of System charges through DSM”

The trial at LSBU has successfully demonstrated the potential of BENs. ‘We had the best feedback we could possibly have had when we ran the new system – which was none at all,’ laughs Gillich. ‘It means nobody noticed because it worked exactly as the old heating system did from the end users’ perspective.’ More importantly, the trial shows that it is possible to retrofit low carbon heat into existing buildings in central London and that there is a low-cost organic approach to integrating them into future heat networks.

BEN partners are applying the technologies in other projects: Icax is deploying the network design and high-temperature heat pump in UK schemes; Origen Power is developing a 400kW fuel cell calciner; Mixergy is rolling out its thermal store on UK domestic projects; and Upside is developing a large-scale aggregation portfolio. Thanks to BEN, the future of low carbon heat is becoming a little clearer.