Credit: iStock

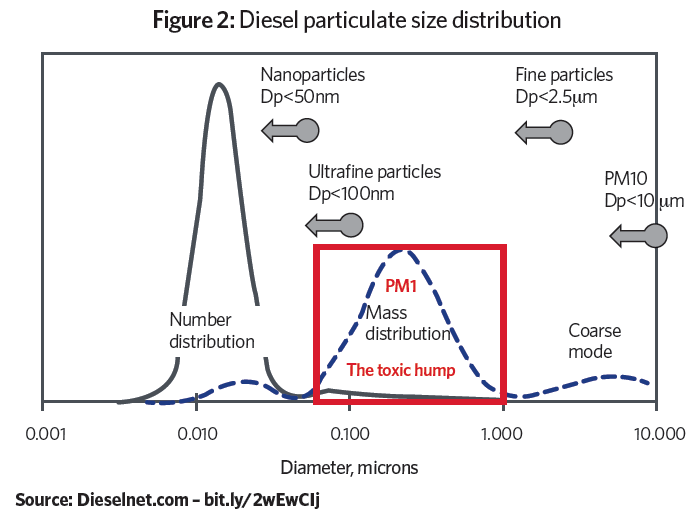

Air pollution in our cities caused by traffic emissions poses a threat to human health. Medical and scientific experts report that the PM1 fraction of airborne fine-combustion particulate matter (PM) – together with the associated nitrogen dioxide (NO2) – is the most hazardous. PM1 particles come, principally, from diesel-vehicle emissions and other combustion of fossil fuels.

The World Health Organization has classified diesel emissions as Group 1 carcinogens – the most toxic – adding that there is ‘no safe level of exposure’ for humans. A recent report from the Royal College of Physicians, Every breath we take, has also identified the threat to health of nitrogen dioxide – so ISO 10121-2:2013 gives a test method for NO2 removal filters; 90% efficiency is achievable.

PM1 particles can be absorbed into the bloodstream via the lungs. Particles below 10 micron (μm) in diameter are invisible to the human eye. The opportunity to select and use filters with a particulate matter removal efficiency (ePMx, as defined in 3.1.6 of the new standard) of ePM1 will result in improved indoor air quality (IAQ) and a reduced risk to health.

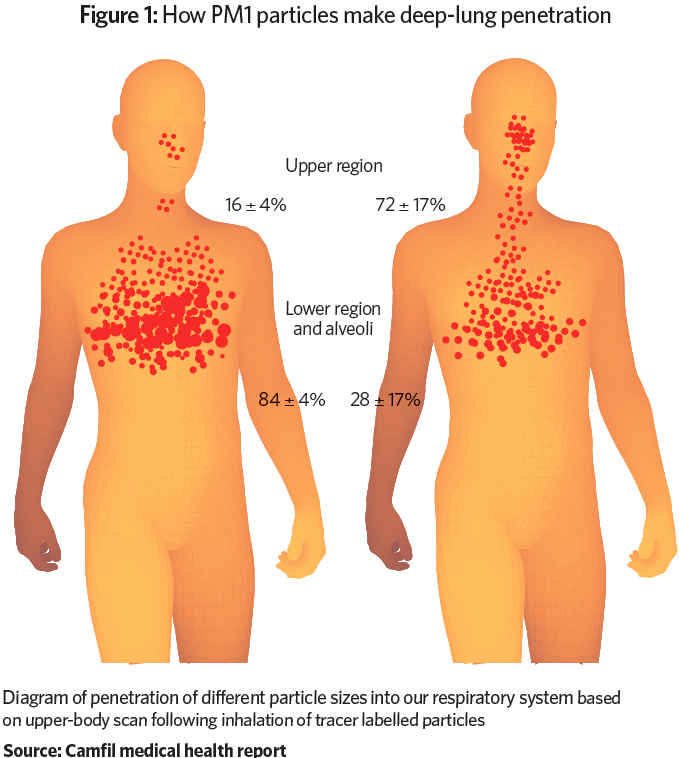

The diagrams based on body scans in Figure 1 show that the peak mass distribution of the toxic PM1 range (84%) penetrate the furthest. Those above PM1 have a much-reduced (28%) ability to penetrate a person’s lung alveoli and the bloodstream.

So ISO 16890:2016 ePM1-rated filters used to a high efficiency are recommended, to clean incoming supply air in city buildings and make it clean enough to breathe without risk to health.

Testing procedure

ISO 16890:2016 – published in December 2016 – is the new testing procedure and classification system for particle air filters used in general ventilation systems. The decision to release it was backed by all voting ISO countries, as the air-filtration industry had previously lacked a global standard. ASHRAE 52.2 dominated in the Americas, while EN 779:2012 – which will be withdrawn from the UK in June 2018 – prevailed in Europe. In Asia and the Middle East, both standards were used side by side, along with those from individual countries such as Japan and China.

How is the standard constructed?

It has four parts:

- Technical specifications, requirements and the classification system

- Measurement of fractional efficiency

- Determination of dust arrestance and airflow resistance versus the mass of test dust

- The conditioning method to determine the minimum fractional test efficiency.

Efficiency is tested with three different particle sizes within the 0.3μm to 10μm range, and the results are related directly to performance against PM1, PM2.5 and PM10.

A new, fine ISO dust is used for dust loading, which indicates the life of a filter and development of pressure loss. A mandatory and rigorous discharging method is employed, using an IPA vapour. Filters must achieve a minimum 50% efficiency to qualify for ePM1 and ePM2.5 classifications. Overall, there are 49 filter classifications in four groups – ePM1, ePM2.5, ePM10 and ISO Coarse. Only one classification is allowed on a product label.

Advantages

One of the most significant advantages is that the new test procedure requires filter efficiency to be measured against the fine-particle fraction PM1 – particles of one micron and smaller. This test must be done when the filter is new and unused, and it is repeated when any electrostatic charge – which could artificially enhance performance in the laboratory – has been removed from the filter. In real-life applications, electrostatic charges are lost and there is no addition to filter performance. Both the new result and the discharge result must exceed 50% minimum efficiency for the filter to be rated ePM1.

For city locations or polluted areas, ePM2.5- and ePM10-rated filters should only be used as pre-filters. The tolerance of classification efficiency is much tighter at 5% than EN779:2012.

Who benefits?

Definitely building HVAC system specifiers and end users. The standard recognises that air filters positively influence air quality – and, so, human health. ISO 16890:2016 is also more intuitive, being better aligned with real-world air pollution. For example, an ePM1 85% filter removes 85% of particles in the tested range of 0.3μm to 10μm. The public is now better informed about air-quality issues and has access to low-cost air-monitoring technology.

Global impact

Because it is applicable worldwide, there is now one test for all filter providers. This will eliminate confusion and invalid attempts to cross-reference results from different test methods. It will also remove a barrier to trade. Consider the real world of HVAC projects today; in major construction projects – such as international airports – it is not unusual for the design engineers, constructors and the airport itself all to be in different countries.

Future outlook

For the first time, there are global HVAC air-filter standards, giving laboratory-tested efficiency performance that is close to real life for PM1 particle filters and molecular gas filters. When coupled to the Eurovent A+ energy-rating system for low-energy air filters, they should make it easier to compare fully correlated and costed solutions.

New building IAQ standards and guidance will also be aligned to these air-filter test standards.

- Peter Dyment is a technical manager at Camfi