Heat networks are a key part of the government’s strategy to decarbonise heat. While they currently only provide 2% of the heat used in buildings, the Climate Change Committee estimates that around 18% of UK heat could come from heat networks by 2050, to support cost-effective delivery of carbon targets.

There are around 14,000 heat networks in the UK, but government-funded analysis over the past eight years has revealed a myriad of issues affecting performance that risk undermining the government’s goal of providing affordable, low carbon heat. To address the situation, the Department for Energy Security and Net Zero last month published a Heat Network Optimisation Guide. Targeted at consultants and specialists, it aims to standardise the performance of existing residential and mixed-use heat networks – but the principles apply to all heat networks.

‘The main purpose of this guide is to provide a standardised set of processes and approaches that anyone who is undertaking optimisation can use, with the aim of providing a standard minimum quality,’ says co-author and FairHeat lead engineer Tom Burton.

The guide complements the Heat Networks Technical Assurance Scheme (HNTAS) guidance, which – together with the CIBSE Heat Networks Code of Practice – will legally oblige heat network operators to adhere to minimum technical standards from 2025. Its objective is to identify the root of suboptimal performance and outline business cases for improvements.

16 common reasons for failure

Key failures in heat networks were identified following the review of existing systems by FairHeat. Burton says that many systems will be failing for at least one of these reasons:

- Insufficient consideration of heat network requirements at concept design stage

- Incorrect sizing

- Unnecessary complexity

- Unsuitable hydraulic arrangement

- Poor insulation specification and installation

- Poor planning and civil works for underground pipework

- Poor underground pipework installation

- Insufficient monitoring and data collection

- Inappropriate design and commissioning of consumer connection and/or heat system

- Lack of consideration given to system pressures

- Lack of consideration given to maintainability

- Poor installation and commissioning practices

- Inefficient control

- Uncontrolled network flows

- High return temperatures

- Poor water quality

Burton urges the industry to get behind the guide: ‘The more engineers and specialists there are providing operators with the information they need to improve customer experience and efficiency, then the closer we will be to providing low carbon, affordable heat to residents, and a reliable level of service.’

The guide is based on heat network investigations by FairHeat in two government programmes: Heat Network Optimisation Opportunities and the Heat Network Efficiency Scheme Demonstrator. Key performance indicators (KPIs) based on this analysis capture the underlying performance and resilience metrics of heat networks, and feature in the optimisation guide. ‘They feed into both the cost and carbon intensity of heat,’ says Burton.

Four-phase approach

The guide recommends taking a four-stage phased approach: understand; stabilise; easy wins; and continuous improvement. Once root causes have been understood, the stabilisation of a heat network should take place to improve performance and reliability, it says. Easy wins can then be carried out that have short payback times but require more planning and design.

The continuous improvement cycle is designed to enhance performance over a long period. It has four repeating stages – measure, analyse, test, and implement. Consumer heating systems have the biggest impact on performance, followed by district/communal distribution systems and energy centres, says the guide. End users are at the top of the optimisation hierarchy because their requirements dictate the minimum flow temperature at which the network can operate.

Minimising flow and return system temperatures results in the lowest possible heat losses across the entire heat network. As the minimum flow and return temperatures are largely set by dwelling equipment, they are the most important element to optimise, states the guide, which describes typical measures to stabilise the network, and lays out easy wins and continual improvements. Of key importance is stopping uncontrolled network flowrates, which can result in high pump energy consumption and higher heat losses. The three main actions to get network flow under control are: removal of network bypasses; elimination of end user bypasses; and control and/or replacement of pumps.

Often, a small proportion of dwellings are responsible for most of the flow on the network, which means it only takes a few bypassing units to have a significant effect on performance across the whole network. Poor water quality can also have a significant impact on performance.

Easy wins and continuous improvement measures include reducing flow and return temperatures. The guide says most systems are oversized, offering the potential to reduce flow temperatures and lower heat losses. To cut return temperatures, there should be a focus on the performance of system dwellings and removal of network bypasses across the system.

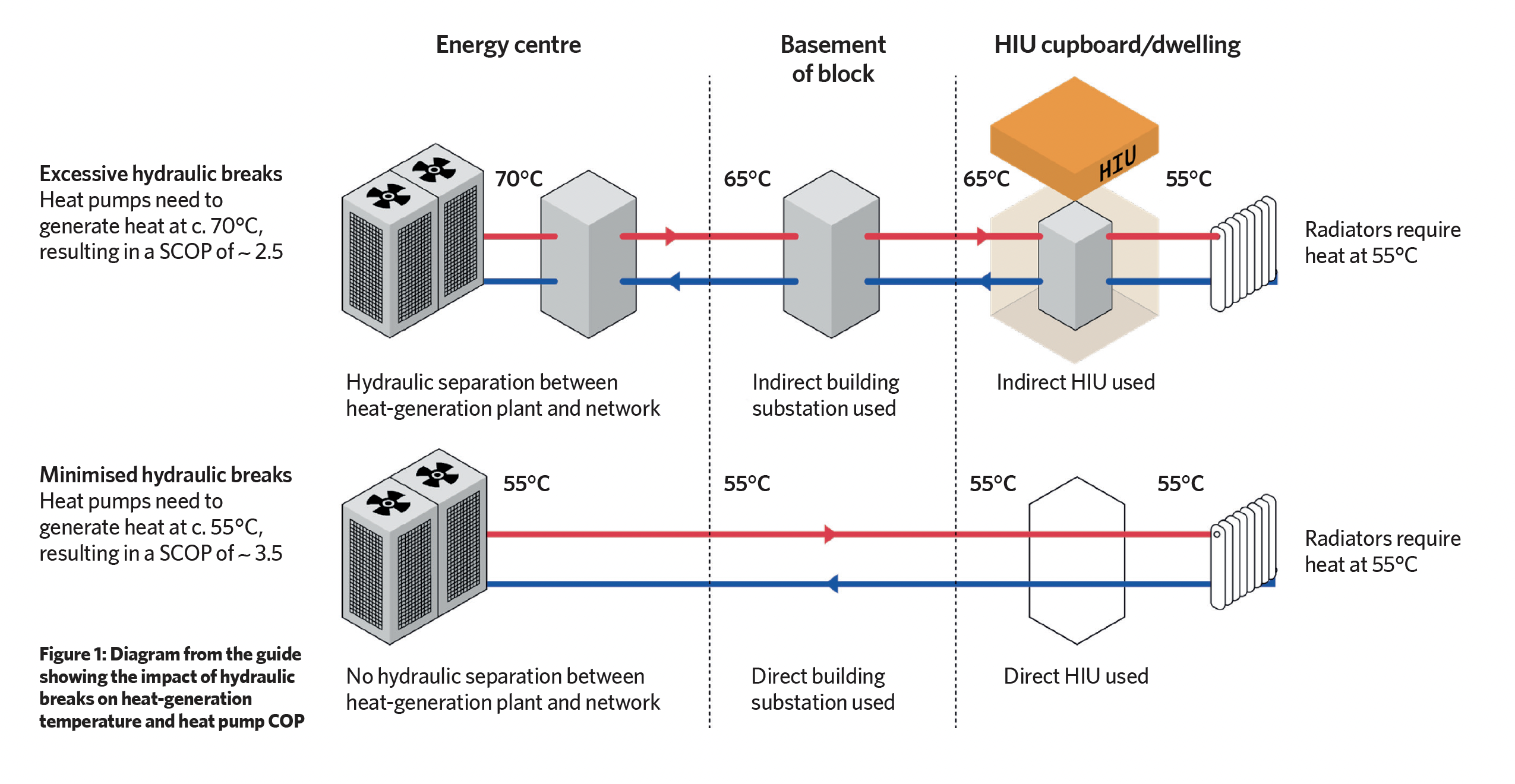

Over-complexity is a common reason for underperformance, says the guide, such as: unnecessary hydraulic separation resulting in low seasonal coefficients of performance (SCOPs – see Figure 1); separate distribution pumps for each block when one would do; and redundant equipment that has not been disconnected. It recommends a hierarchy for optimisation improvement, from repair through to recommission, upgrade/improve and, finally, replace.

There is a detailed description of the optimisation process, broken down into nine steps across three phases: initial investigation; techno-economic options appraisal; and implementation plan. There is also a pre-project phase, in which the engineer understands the client’s aims and the project scope is agreed.

The Phase 1 assessment is to gain a full qualitative understanding of system performance and issues, while Phase 2 is to gain a full quantitative understanding of them, and the impact on system performance of addressing issues. This impact is compared against initial costing to indicate the business case of potential interventions. This includes a root-cause analysis of issues and a KPI assessment of performance and potential interventions.

Phase 3 is to gain an understanding of costs, to develop a business case and implementation plan.

Key performance indicators

The guide recommends using KPIs for quantitative analysis of heat network performance using data from the building management system, heat meters and utility bills. This helps with understanding the performance of existing heat networks and evaluating the impact of improvement measures. There are KPIs for energy centre, heat network and dwelling performance, as well as for reliability, costs and carbon/air quality impact. The most important relate to heat loss, which can be compared with other networks.

For the dwelling, there are KPIs measuring overall average return temperatures, as well as figures for domestic hot water and space heating. The energy centre KPIs have a metric for heat generation efficiency, as well as flow and return temperatures. Other KPIs target flow-temperature stability, maintenance frequency, and time below minimum flow temperature, which reflect the reliability of the system for end users.

There is also a KPI for carbon intensity of heat. ‘This is very useful for operators, as they can look at the KPI numbers across portfolios and see the worst-performing systems and where to prioritise spending,’ says Burton.

Study engineers will need a minimum of two years’ experience to carry out studies

Site audits and making a business case

There is a section in the guide on conducting site audits, which are designed to determine the condition and method of operation of heat network elements. It lays out the audit process, as well as data analysis and modelling techniques that can be used to assess performance.

The section on making a business case looks at two methodologies to analyse financial impacts of potential interventions: simple payback and net present value. There is also a section on interventions that do not have a direct impact on performance, but that reduce operational risk, such as improvement in water quality. It includes a process for identifying and mitigating risks.

Knowledge requirements

For studies, the guidance defines two roles: study lead and study engineer. The study lead is accountable for the technical quality of the report, conclusions and recommendations, and should have more than five years’ experience in the heat network sector. Study engineers, with a minimum of two years’ experience, lead the onsite audit and are responsible for managing the technical and financial analysis of the optimisation study.

Template scope of works

A separate version of the optimisation guide, the Template Scope of Works, is aimed at operators. It can be used to procure an optimisation study and be appended to a tender pack, and has an outline of the process and knowledge requirements. ‘Operators can ask for a quote based on this document and anyone undertaking the work has to follow the guidance,’ says Burton.

There are also videos for operators, to help them understand the technical language and identify when heat networks are not performing..

The optimisation guide is essential for anyone operating a heat network – and not just because it will cut carbon and reduce heating bills. Burton says a form of the KPIs will be included in the mandatory HNTAS, and adds: ‘It’s likely that there will be a requirement for existing heat networks to put in a plan to get from current to compliant.’

- The guide is available at bit.ly/3O0nqDy