Credit: The Boundary

In a world reliant on rechargeable batteries, storing energy can improve the viability of renewable technologies as we strive to deliver greener buildings in healthier cities. Thermal-storage vessels are, essentially, batteries – used to heat and cool buildings – and the opportunity to integrate this concept into new and existing building designs should not be overlooked.

While thermal-storage systems are not new, the focus, generally, has been on using them for heating and cooling purposes or large industrial processes. However, they are also being used in commercial office and residential developments for heating and cooling – and, therefore, heat recovery.

The need to improve air quality and decrease the carbon impact buildings have on the environment is essential to help combat the current climate emergency. Recently proposed carbon factors have led to the use of gas within London seemingly being phased out, with ‘all electric’ buildings being favoured.

All-electric heating, particularly in colder climates, can be challenging to implement with ever decreasing rooftop plant space and limited electrical infrastructure. Air source heat pumps, for example, do not perform well in very low ambient conditions – when they are needed most – but are very efficient at high ambient temperatures.

This inherent problem can be solved with thermal storage, by producing and storing heat when ambient conditions are more favourable and using the stored heat when it’s required. Storage systems can shift loads from peak to non-peak times, reducing operating costs and improving plant efficiency. Similarities can be drawn with the daily usage cycle of a mobile phone: charging the device overnight when not in use and discharging it throughout the day as required.

Thermal storage opportunities

A thermal store is essentially a large thermal-energy battery – or, more specifically, a device to absorb or give up heat over time to heat or cool buildings. Typically, water is contained in insulated storage tanks filled with stratified chilled or low-temperature hot water. The sizing of these systems can be designed to meet a portion of short-term peak, daily, or even weekly cooling or heating loads.

The opportunity for heat recovery becomes available when chilled and hot water thermal-storage systems are linked. Cooling systems normally reject heat to atmosphere, but with hot-water thermal storage, it can be captured, and used at another time for domestic hot water and space heating.

The design and size of the tanks can allow peak loads, usually seen at the primary plant, to be reduced, allowing significant reductions in plant size. Traditionally, a building’s plant is designed to deal with peak loads that may exist for a very small portion of the year, if ever. This means the full capacity of these systems is rarely – if ever – used. Optimising plant size by using thermal-storage systems will reduce capital expenditure and make more frequent use of its available capacity.

The thermal-load profile of the building is decoupled from the operation of the heating and cooling systems, providing increased flexibility, reliability and efficiency. For a cooling-dominant building, heat-generation plant may not be required. Charging of tanks can be done during off-peak electricity tariffs, further reducing overall energy costs and payback periods.

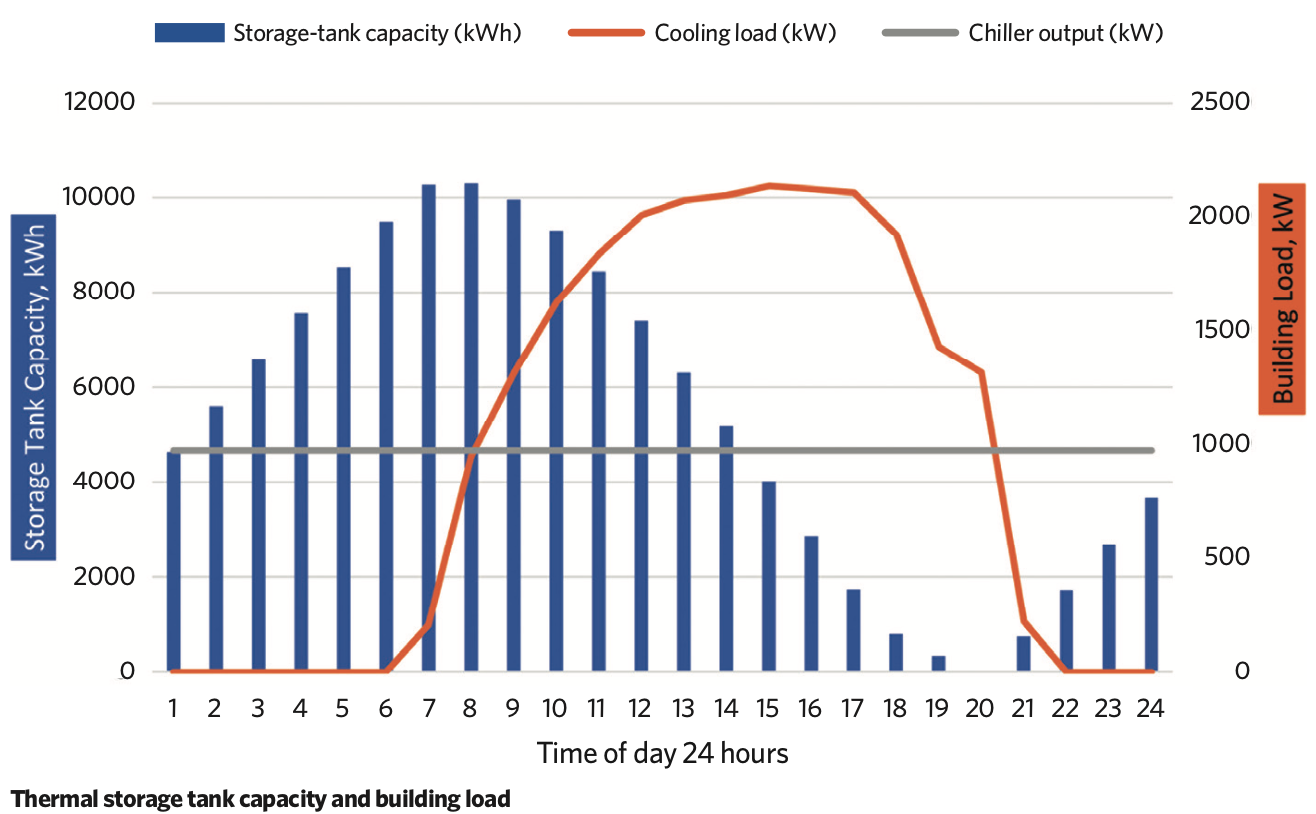

Typical thermal-storage tanks use thermal stratification, where warmer and less dense water floats atop cooler water. Chilled water is drawn from the bottom of the store and returned to the top. This is done at a very low velocity, to prevent any induced inertial effects that may mix the water and disrupt the temperature differentials. As the load from the building is decoupled from the cooling plant, chillers or heat pumps can operate at their most efficient, and may not be affected by non-favourable external conditions or the normal variable building loads. The chillers can be turned off during the warmest part of the day, despite this coinciding with the peak cooling loads.

With thermal storage, a nominal peak day can result in cooling plant operating continuously over 24 hours to charge the tank and support the peak demand. A nominal peak cooling load of a building of more than 2,000kW can be met by 1,000kW in primary cooling plant if sized appropriately. The storage system in this example will be full before the building’s normal operating hours and discharged at the end of the working day.

Water-side free cooling may be appropriate in very cold climates at normal chilled water temperatures (6°C) and in temperate climates where there is a use for chilled water at a supply temperature of 10°C or higher. Manufacturers of free cooling air cooled chillers advise that some free cooling is available once the ambient temperature falls to 3K below return chilled water temperature.

Challenges and benefits in refurb and new-builds

For efficient, high-density energy storage, large temperature differentials are required; at least 10K is desirable. Most air source heat pumps and air or water-cooled chillers cannot generate large enough temperature ranges for storage systems unless cascade arrangements are used. There is currently a very small selection of suitable products on the market that can produce efficiently the required water temperatures for storage, so refrigeration technology must adapt to support these conditions if thermal storage is to be a common solution for buildings in the future.

Phase-change materials can offer denser energy storage, but are limited and, historically, operationally unreliable. Further, very large volumes and usable space for the storage tanks are required. The spatial requirements can be challenging; usually, these tank installations require very tall tanks and huge volumes of water.

An obvious benefit of integrating thermal storage into a building’s design is that primary heating and cooling plant capacity can be reduced, thereby also reducing plant area and electrical infrastructure. Buildings can change their peak electrical demands to be more diversified, and make use of off-peak tariffs.

Millennium Bridge House

Reducing plant areas can enable more flexible rooftop designs. Take, for example, the recently approved refurbishment of Millennium Bridge House in London. Norman Disney & Young’s (NDY’s) thermal-storage design negates the need for heating or cooling plant to be roof-mounted, so allowing more than 2,500m2 of roof space to be used by the public, retail and office building tenants. The existing building’s roof offered no rooftop amenities, and all usable space was dedicated to HVAC plant. This Breeam excellent scheme – developed with Piercy&Company Architects for Angelo Gordon and Beltane Asset Management – uses large chilled and low-temperature hot-water storage tanks, located in the existing basement, with water-cooled chillers to transfer and recover heat. Using chilled and low-temperature hot-water tanks in this way allows for full heat recovery, so no primary heating plant is required.

The dry air coolers, located on the level 2 façade, reject heat from the water cooled plant in the basement when the heating storage systems are full. We have, therefore, avoided excessive pipework routes to roof level, reducing pumping energy and riser space while keeping the rooftop free of HVAC plant.

Thermal-storage systems offer engineers an opportunity to challenge how new and existing buildings are designed. There could be a more sustainable future in which primary heating plant isn’t needed in office buildings as we push towards net-zero carbon design.

About the author

Joshua Martoo is a senior project engineer at Norman Disney & Young