Baxi Heating heat pump installation

Later this year, CIBSE will publish a new Applications Manual AM16 Heat-pump installations for multi-unit residential buildings. The manual will provide invaluable guidance to designers, installers and building operators looking to apply a range of heat-pump technologies to high-density housing.

AM16 addresses areas of design that are crucial for good heat-pump performance, including: the importance of sizing a heat pump correctly, mitigating the loss of capacity caused by defrost cycles and the impact of lower DHW temperatures on design. These themes are discussed briefly in this article

Green industrial revolution

Across all domestic and non-domestic building typologies, the regulatory and policy landscape is driving a transition away from gas-fired heating systems towards electrically powered alternatives.

Heat pumps currently provide the most energy efficient means of heating a building electrically – and with a decarbonising electricity grid, they also represent an almost universally applicable low-carbon heat source.

If the UK is to attain net-zero carbon by 2050, the Committee on Climate Change (CCC) recommends that 19 million heat pumps be installed. This would mean installing 294,000 each year by 2025 and 714,000 per year by 2028, which ties in with the UK government’s ambition for 600,000 heat pumps to be installed every year by 2028, as part of its Green Industrial Revolution.

The CCC’s drive towards electrification of heating underlines the need for planning and design guidance for the application of heat pumps in the residential sector. The Microgeneration Certification Scheme and other industry bodies already offer a wealth of guidance on the design and installation of heat pumps in individual homes.

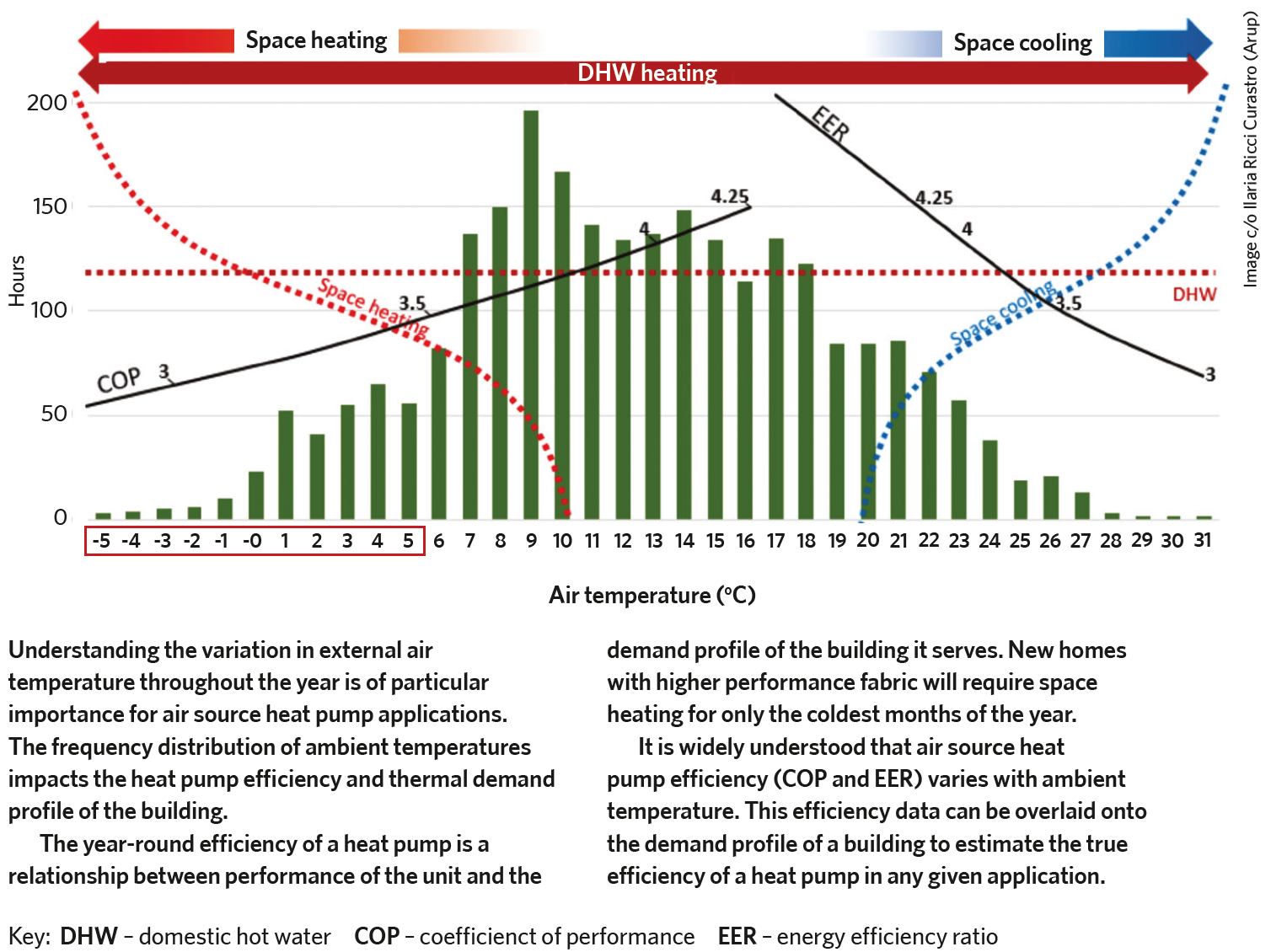

Figure 1: Frequency distribution of ambient temperatures, demand profile of building, and efficiency of heat pump. Image c/o Ilaria Ricci Curastro (Arup)

However, there is currently a lack of specific guidance on the application of heat pumps to multi-residential settings, such as apartment blocks, care homes and student accommodation.

This new Applications Manual brings together best practice and industry-wide advice for the use of practitioners, and addresses the all-important issue of user guidance for a technology that offers a very different experience for residents compared with traditional fossil fuel-powered heating systems.

Arup has been appointed as technical author under the direction of an expert CIBSE Technical Steering Group comprising industry stakeholders and representatives, including developers, designers, installers, operators, manufacturers and building control professionals.

A structured process

The document gives guidance on new-build and retrofit applications, and is structured around a generalised design process and project life-cycle. It consolidates and signposts other best practice, building on existing guidance such as CIBSE CP1 (2020): Heat networks: Code of Practice for the UK.

As well as guiding the reader through the steps of correctly designing and implementing an effective heat pump system, the manual provides useful information on:

- Architectural considerations

- Stakeholder engagement

- Resident user guides

- Capital and running costs

- The state and future of the refrigerant market

- Energy costs to residents

- End-of-life decommissioning.

Experts from Arup and across the industry are contributing to the manual on topics such as controls, commissioning, user-centred design, and the circular economy.

Understanding the technology

This guidance is partly necessitated by the fast-evolving nature of the heat-pump market; with new products, higher efficiencies and novel capabilities emerging on a regular basis. The Applications Manual endeavours to cover the full breadth of heat-pump technologies and applications:

- From in-home heat pumps (such as ambient loop and heat pumps coupled with mechanical ventilation systems) to larger, centralised units serving communal heating networks

- Different heat/cooling sources, such as ground, water and air

- Heat pump capabilities, such as reversible, high-temperature, and simultaneous and independent (or polyvalent) heat pumps.

Defrost cycles

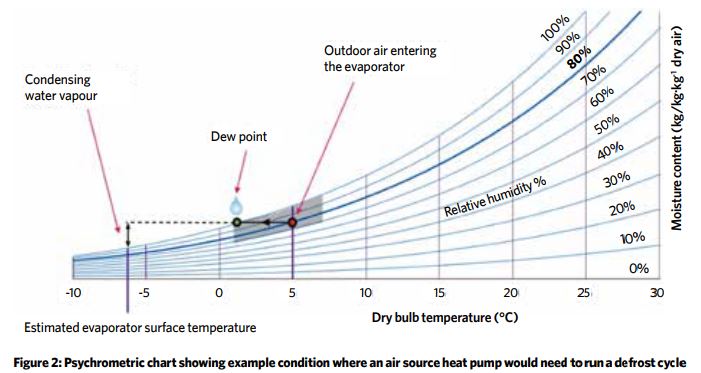

This presents a challenge for all air source heat pumps, which use ambient air as a heat source. When the outside air temperature is around 5-7°C, and relative humidity is more than 70%, the water vapour within the air freezes when flowing through the evaporator, forming ice that accumulates on the coil surface.

To prevent the ice build-up at the evaporator that would otherwise compromise the heat pump’s capability to operate, the heat pump will operate a defrost cycle. During defrost, the ice is melted via a temporary reversal of the refrigerant cycle.

Each defrost cycle can last for up to five or 10 minutes, with up to 3-4 defrost cycles per hour under full-load and certain ambient conditions. Heat pumps can lose some or all of their heating capacity for this period of time, so the design must be able to mitigate this loss of capacity.

The applications manual explains:

- The difference between gross and integrated capacity of a heat pump

- Sizing heat-pump arrays to mitigate the impact of defrost cycles

- Sizing buffer vessels and thermal stores to overcome the effect of defrost cycles.

All about temperature

In new-build residential developments with high-performance fabric, domestic hot water (DHW) represents an increasing proportion of a building’s energy use. The provision of DHW also drives the output temperature of the heat pump and often dictates the peak output of a heat pump or communal system.

A recently published guidance note from CIBSE consolidates the legislation and guidance around DHW temperatures and delivery times in instantaneous systems (such as heat interface units). Key findings are that:

- Generating instantaneous hot water at a temperature of 50°C satisfies the requirements to reduce the risk of legionella growth and minimise the risk of scalding

- Delivering instantaneous hot water to the kitchen tap at a minimum of 45°C within 45 seconds of opening the tap to full flowrate demonstrates an acceptable service level for users and sets a requirement that also limits water use.

This unified guidance on DHW temperatures is key to unlocking the full efficiency of any heat pump that serves an instantaneous DHW system.

Correctly sizing a heat-pump system

In contrast to fossil-fuel boilers, the capacity of a heat pump must be closely matched with the demand it serves. Residential loads are highly variable, throughout the year and across any given day, making this a challenging requirement to meet.

If undersized, the system may fail to heat rooms or DHW to the required temperatures. If a secondary heat source is available (an immersion heater, for example) these may run more than intended, driving up energy consumption, emissions and running costs.

Conversely, if fixed-speed heat pumps are oversized, they will short-cycle at part load, impacting system efficiency. Most inverter-driven units will also see a reduction in efficiency when operating at part load, but not to the same extent as fixed-speed units.

The higher marginal capital cost and space taken by an oversized heat pump underlines the importance of accurately determining the required capacity.

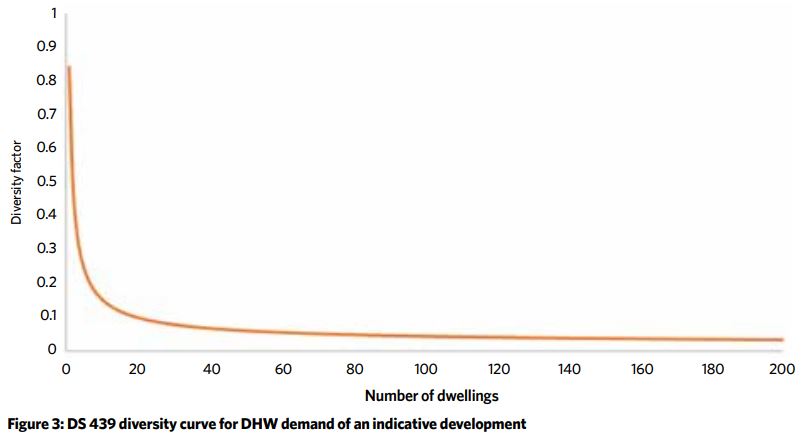

The Applications Manual reiterates the importance of correctly accounting for diversity, particularly of DHW demands, in centralised systems.

The updated CP1 (2020) provides an invaluable reference to an English translation of the Danish DS 439 standard, which readily allows designers to exploit diversity values as low as 2-3% of the connected load (see Figure 3).

The guidance also provides information on how to size buffer vessels and thermal storage, which can provide: System stability, management of defrost, peak lopping, heat sharing and resilience

AM16 Heat-pump installations for multi-unit residential buildings will be released shortly and will be a valuable resource for building designers and operators, as well as heat-pump installers, guiding practitioners in the successful application of this evolving technology to the residential market.

Joshua Bird is a senior engineer at Arup

Acknowledgements

CIBSE would like to acknowledge the support of the NHBC Foundation in the production of this publication.