Pea shoots, garlic, coriander, fennel and chives are grown at the urban farm Credit: iStock.com/Madeleine_Steinbach

Beneath the busy streets of Clapham, in south-west London, an innovative and award-winning urban farm is thriving in energy efficient growing conditions, in tunnels 37m below street level. Growing Underground is an expanding business that is benefiting from a rewarding collaboration between industry and academia.

Launched in 2013, and located in former World War II air-raid shelters leased from Transport for London, Growing Underground uses hydroponic systems to produce sustainable, pesticide-free crops of micro greens and salad leaves.

The aim is to bring edible crop production to the heart of the city and minimise the carbon impact of food transportation. Fennel, garlic, chives, pea shoots and coriander, among other plants, can be picked and on a restaurant plate within hours. Growing Underground – which sells its greens through Ocado, Marks & Spencer and Waitrose – aims to be carbon neutral, and was awarded the 2017 BBC Farming Today Future Food Award.

Growing Underground is based in World War II air-raid shelters

Urban farming is on the increase; rapid growth of the industry in Japan and South-East Asia has resulted in a rise of dedicated plant factories. This has been accompanied by a growing interest in biophilic design in the built environment.

Nature-based solutions – such as incorporating plants in and around buildings – are increasingly being applied to improve the urban landscape, as well our health and wellbeing. As these trends grow, however, it is important to be able to quantify the impact of plants, which can help improve air quality in terms of temperature, humidity and CO2 levels, and contribute – in less tangible ways – to individual and community wellbeing.

Since 2015, a team from the University of Cambridge’s Energy Efficient Cities initiative (EECi), led by Dr Ruchi Choudhary, has been collaborating with Growing Underground since 2015, building on the success of an earlier project at the Royal Botanic Gardens in Kew. A retrofit study of the greenhouses there resulted in the development of a simulation model that incorporated the heat and mass transfer associated with plant transpiration into a dynamic energy simulation of the greenhouse structures.

The initiative’s collaboration with Growing Underground has presented an ideal opportunity to gather data on the impact of plants on air quality under controlled conditions, and for further development of the simulation tool. Since the link-up, a range of wireless instrumentation has been installed in the farm’s tunnels to monitor temperature, humidity, C02, air velocity and light.

‘Our monitoring is helping Growing Underground to optimise yield, while reducing energy consumption,’ says Melanie Jans-Singh, EECi PhD student investigating the integration of urban farming in cities by reusing wasted resources. ‘If, for example, there is a doubt about how the plants are growing at a certain spot, I can refer to the measurement of air velocity to identify the precise conditions. When the plants are growing better in one area than another, the instrumentation helps us to work out why.’

For the growers, access to real-time monitoring enables immediate action when conditions tend towards the sub-optimal. For example, environmental management of the tunnels depends on adequate ventilation via the installed extraction fans – and ventilation is a significant energy consumer at Growing Underground. The monitored data has allowed adjustments to be made that have cut consumption for ventilation without affecting yield.

The analysed data itself is also of value – it creates a ‘lifetime performance passport’, which is a rich source of information for the asset owners, present and future. Data collected from the instrumentation are also critical for informing a heat and mass transfer model of the tunnel developed at the university. This work was presented at the recent CIBSE Technical Symposium.

LED grow lights contribute the only heating to the tunnels

Environmental conditions result from complex 3D interactions between the plants and their surroundings, but the typically regular structure and layout of this farm means an appropriate approximation to consider heat and mass transfer is a one-dimensional slice, vertically through the greenhouse layers – for example, the floor, internal air, tray, growing medium, plants and roof.

Plant transpiration contributes to the air temperature and relative humidity by taking heat from the air to enable evaporation of water from the leaf surface. This is included in the model, in addition to the more standard heat-exchange terms arising from conduction, convection and radiation, and mass exchange arising from evaporation from the growing medium and ventilation exchange.

Transpiration rates – and, therefore, cooling rates – are dependent on the leaf area index for the plants. This is the ratio of leaf area to planted area, and varies depending on the type of plant, growth stage and pruning or harvesting regimes employed. At the Clapham farm, it is a particularly difficult quantity to estimate because, at any one time, there are many different crops, all at different stages of growth.

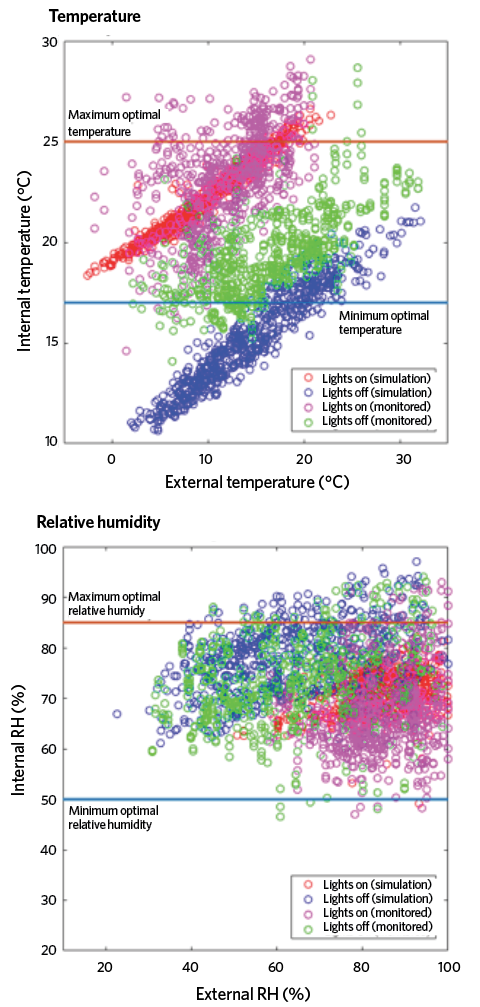

Figure 1: Internal temperature (a) and relative humidity (b) as a function of external conditions

The air’s temperature and moisture content is also critical, because transpiration is driven by the difference between the moisture content at the leaf surface and in the surrounding air. Even with a relatively simple 1D model, however, reasonable results can be obtained for prediction of internal temperature and relative humidity, given the external weather conditions.

Figure 1 shows how the model compares against monitored data for these two parameters. The blue and red points show the model results when the LED grow lights are off and on respectively, and can be compared with the monitored data points in green and pink.

The LED grow lights contribute the only heating to the tunnel. Interestingly, the tunnel location means it is feasible to have the lights switched on at night-time – when, typically, it is cooler outside – so helping to maintain stable temperatures.

Also shown in Figure 1 are the desired operational conditions. The growers keep temperatures above the minimum by altering ventilation rates and closing doors. These actions are not included in the model – hence the discrepancies between monitored and simulated temperatures for low external temperatures.

The simulation tool also includes a model of CO2 exchange. Carbon dioxide levels have only a minor impact on transpiration rates, but are significant for plant growth and, so, critical for an urban farm. CO2 exchange is a complex process, however, and appears to be very dependent on the type of plant; much lower CO2 levels were observed in the farm than would be predicted by the model. Further research into this aspect is a priority for future studies.

The model has the potential to be developed for use in building-energy simulation, to analyse the impact of plants on building internal environments, incorporating natural lighting and enabling quantification of the co-benefits between plants, buildings and the occupants.

The vision of the team at the University of Cambridge is to develop the tool as a means to simulate the impact of plants at the design stage for all types of building

The University of Cambridge team’s vision is to develop the tool as a means to simulate the impact of plants at the design stage for all types of building. In the longer term, the EECi would like to identify the conditions required to turn a space into a greenhouse, to quantify the potential for re-use of derelict space within cities for urban farming, and to develop a metric for quantifying the benefits of plants.

Collaboration between business and academia benefits all stakeholders. Growing Underground is offering a case study for further research, and the EECi team is delivering data that will help the crops – and the company – to flourish.

■ The EECi team is grateful for the support of Growing Underground.

■ Rebecca Ward is a research associate at the University of Cambridge Energy Efficient Cities initiative