Elmgrove Primary School – external grilles view

Monodraught’s HVR Zero ventilation unit was the outright winner of the Product or Innovation of the Year – Air Quality at the CIBSE Building Performance Awards (BPA). Judges praised the level of in-depth research and development that minimised in-use operational energy while optimising comfort. The attention paid to embodied carbon in the product’s development was also commended by the judges, who thought all manufacturers should be assessing the challenge of net zero over a product’s lifetime.

The HVR Zero hybrid ventilation with heat recovery range sets a new benchmark for the future generation of low energy hybrid ventilation systems that integrate heat exchange ventilation strategies. Monodraught claims that the systems consume 90% less energy compared with a typical mechanical ventilation and heat recovery system. The BPA judges said the product challenged traditional centralised air systems in terms of control and efficiency, and that this was, in part, achieved through a well-developed and intuitive user interface.

The system is designed to allow natural ventilation, hybrid mixing ventilation, and low-energy mechanical ventilation with heat recovery through multiple, selectable, segregated internal airways. Each system operates autonomously to ensure that every area has the optimum air quality and correct thermal comfort conditions. During the summer, hybrid ventilation switches on the mechanical fan to boost the natural ventilation and optimise indoor comfort. During winter periods, the system mixes warm internal air with fresh external air to deliver mixed tempered air, while using heat recovery to save energy.

The HVR Zero systems installed in classrooms

Monodraught’s product has been targeted at schools in particular, where indoor air quality (IAQ) can affect the health, comfort and productivity of students and staff. Poor IAQ can lead to a variety of health problems, such as headaches, fatigue, and aggravation of respiratory conditions.

Most people spend about 90% of their time indoors, and studies indicate that indoor levels of air pollutants may be two to five times higher than outdoor levels. Young people are more vulnerable to the effects of this exposure than adults, with reduced classroom air quality causing a reduction in cognitive performance and presenting a safety issue for the health of the pupils.

In summer, hybrid ventilation switches on the mechanical fan to boost natural ventilation and optimise comfort

The British Council for Offices Guide to Specification 2019 states that ventilation should supply 8 litres of fresh air per second per child, and 10 litres per second per adult, totalling 260 litres per second per average classroom. This will keep the CO2 concentration levels as specified in BB101 and CIBSE Guide A.

Since the development of HVR Zero, Monodraught has supplied approximately 200 school projects with these systems. The system was included in a new-build sports hall and classroom block at Holmer Green Senior School in Buckinghamshire. Data monitoring since the installation has shown that the systems are performing strongly, with low running costs and excellent air quality, and temperatures maintained at an average of 21°C during occupied hours. ‘Staff and students enjoy the fresh and comfortable spaces with minimal impact on the aesthetic appearance of the classrooms and no need to constantly adjust the controls for individual comfort requirements,’ said Gareth Thomas, mechanical project manager at Whitehead, project contractor.

Both hybrid and natural ventilation solutions were provided to the school. The HVR Zero systems were installed throughout the classrooms, halls, and corridors, but natural ventilation systems were selected for larger spaces, such as the sports hall.

Provision of sufficient fresh air to buildings is essential to meet regulatory standards. BB101 is a set of guidelines, developed in 2006 by the UK Department for Education, that gives recommendations for the design and construction of school buildings that offer comfortable and healthy indoor environments to support learning and wellbeing. Revised in 2018, BB101 (2018) places tougher demands on ventilation strategies. Hybrid ventilation is now suggested to meet more stringent temperature and carbon requirements.

Monodraught provided ventilation to a new-build sports hall and classroom block at Holmer Green

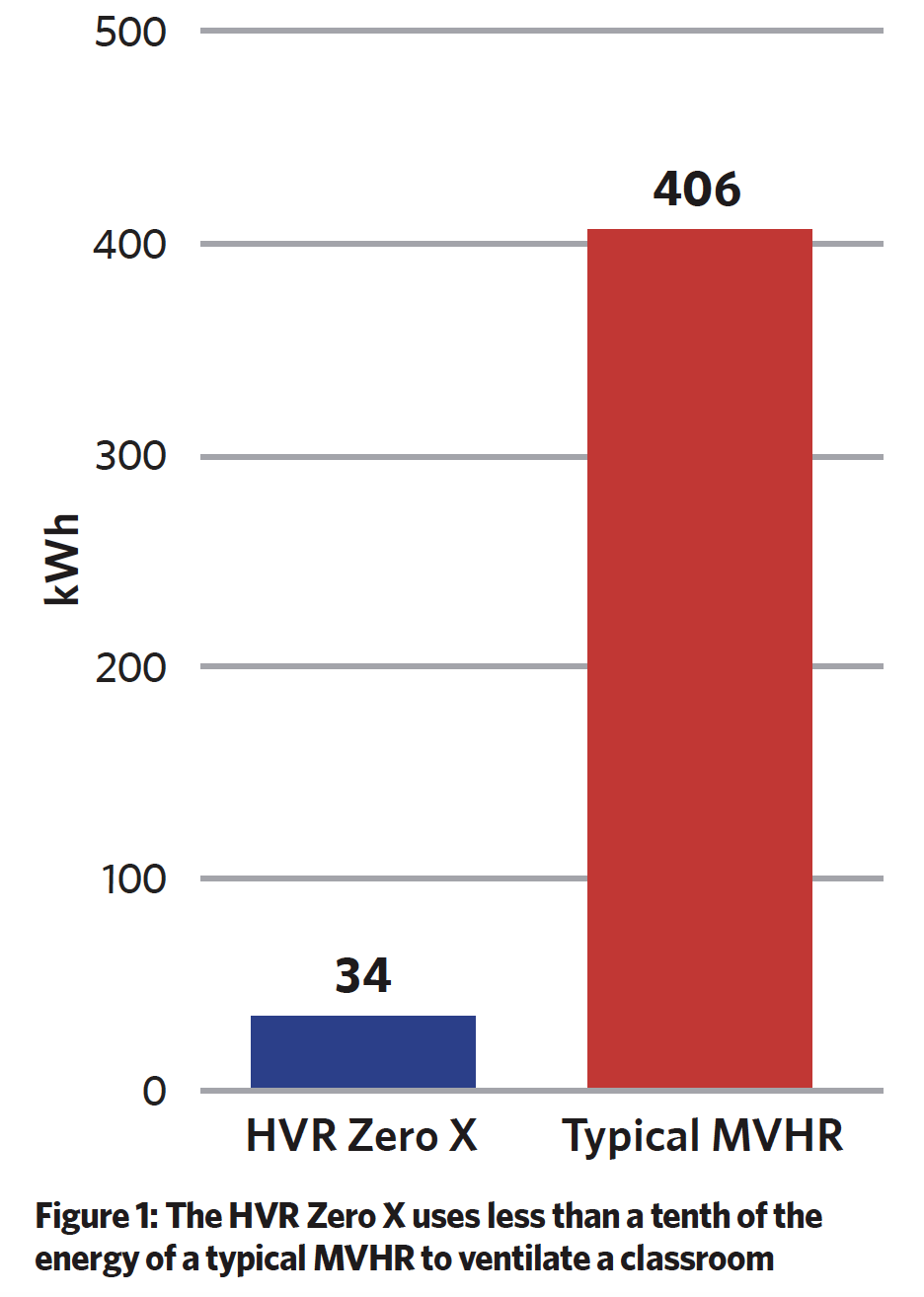

Monodraught conducted an energy and running costs comparative analysis of HVR Zero v MVHR systems, which details the ventilation energy required to keep a typical South East-based classroom to BB101 standards. The report compares the carbon emission impact and energy usage of a traditional MVHR installation with the HVR Zero X hybrid ventilation system, with optimised heat recovery core, in a standard theoretical classroom of 60m2 with 32 occupants.

Figure 1 shows that the HVR Zero X system requires less than 10% of the energy of a typical MVHR system to ventilate a classroom. A large amount of energy is required to ventilate through a high-efficiency heat exchanger, which is designed for extremely low external temperatures of less than -5°C. However, very few occupied hours ever reach this temperature, particularly in the south-east of the UK. Consequently, ventilation systems are typically over-engineered, resulting in energy losses year round as the heat exchangers are used unnecessarily or the inefficient bypass modes are used, which have the same specific fan power (SFP).

Typical MVHR systems have an SFP of approximately 1 W.L-1s-1; the HVR Zero X system has an industry-leading average SFP of 0.09. Further, a running cost saving per classroom of more than £1,400 across 10 years was calculated.

HVR Zero can be used in single-sided or cross-flow ventilation strategies. The leading edge of the system uses the principle of an owl’s wing to accelerate and decelerate the distributed ventilation air. This unique design reduces the audible noise of the movement of the ventilation air. It also has intelligent controls as standard, and inbuilt temperature and CO2.

Targeting zero embodied carbon

HVR Zero is the first hybrid heat recovery system of its kind with zero embodied carbon. The materials used have been specially selected to minimise embodied carbon, and to ensure they are fully recyclable at end of life, supporting the circular economy. The residual embodied carbon is then offset via an independently accredited gold standard scheme.

Life Cycle Assessment methods were used to calculate the embodied carbon and quantify the residual CO2 for offsetting purposes. The carbon emissions were calculated with the IPCC 2013 GWP 100a method, using established life-cycle inventory databases Ecoinvent 3 and USLCI, and the CIBSE TM65 embodied carbon mid-level calculation method. It was concluded that the total carbon footprint of each HVR Zero system is 256kg CO2 equivalent. To build resilience in the calculation, 300kg of CO2 was offset.

Monodraught partners with a UK-based tree-planting scheme, Ecologi. For a typical secondary school comprising 50 classrooms, with two HVR Zero systems in each, 30 tonnes of CO2 is offset, and 100 trees are paid for and planted. This is equivalent to 30 long-haul flights, 90m2 of sea ice saved, or 70,000 miles driven in a car.