The Urban Sciences Building (USB) at Newcastle University has been designed to improve our understanding of the relationship between buildings and their wider environment. As such, it is wired to more than 4,000 sensors to allow academics to see how it performs and how it interfaces with the energy, water, internet and other networks to which it is connected.

The £58m building, which opened in September 2017, is home to the National Green Infrastructure Facility, the National Centre for Energy Systems Integration, the university’s School of Computing, and a series of research laboratories with an agenda to inform future urban infrastructure.

It has been designed for teaching, hosting events, laboratory research and – crucially for the university – as a facility in which to test smart technologies to promote urban sustainability. In short, it is a living laboratory.

Project team

Client: Newcastle University

Mechanical, electrical, structural, fire and acoustic engineers, and client sustainability adviser: BuroHappold Engineering

Architect and interiors: Hawkins\Brown

Contractor: Bowmer & Kirkland

MEP contractor: NG Bailey

Client sustainability adviser: BuroHappold

Contractor sustainability adviser: DSSR

Project manager: Turner & Townsend

‘There was a lot of engagement with the academics who would be using this project. They were tasked with coming up with research projects to establish the technologies that had to be installed at the outset, or that could be bolted on in the future,’ says Mark Dowson, an associate at BuroHappold Engineering, the scheme’s MEP engineers.

The building is also a testbed for sustainability. As well as achieving Breeam Excellent (with a score of 78.1%), bespoke and auditable sustainability targets were developed by BuroHappold to drive sustainability beyond Breeam. These additional elements covered design, construction and in-use aspects of the building.

‘Achieving Breeam Excellent does not necessarily result in a low-energy building,’ says Dowson. It is a fact of which the university is only too aware, as one of its other Breeam Excellent buildings has a Display Energy Certificate (DEC) rating of F. To ensure USB performs as the designers intended, it is undergoing three years of post-occupancy evaluation (POE) as part a soft landings initiative.

Real-time visualisation of the building

The USB is the centrepiece of a new development called the Helix, being built on the former Scottish & Newcastle Brewery site in the heart of Newcastle. A triangular-shaped, six-storey building – facing onto a new square – its 12,800m2 of teaching, research and laboratory space form two sides, while a giant, glazed atrium links these two blocks to complete the triangle.

The atrium contains the main entrance and incorporates a lecture theatre, a ‘forum space’, ‘showcase labs’ and a cafe. A staircase leads occupants through ‘creative collision’ spaces to the quieter research labs, alongside of which are the Urban Observatory and Decision Theatre. These spaces are used to process the huge amounts of data collected by sensors positioned throughout the building and across the city.

Unfortunately for the building services engineers, the glazed atrium faces south. ‘It had to point towards the heart of the masterplan, which meant we had to do extensive parametric analysis to optimise the shading and glass performance,’ says Dowson.

Modelling resulted in the addition of a digital artwork to the atrium exterior. This comprises a series of lines, circles and dots – a composition that, according to the scheme’s architect, Hawkins\Brown, ‘represents the information resources in the university’s websites, including their myriad networks and layers of connections captured at a particular moment in time’.

Whatever the design rationale, the artwork ensured the glazing met the required g-value so that comfort conditions could be maintained in the space without mechanical cooling. Instead, openable vents – at low and high level in the façade – allow air to flow through the space, and are controlled on temperature and CO2 concentrations in the space. An underfloor low-temperature heating system keeps the atrium comfortable in winter. Sensors embedded in the concrete floor slabs measure their temperature and the data is used for academic studies on thermal mass and associated night-time purging.

Initially, the engineers explored an all-electric building services solution, to future-proof the facility against changes to carbon factors. Low-NOx gas condensing boilers were added as the design progressed, however, to supply top-up heat to the heating and domestic water systems. ‘The POE studies show it to be about 90% electric,’ says Damian Wines, associate director at BuroHappold.

Beyond the atrium, environmental comfort for the majority of research and teaching spaces is provided by active chilled beams, which supply cooling and fresh air, and are connected to a water-to-water heat-pump system. Heating is from a perimeter system. Domestic hot water (DHW) is preheated from a water-to-water heat pump and there is a low temperature hot water (LTHW) top-up boiler. Comfort in event spaces is maintained by an all-air system.

The systems are controlled in HVAC zones that are strategically arranged, with sizes minimised to maximise future flexibility. HVAC systems ramp up or down depending on occupancy, CO2 and temperature, to save energy. All permanent workspaces have natural daylight and opening windows.

On the roof of the building is a solar photovoltaic (PV) array that gives the building a source of renewable electricity. In addition, the roof holds innovative photovoltaic-thermal (PVT) hybrid solar collectors, generating electricity and thermal energy.

Last year, the energy generated from the solar PV and PVT panels was 23.6MWh and 8.5MWh respectively – equivalent to energy savings of £3,200 per year. While this benefit is small, the value created through integration into the energy-storage testbed has secured £170,000 of funding from the Engineering and Physical Sciences Research Council for a project on building demand response.

The renewables are connected to an energy-storage test bed within the building, which includes a DC microgrid and smart technologies, such as micro metering of electricity and water, and regenerative lifts.

Urban water research

As home to the National Green Infrastructure Facility, the USB project is a unique, £10m urban water research and demonstrator facility on the Helix site. Next to the building are full-scale sustainable drainage system (SuDS) demonstrators and experimental swales that can test the impact of attenuation, ‘leaky barriers’ and natural flood management during simulated heavy rainfall. Large-scale modular lysimeters are installed as green infrastructure to measure evapotranspiration.

The research facilities perform scientifically sound and repeatable experiments, to demonstrate at large scale how these might be used in cities, altering the way we consider key water issues that are vital to urban sustainability. The facility can hold 600m3 of water and is capable of handling 50mm of rainfall in one hour – more than during the 2012 ‘Toon Monsoon’.

Live monitoring of SuDS infrastructure – including soil moisture and water levels – can be seen on the Urban Observatory monitoring website. This also contains data from 1,035 sensors across the Helix site and the city of Newcastle, including weather, noise, air quality and traffic congestion.

A 30kW vanadium redox flow battery will be installed by the university next year, to enable further research into intelligent energy storage. The addition will turn the Helix site into the UK’s first electrical smart grid storage demonstrator project. This important research will investigate how the USB, and other buildings on the Helix campus, can be aggregated to give resilience to the grid through shedding and shifting non-critical, time-deferrable loads. Planning applications for two integrated, super-charging electric vehicle (EV) filling stations – of 175kW total capacity – have also been submitted.

The building itself is monitored by thousands of smart and micro sensors, which, in tandem with connections using open internet protocols, feed the control systems that ensure optimum building operation. To meet the stringent data-collection specification and resolve the challenges of finding BMS suppliers, the university adopted a strategic research partnership with Siemens. The controls will learn how the building is used and will respond by fine-tuning its energy needs.

The scheme was developed in BIM, and the BIM model is now helping with the operation of the building and showing the conditions recorded by each of the sensors (for real-time data, see: 3d.usb.urbanobservatory.ac.uk).

Unusually, the scheme has three (4m x 3.5m x 4m high) plantroom modules per floor, each capable of being monitored and controlled independently. The modules are stacked on top of each other to form three towers, reaching from the ground floor to the roof. Mounted on the roof, above each plantroom stack, is a dry air cooler to reject waste heat. The 18 plantrooms are intended to allow different zones, cores and floors to be more closely controlled and switched on or off as part of research into time-deferrable, load-shedding initiatives. Such modularisation means maintenance costs are lower over the lifespan of the building, says Dowson.

As part of the additional sustainability targets set at the outset of the project, the contractor was required to calculate the embodied carbon for the building, including all MEP systems and construction-site activities. However, none of the 13 MEP product manufacturers were able to provide Environmental Product Declaration certificates, so material quantities had to be calculated using the BIM model. The total embodied CO2 was found to be at least five times higher than one year of operational CO2 emissions.

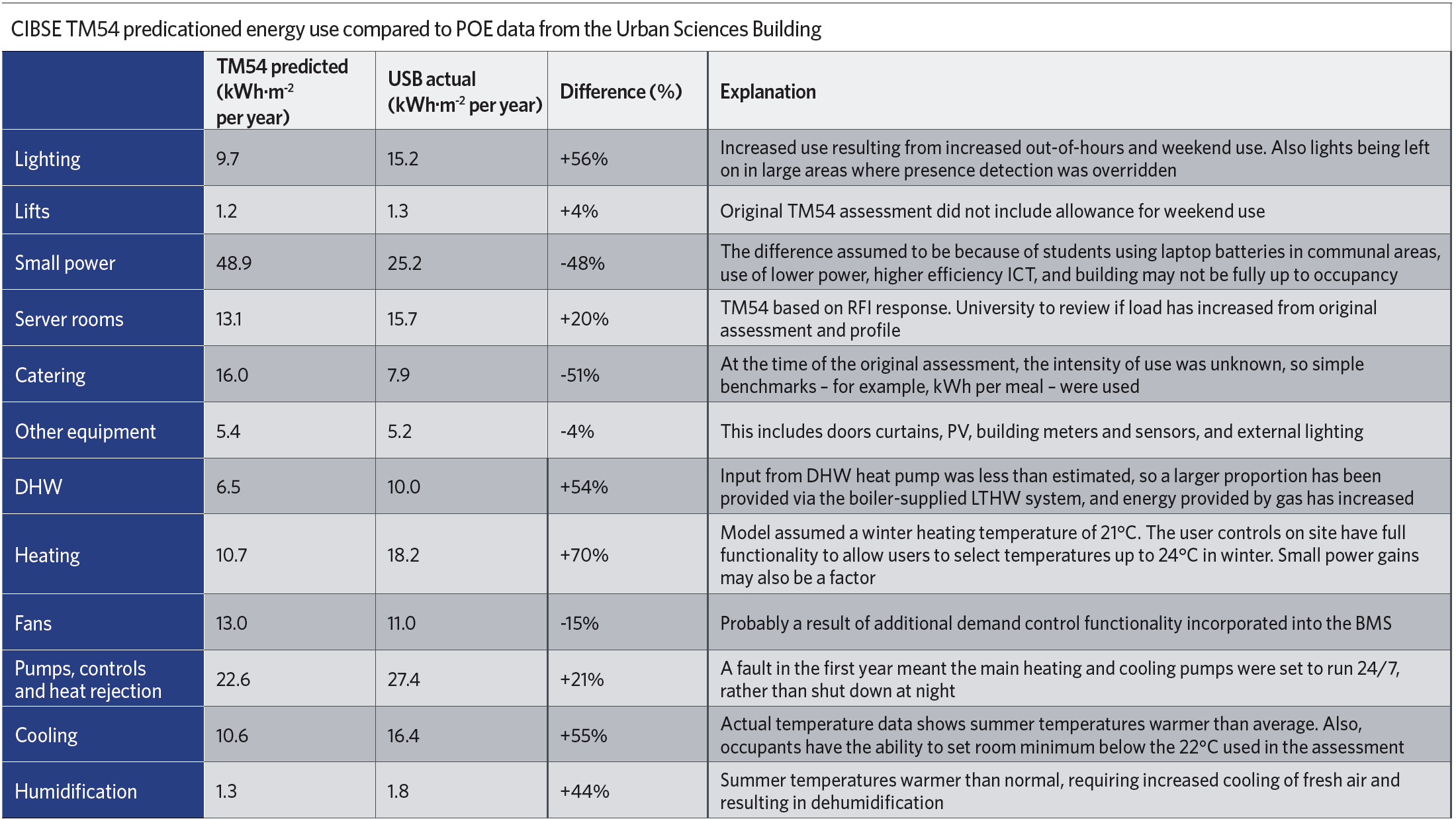

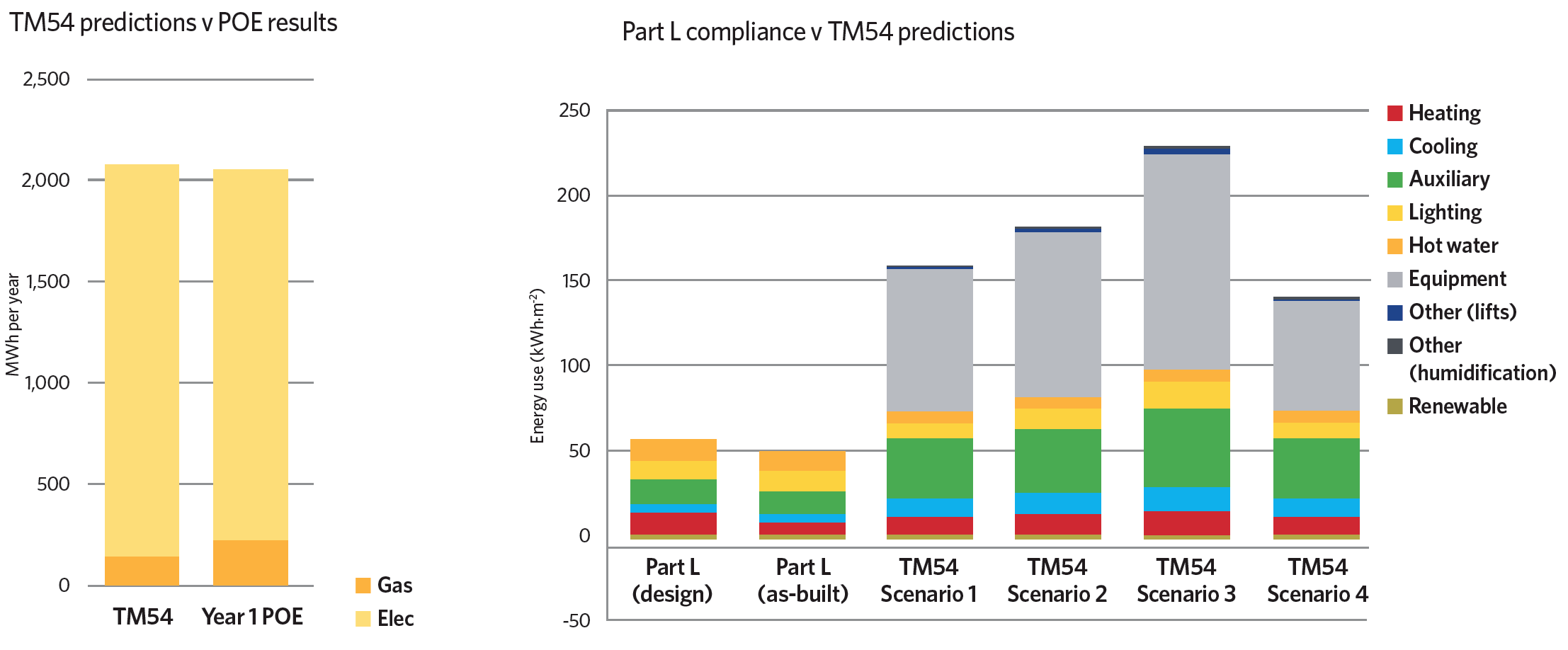

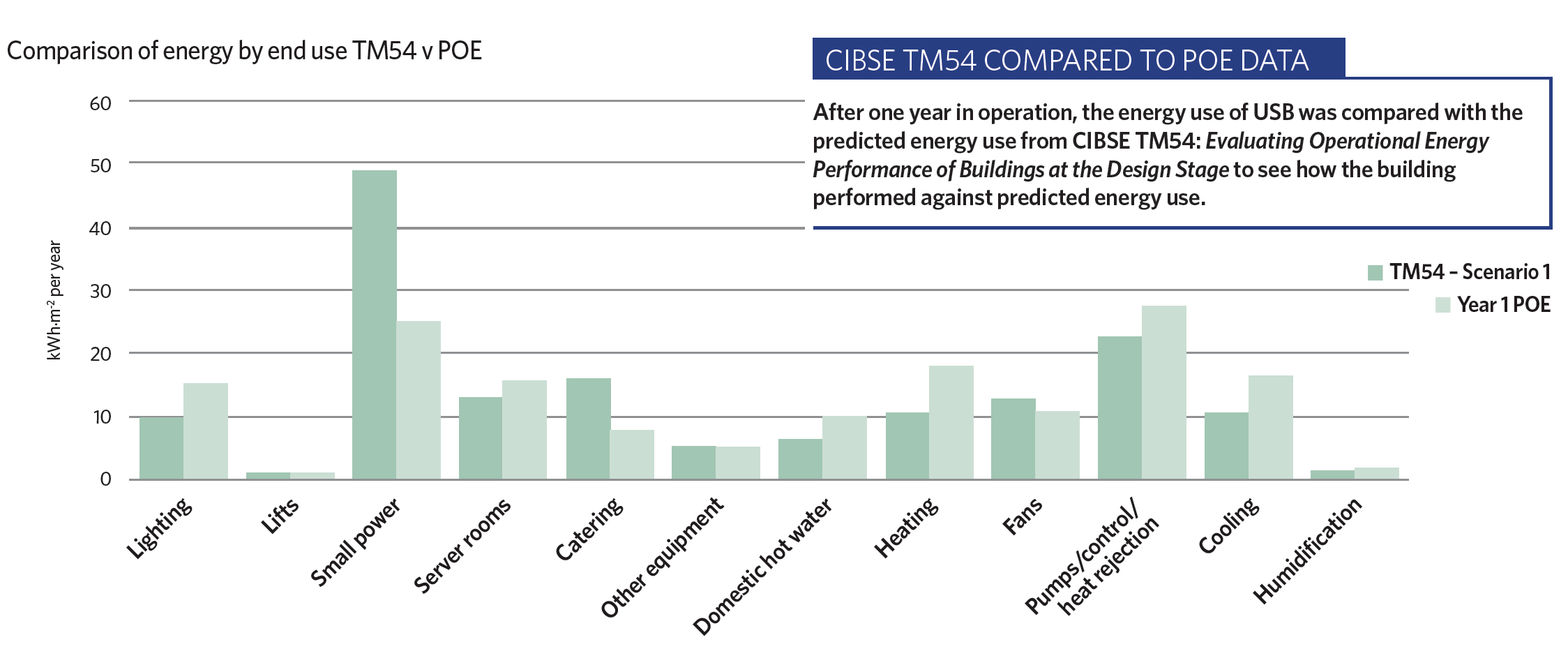

The building’s total energy usage was predicted by NG Bailey, using CIBSE TM54 at the design stage, to be 140.6 kWh.m-2 per year for electricity and 16.1 kWh.m-2 per year for gas – equivalent to a DEC D. By comparison, Part L compliance figures were more than three times smaller, at 40 kWh.m-2 per year for electric and 7.1 kWh.m-2 per year for gas – which, Dowson says, is ‘a good illustration of why Part L should not be used as a prediction for in-use energy performance’.

In addition to the baseline operational energy prediction, two further TM54 operational scenarios were run, resulting in DEC ratings of D (98) and E (125), depending on how the building and systems were used. Scenarios to achieve a C (75) rating were also prepared, to give the university an idea of how it would go about achieving this performance.

‘These gave the university confidence in understanding what end product it was actually going to get, which is rare in the industry,’ says Dowson. It should be noted that the DEC benchmark of D (100) is based on a naturally ventilated university campus building, whereas the USB is fully air conditioned and houses a number of process-based activities.

After a year, the POE showed that the building had actually used 129.9 kWh.m-2 per year of electricity and 22.5 kWh.m-2 per year for gas. ‘Impressively, the total energy use was 152.4 kWh.m-2 per year, which was within 3% of the baseline TM54 prediction,’ says Dowson. The figures showed the building had used less electricity than TM54 had predicted, but more gas.

With the POE data in place, the design team can offer targeted advice to the university to try to achieve a DEC C rating for next year, with an aspiration to aim for a DEC B the following year. ‘From our current position, a DEC C rating would require a total CO2 reduction of 6.5%, which should be achievable, and a DEC B would require a 33.5% reduction in total CO2 emissions,’ Wines says.

One year after occupation, a Building Use Studies (BUS) survey was done, and the results compared with the BUS dataset and against the three university buildings where the USB’s occupants were based previously.

The USB building scores better than the BUS benchmark mean and BUS-scale midpoint for all criteria, with the exception of BUS benchmark mean for noise. Some survey comments suggest the USB’s open-plan spaces, which allow it to be easily reconfigured, are not universally popular: ‘The offices were supposed to encourage collaboration, but they stifle it because some people want absolute silence, was one comment.’ Others have praised the design: ‘This area’s large, open layout makes it easy to find and communicate face to face with my colleagues’ and ‘the atmosphere is conducive to working.’

The survey reported that 71% of users in the USB find its design makes it easier to collaborate and 76% said it was simple to find a workspace that suited their activity. Dowson believes USB will score better in subsequent surveys because, in the first year of occupation, snagging was taking place, which affected comfort and productivity. ‘Further, directly in front of the USB is an active construction site, so this impacted on some of the noise scores,’ he adds.

With two years of soft landings to run, and the building’s 4,000 sensors, there is plenty of scope to fine-tune the USB’s systems and to optimise its already impressive energy performance still further.