Credit: iStock.com / Monkeybusinessimages

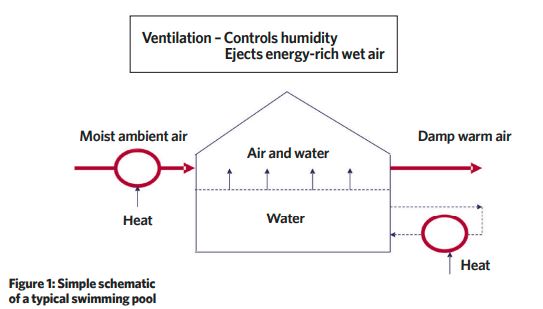

People of all ages enjoy going to the swimming pool for sport, therapy and recreation. However, energy use in wet leisure centres and hotels with indoor pools is often higher than expected. This is because a lot of energy is used to heat the pool water to a comfortable temperature, and this gives rise to quite high levels of evaporation into the air of the pool hall.

Ventilation is used extensively to remove the damp air and so prevent damaging condensation on cold surfaces, but the net effect is to remove the energy from the building as waste latent heat. For many designers and operators, obtaining the best results is something of a black art.

We became involved in helping to reduce the energy use in leisure centres and swimming pools several years ago. Some were very well run and had the latest equipment, but, in others, we came across a number of common problems.

Very often, the ventilation ran flat out all year round, both day and night. This was generally because no-one understood how to control it and no-one was willing to take the risk of tampering with the settings. Doors and windows were often left open and warm, moist air penetrated well beyond the pool hall.

Pool covers, which are meant to reduce evaporation overnight, were not used, and heat-pump energy-recovery systems remained unrepaired and out of service. We witnessed numerous cases of CHP engines either broken down and abandoned, or requiring heat to be discharged from rooftop radiator panels in summer to meet contractual operational demands.

Other observations included the relatively poor design and condition of the buildings, especially of older properties, with many showing the ruinous impact of condensation on structural steelwork. Undaunted by the challenges, we decided to try to model them, because we needed to be able to justify, financially, the improvements we were recommending.

Swimming-pool modelling

When we first looked at the pool halls as conventional dry buildings, we found the conductive heat losses were only a fraction of the total heat input. So, we needed to understand how to account for the majority of the energy use.

We began by researching what had already been done and came across some interesting work carried out by a group of US researchers,1 who tried to establish the rate of evaporation from indoor and outdoor pools. They took measurements, and related them to the number of people in the pool and the speed and humidity of the airflow over the surface, air temperature and other factors. We built these findings into the heat and mass balances over the pool system.

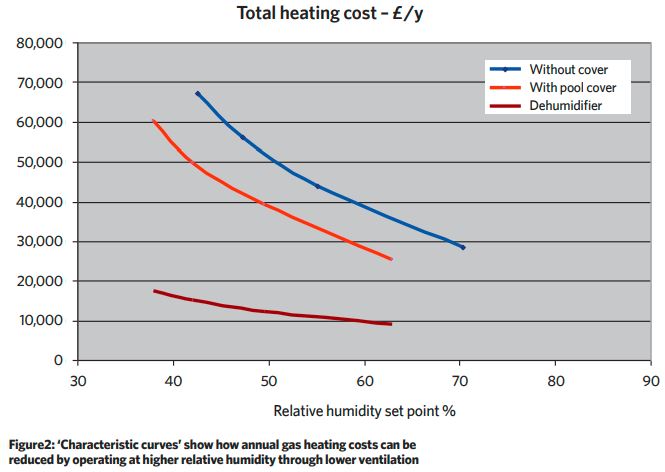

Our clients were keen to know the implications of any changes on the annual cost of operations, so we represented the resulting output as a set of ‘characteristic curves’ for any given pool. These show how costs can be reduced by cutting the ventilation rate and allowing the relative humidity (RH) to rise.

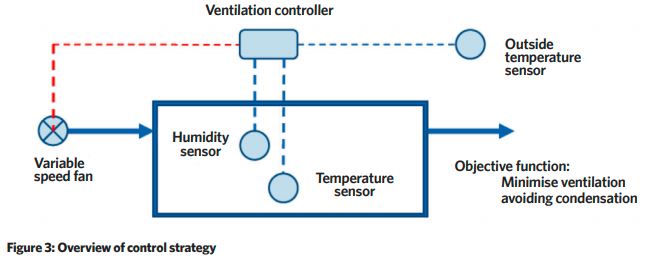

The optimum ventilation level is that which is just sufficient to prevent condensation. This varies over time with pool activity and outside temperature, so it is really important that ventilation is varied to meet the changing conditions. For example, the need for ventilation overnight is much less than during peak bathing periods, and higher in winter, when the walls are colder.

These ‘characteristic curves’ are also very useful in evaluating the annual energy savings from using pool covers overnight, the value of repairing the heat pump recovery systems, and the financial benefits of modern ventilation-control systems.

Ventilation controls

Pools should have variable-speed ventilation systems, controlled in response to humidity levels inside the pool and temperatures outside. These ensure ventilation can be minimised overnight – which is especially relevant if a pool cover is in place – and, at the same time, accommodate the high evaporation levels during busy periods. Seasonal variations in the inside wall temperature also need to be accommodated.

Ventilation is used extensively to remove the damp air and so prevent damaging condensation on cold surfaces, but the net effect is to remove the energy from the building as waste latent heat

The case for improving insulation

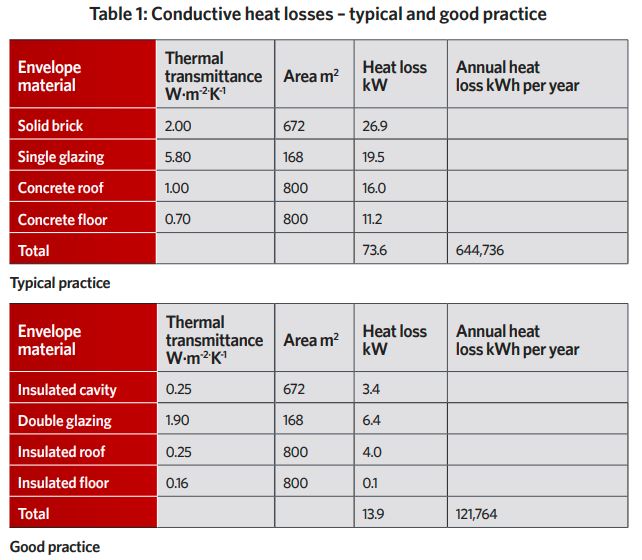

The above characteristic curves do not take into account conductive heat losses through the walls and windows. In the early days, we did calculations to show the impact of improved insulation as if we were dealing with a dry building. Table 1 shows that insulation can reduce the heat lost through conduction (dry buildings) by about 523,000kWh per year, saving heating costs by about £22,300 per year. This is rather small compared with the cost of the work.

Many pool halls are not very well insulated, but the financial justification for installing additional insulation and double glazing is usually not very strong. We came to realise, however, that improved insulation would have a dramatic secondary effect. Better insulation allows the pool to operate at a much higher level of RH and, so, with a much lower ventilation rate, without causing condensation.

We can see from the ‘characteristic curves’ for a typical pool that raising the RH from 50% to 60% saves about £10,000 per year in (gas) heating costs. Our model showed that operating the pool hall at 70%, rather than 50%, would save 550,000kWh per year, worth about £23,400 per year. (At lower outdoor temperatures the RH would need to be lower.)

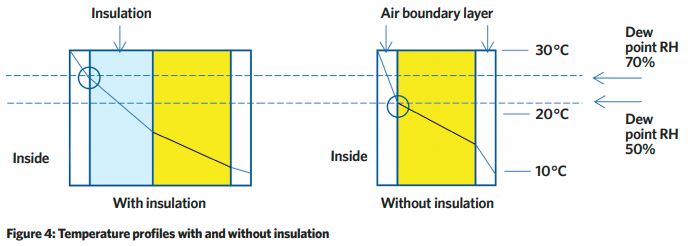

These savings arise through blowing out less warm, energy-rich air containing all the latent heat of the evaporated water. This effectively doubles the financial case for insulation. Figure 4 shows the hypothetical temperature profiles across the pool-hall wall with and without insulation.

When we looked at the temperature profiles through insulated walls, we could see that such a rise in humidity levels is possible. So, the energy savings achievable from insulation could be roughly double the savings in conductive heat losses alone.

This makes the case for improved insulation and double glazing much more attractive. It also highlights the need for new buildings to be very well insulated, and have no thermal bridges, exposed steelwork or crevices where condensation can accumulate.

Summary

Modelling has shown that most of the energy used is extracted from a pool in the ventilation, and the more this can be reduced without condensation taking place, the better. The positive impact of pool covers, deployed overnight, has also been demonstrated.

It highlights the need for new buildings to be very well insulated, and have no thermal bridges, exposed steelwork or crevices where condensation can accumulate

Modelling has highlighted the enormous variation in the evaporation rate during the day and throughout the year, and that a variable-speed ventilation system is needed to accommodate it.

However, the important point is that the best results will arise when well-designed ventilation systems and controls are combined with good building insulation.

About the author

- Mike Hancock is a director at Dee Associates

References:

- Charles C Smith, George O E Löf, Randy W Jones, Rates of evaporation from swimming pools in active use, ASHRAE Transactions 1998 vol 108, pt 1, item 4146, pp1-9, American Society of Heating, Ventilation and Air Conditioning Engineers, Atlanta, USA.